YPH-22-999139

Process Support Facilities Sheetrock Installation

Process Support Facilities Sheetrock Installation

UPF Construction Site—early-January 2022

Personnel Support Building Progress—late-December 2021

UPF construction site—late-December 2021

Work on the Fire Tank Pump House roof beams

Mechanical Electrical Building Electrical Inspection

Pipefitters Installing Breathing Air System Piping in the Process Support Facilities Process Support Equipment Room

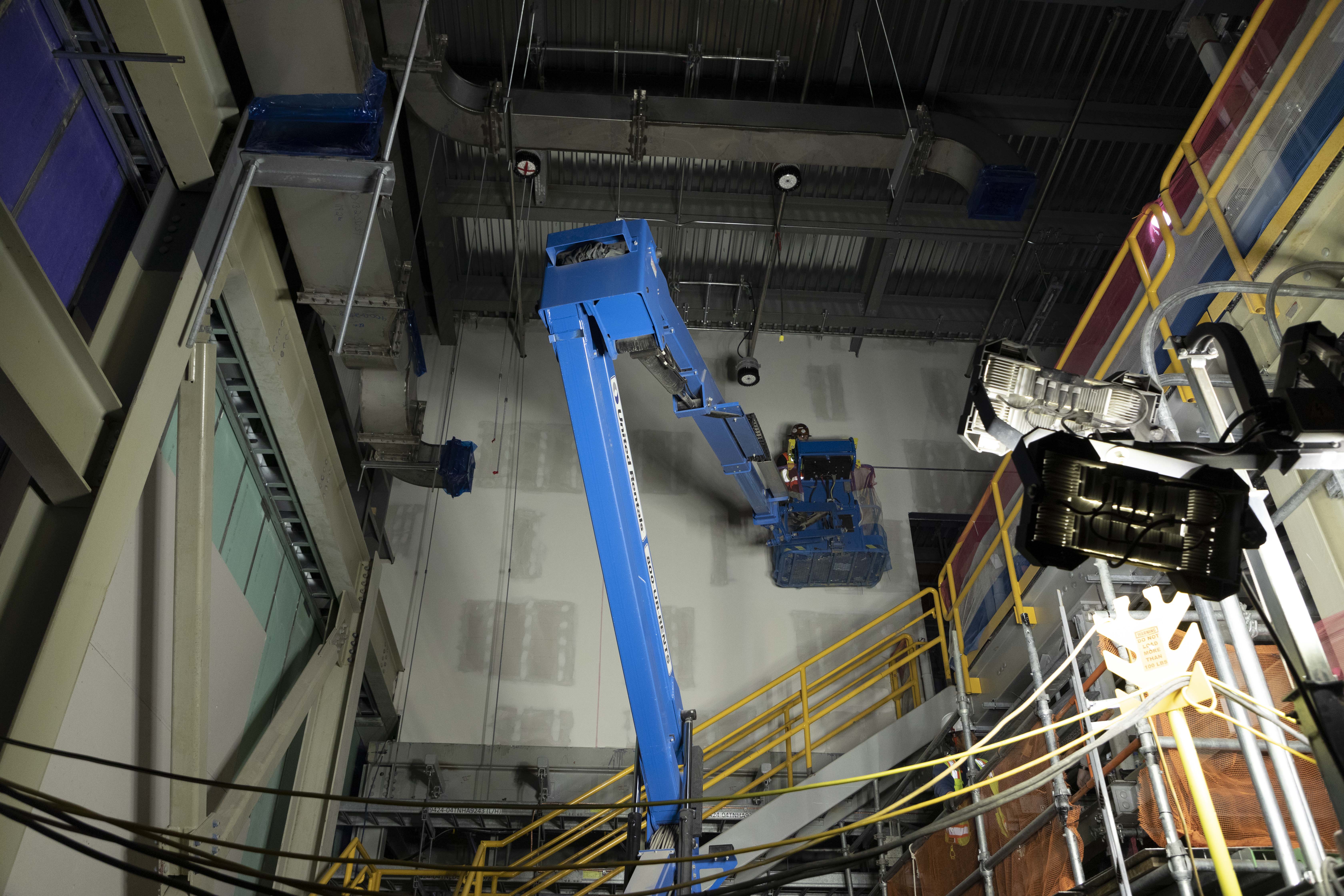

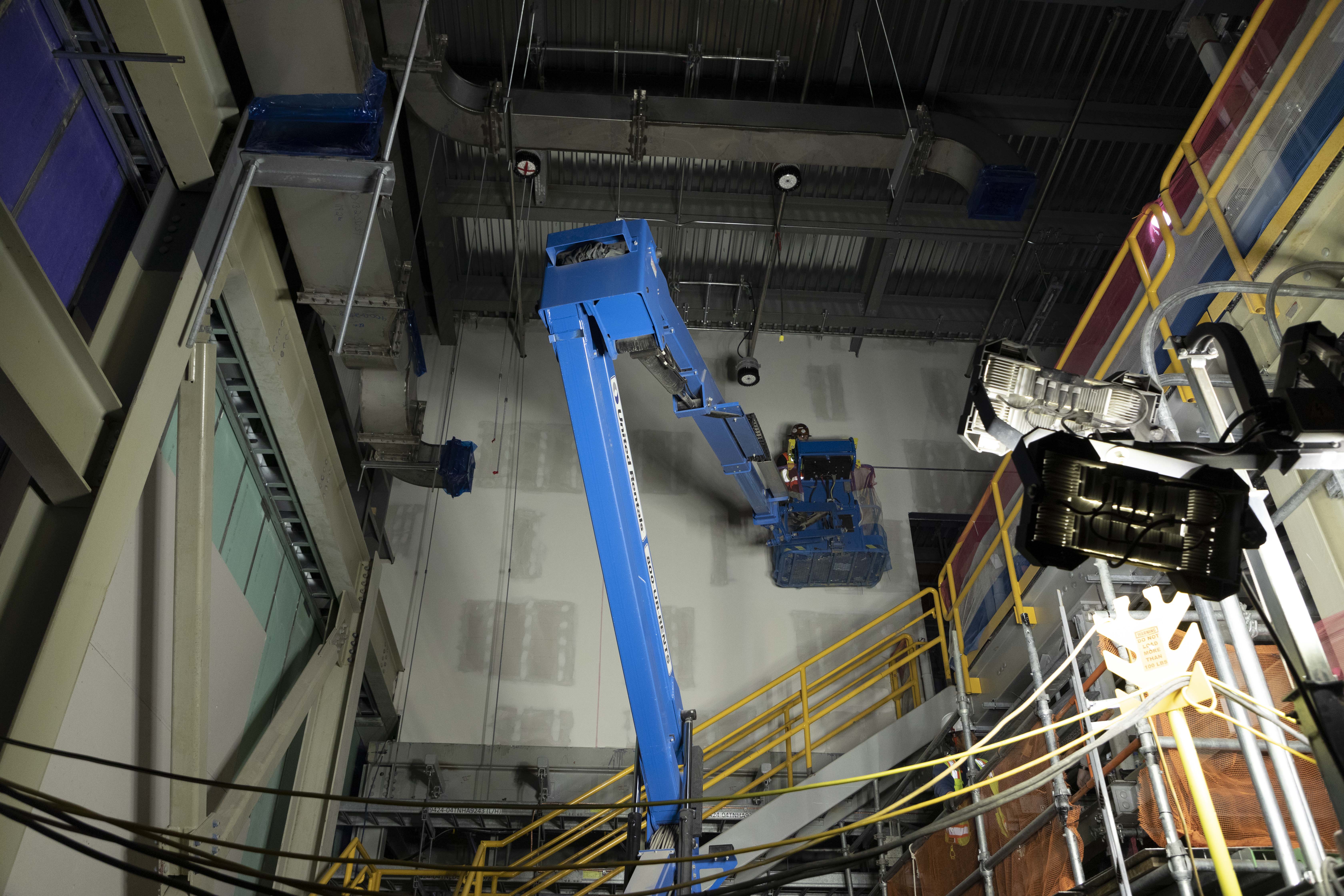

Main Process Building Ironworkers welding an HVAC louver

Eight vaporizers at the Process Support Facilities Gas Yard—Process Gas Yard deliveries are complete

Construction on the UPF Fire Tank Pumphouse is underway