Uranium Processing Facility

3:56 min.

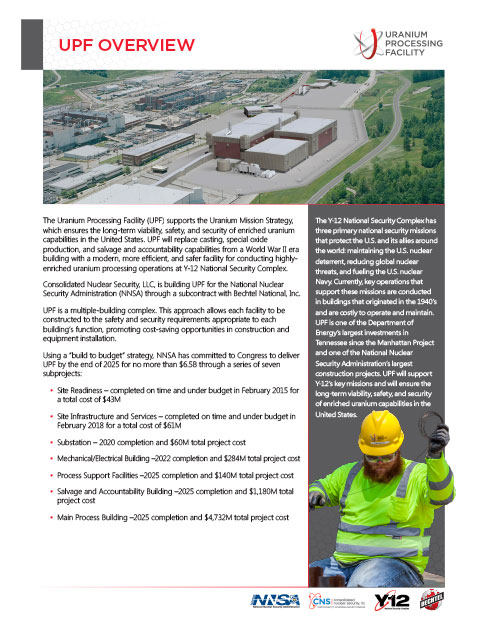

Learn about Y-12’s new story: the Uranium Processing Facility, one of the largest construction projects in Tennessee history. UPF is an essential part of the National Nuclear Security Administration’s modernization efforts.

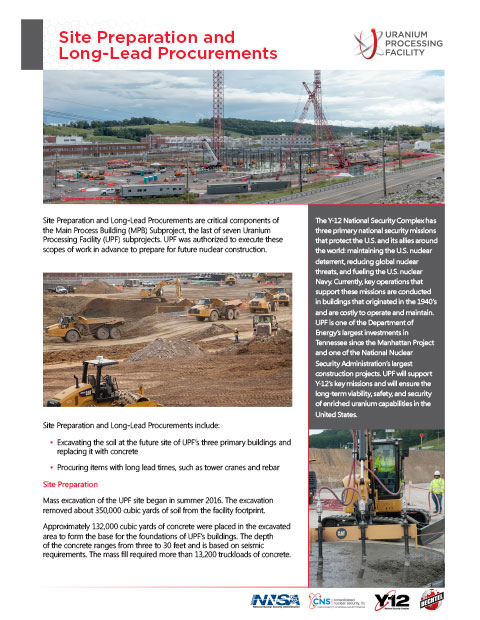

The National Nuclear Security Administration is constructing a modern Uranium Processing Facility (UPF) to support key missions of the Y-12 National Security Complex and ensure the long-term viability, safety and security of enriched uranium capabilities in the United States. UPF will provide new floor space and consist of processing capabilities for enriched uranium casting, oxide production, and salvage and accountability operations to support the Nation’s nuclear weapons stockpile, defense nuclear nonproliferation, and naval reactors.

The multiple facility complex allows each building to be constructed to the safety and security requirements appropriate for the building’s function, providing cost-saving opportunities in both building construction and equipment installation.

Using a “build-to-budget” strategy, NNSA has committed to Congress to provide these facilities in order to phase out mission dependency on Building 9212. UPF will be built through a series of seven subprojects:

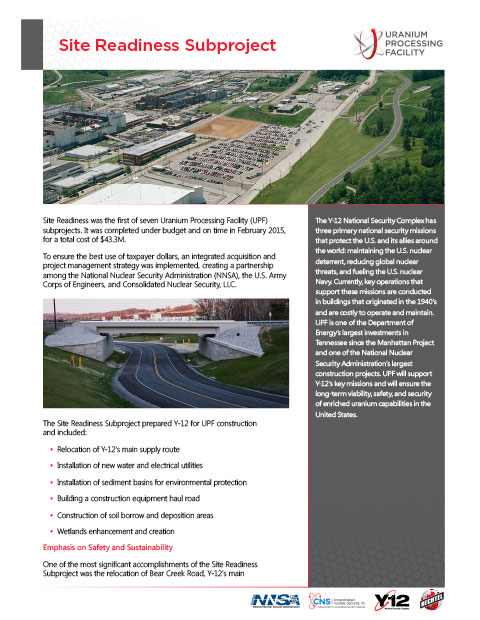

- Site Readiness – completed on time and under budget

- Site Infrastructure and Services – completed on time and under budget

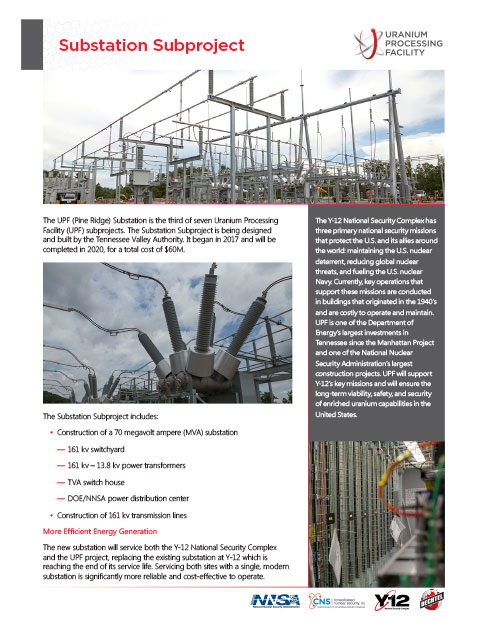

- Substation – completed ahead of schedule and under budget

- Mechanical/Electrical Building – completed

- Process Support Facilities – underway

- Salvage and Accountability Building – underway

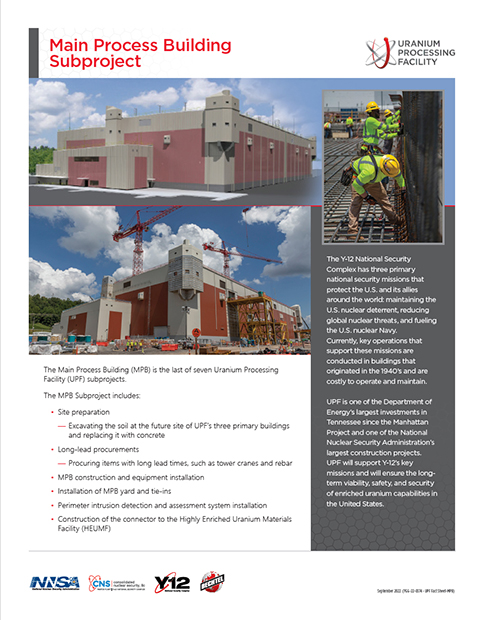

- Main Process Building – underway

The new facility will improve worker safety, reduce operational costs and energy consumption and allow more efficient mission delivery.

One of the largest construction projects ever built in Tennessee, at the height of construction UPF will employ approximately 2,000 people.