yph-19-837992

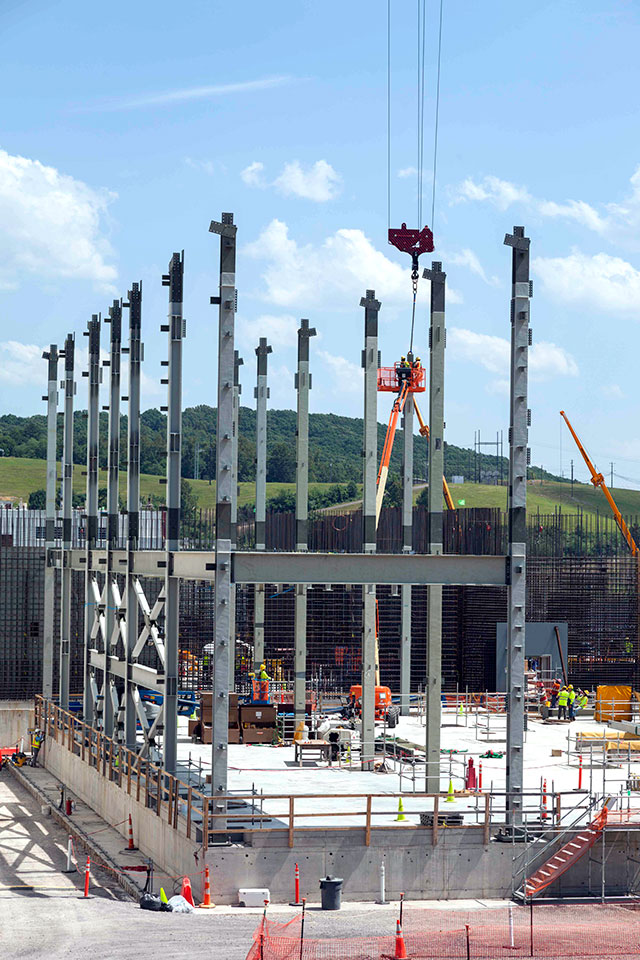

Construction is almost complete on the Offsite Fabrication Facility located at the East TN Technology Park. This 100,000-square-foot facility will serve as the primary fabrication area during the construction of the Uranium Processing Facility.