Y-12 Blog

A new scale, left, is now about 10 ft. away from the rolling mill, right, at Third Mill. A forklift manipulator, far right, carries depleted uranium plates to the scale. Before the new scale was installed, the forklift had to travel about 150 ft. to reach the scale.

A new scale at Third Mill shows a project does not have to cost millions of dollars to hold a lot of weight at Y-12. The device was installed in Building 9215, where depleted uranium is processed. The scale cost about $3,000 and has shaved 32 minutes off each individual billet campaign, which translates into many hours saved each year and increased productivity.

The scale replaces an older one that was located more than 150 ft. away from the rolling mill where the billets (bars of metal) are rolled into plates. A forklift with a manipulator carries the individual plates from the rolling mill to the scale to be weighed and then places them on a rack.

The new scale cuts 32 minutes from a metal process. A rack, on which rolled plates are placed, sits on top of it.

Previously, the forklift had to travel down a long hallway to get to the scale, which took a bit of time. The new scale is now about 10 feet from the rolling mill, which reduces travel time for each billet run. A billet yields 16 plates, and the forklift took 2 minutes to transport each plate to the scale, which amounted to 32 minutes per billet run. With the scale now just a few feet from the rolling mill, the drive time is drastically shorter.

In addition to the time savings, the scale has freed up the mill, reduced material handling and movement, and decreased concerns of transporting material through the area. There is more time on the mill for additional work, and the shorter distance to the scale increases efficiency and decreases risk of injury.

Before the new scale was installed, a forklift carrying individual plates had to travel down this long hall to a scale.

Brad Russell, the Sustainable Acquisition Program manager, wants employees to know buying green is more than a saying; it is a way of life at Pantex and Y-12.

As a government contractor, Consolidated Nuclear Security is required to abide by government regulations. One requirement is purchasing sustainable products, which provides opportunities for CNS to make positive choices for the environment.

CNS's newest Sustainable Acquisition Program manager, Brad Russell, is one of those experts guiding those purchases. “It is great when CNS and the sites are recognized for the outstanding work they do in achieving sustainability,” Russell said.

According to Russell, when CNS purchases sustainable products, “we’re not only making better choices, but we’re showing CNS's commitment to our environment. Purchasing sustainable products helps to establish a healthier environment for employees because we’re eliminating products that off gas, like cleaning products, flooring, and paint; reducing the amount of hazardous material on site; and reducing atmospheric carbon dioxide that causes climate change.”

It all adds up because the federal government is the single largest consumer in the world. “Federal sustainable purchasing is a big business,” Russell said. “Products range from remanufactured toner cartridges, post-consumer 100% recycled content paper, green electronics, bio-based cleaning products, compostable or biodegradable food containers, and non-toxic construction material.”

GreenBuy Award Winners

Congratulations to Pantex and Y-12 on each receiving a GreenBuy Award for purchasing achievement in FY 2022.

Pantex received the silver level for purchasing six priority products in four categories.

Y-12 received the gold level for purchasing 10 priority products in six categories.

This fiscal year, Russell and his program have set several goals, including increased purchasing of bio-based and recycled content. “In FY23, we want to introduce at least ten new sustainable products, issue a user-friendly quick reference guide that highlights sustainable products readily available, and replace some flooring [at Y-12] with sustainable flooring.”

When looking to buy products, at work or at home, Russell encourages checking out the product description. “Most items have a description that tells you if it is bio-based or made with recycled content,” he said.

The team tracks purchases of sustainable products at Y-12. “We like to know if you liked it, did not like it, and why. This information helps us in recommending products for future users as well as providing feedback to our vendors.”

The data collected on purchases is also used to track how well CNS and its sites do in meeting those government expectations and to show how the program has grown. Both Pantex and Y-12 have received several awards for purchasing sustainable products, with the U.S. Department of Energy GreenBuy Awards being the most recent example. This program recognizes DOE sites for excelling in their “green purchasing” and going above compliance requirements.

“Being recognized by DOE shows they recognize CNS goes beyond the requirements. The Sustainable Acquisition Program is here to make a difference and figure out what purchases can change and be more sustainable,” Russell said. “Submitting award nominations and being recognized for our efforts is really rewarding.”

Toby Williams, Director of Global Security Analysis and Training (GSAT), tests out an AR headset under the instruction of Avrio Analytics CEO Alicia Caputo.

Training workers in high-hazard jobs safely can be a challenge. At the Oak Ridge Enhanced Technology and Training Center (ORETTC), new training methods will eventually remove many of the obstacles by placing trainees outside the hazard bubble and into virtual environments.

That is one takeaway from the recent Extended Reality (XR) Symposium at the new Emergency Response Training Facility in Oak Ridge.

Subject matter experts from across the Nuclear Security Enterprise (NSE) and industry converged to share ideas on technology training and digital transformation. The center’s array of virtual reality (VR) and augmented reality (AR) tools was on full display as demonstrations and panel discussions took place throughout the facility.

Y-12’s ORETTC Director Ashley Stowe said the goal of the symposium was to increase partnerships and also make participants aware of the potential of these advanced training tools.

“We had almost 60 participants — evenly split between those who’ve used XR at work and those who have not,” Stowe said. “As a result of the symposium, we have commitments to collaborate and interest to apply the technologies.”

Toby Williams, director of Global Security Analysis and Training (GSAT) at Y-12, said one of the goals of the symposium was to learn best practices.

“We wanted to bring together a variety of groups, labs, and sites that are doing work in augmented and virtual reality space and learn from each other about our successes and failures,” Williams said.

Machelle Sumner, GSAT senior program manager and symposium organizer, agreed with Williams.

An XR Symposium attendee tries out an AR headset.

“The XR Symposium gave us an opportunity to strengthen our collaborations with our partners and with the National Security Enterprise (NSE) to continue moving us into the future. With the first building complete at ORETTC, the team is ready to hit the ground running and put this technology to use,” said Sumner.

Representatives from HaptX demonstrated haptic glove technology, which is already being used at ORETTC. This technology is also at the center of new glovebox training being developed for future courses at the facility.

Haptic gloves enable users to feel the virtual environment instead of just seeing it. The sensation of touch adds that extra piece of reality to the training environment.

“The use of HaptX gloves in virtual training environments provides the user with the ability to build muscle memory, both mentally and physically,” said ORETTC Instruction Technology Lead Austin Arnwine.

HaptX was one of several groups to demonstrate its technology. Avrio Analytics brought its immersive AR training platform, designed for high-risk, low-occurrence scenarios. The company has used it to develop single-player drills and exercises and multiplayer tabletop exercises for response training at ORETTC. The University of Central Florida discussed its work on digital twins, which involves creating a digital representation of a building that a user can walk through and explore using AR/VR technology. Again, this form of technology is a facilitative tool when training for high-hazard situations.

Keynote speaker Mark Sage, executive director of Augmented Reality for Enterprise Alliance, shared the bottom line: “AR and VR have the potential to improve safety, increase productivity, lower costs, and enable knowledge to be shared more easily across the NSE.”

ORETTC is a large part of the future Sage describes and a future both Stowe and Williams want to see grow.

“These XR technologies, while powerful, are toys unless we apply them correctly. Everything we do at ORETTC funnels technology through an educational lens so that we are using the correct technology in the correct way at the correct time to achieve the learning outcome we desire for our customers,” said Stowe.

“Training using AR and VR technologies is happening, and I am excited to know we are helping to close the gap and leading the way in this area,” Williams said.

Machelle Sumner, Global Security Analysis and Training (GSAT) Senior Program Manager, kicks off the XR Symposium with a presentation in one of ORETTC’s training classrooms.

Courtney Edenfield contributes to the mission as a technician in Analytical Chemistry Mission Operations at Y-12.

Take 5 minutes and learn about Courtney Edenfield, an Analytical Chemistry technician at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

One might say Courtney Edenfield was needled into her career path as a teen.

“I was going to go into medicine, but I have a huge fear of needles,” Edenfield said. “I remember going to a doctor’s appointment with my mom. She was having fluid drawn from her knee, and I passed out — so I had to go into something else.”

Edenfield injected herself into chemistry instead. After graduating in 2020 from the University of Tennessee with a bachelor’s degree in interdisciplinary programs with a concentration in neuroscience, she joined Analytical Chemistry Mission Operations as a technician in the radiochemistry lab at Y-12. Edenfield manages the sample flow and performs a wide spectrum of analysis, which supports a number of Y-12 programs.

“I really like it,” she said. “It can be really challenging working with all the different chemicals. You have to be super accurate.”

In the job, “I get samples and prepare them using several different procedures,” Edenfield said. “They’re analyzed on specialized instrumentation. We examine uranium and look for transuranic activity, which is basically the presence of isotopes that have a higher atomic number than uranium.” This includes elements such as neptunium, plutonium, and americium.

Working at Y-12 and supporting its mission runs in Edenfield’s family. Her father, Tommy Keylon, has been with the company 44 years. He is a tube assembler and makes filaments that are used on the instruments in the isotopic lab, just a few doors down from his daughter’s lab.

“I get to walk up and down the same hallways that he has been walking since before I was born,” Edenfield said. Her grandfather, Gordon Sutton, also worked at Y-12 during his career, which was mostly spent at K-25 in the barrier manufacturing plant as a production control manager.

When Edenfield isn’t in the lab, she analyzes fashionable looks in the Pop of Color Closet, her 4-year-old online consignment clothing store she started while attending UT.

“I love fashion and all the fun girly things,” she said. “The store has a lot of bright clothes, like Lilly Pulitzer pieces. I have many out-of-state customers from places like South Carolina and Florida. It’s really busy from January to August. This time of the year, people are preparing their spring and summer wardrobes.”

Although the store consumes much of Edenfield’s spare time, she enjoys it and has designs to expand.

“It’s turned out to be a pretty cool side business,” she said. “I would love to make it a full-on boutique, still online, but with a larger presence.”

As an employee, how do you want to be remembered?

I hope people would remember me as someone who was very approachable, someone they could talk to or ask a question. Even if I sometimes didn’t know the answer, I would help them find it.

What is your favorite aspect about your work environment? How does that aspect make you know the mission is being met?

It would have to be the teamwork culture. We have a great team and work really well together. This allows us to be successful. We all have our responsibilities, and we hold each other accountable. We get the job done and help the customers meet the mission.

What advice would you give someone who is new to Pantex or Y-12?

Take in all of the experiences that you are given and capitalize on any opportunity that comes your way. Be ready to work hard and be open to try new things, and you will go far.

What’s your top bucket list item and why?

My husband and I have always wanted to go to Europe on a 2- or 3-week trip. France, Italy, and Greece are on the top of the list of the places we want to visit. This would be amazing, since I have never been out of the country.

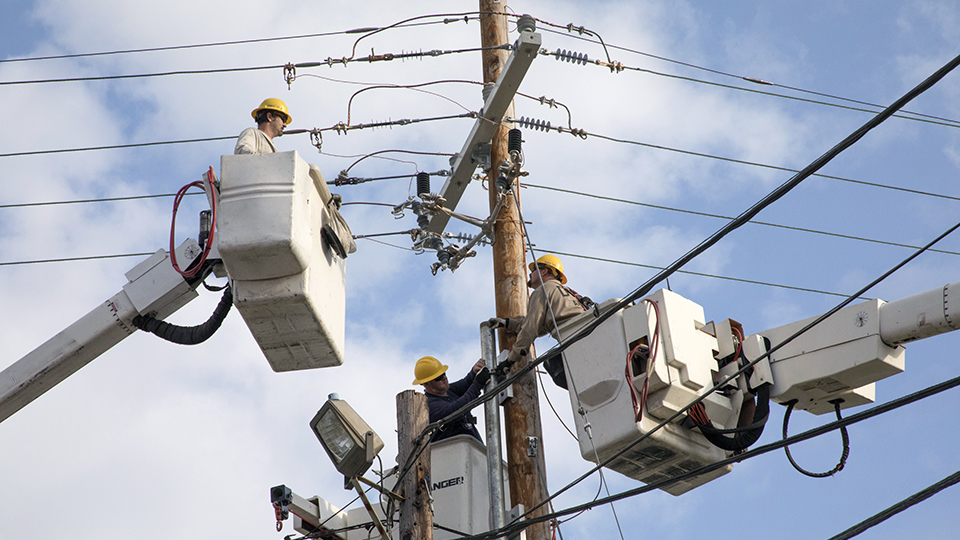

Utilities technicians are part of the Y-12 Infrastructure labor force, with the majority performing hands on work.

It is safe to say that working 1 million hours without a recordable injury is a big deal, especially when an organization’s work is physical and happens “in the elements.”

Y 12 Infrastructure achieved this during a recent 6 month span. The organization has six departments with 1,200 employees, with more than 60% of them performing hands on work daily. Departments include Waste Management, Utilities Management, Asset Management and Reliability Execution, Facilities and Sustainability, Plant Services, and Mission Systems and Integration. The organization executes 2.2 million work hours annually.

“When you look at all of the hands-on work we do, that’s why this is such a significant accomplishment,” said Y-12 Infrastructure Senior Director Andy Huff. “There are many opportunities to be in harm’s way or in a high risk situation. We work in every production facility and all over the Y-12 site.”

One of the ways Infrastructure has gotten ahead of injuries is to routinely evaluate equipment used to do work around the site.

“We regularly have events during the year when vendors bring in new equipment,” Huff said. “It’s important to make sure our tools and equipment are in good condition. If something isn’t, replace it.” Also part of the safety success story are crew briefings that emphasize looking out for coworkers, the stop or pause work philosophy, and exercising a questioning attitude.

When a college or professional sports team wins a championship, usually there is a celebration with much fanfare to commemorate the feat. Huff chose a different way to mark the milestone.

“I didn’t want to treat it like we have arrived at a destination. Being safe is part of what we have to do. I want to celebrate every day that we helped prevent someone from getting injured.”