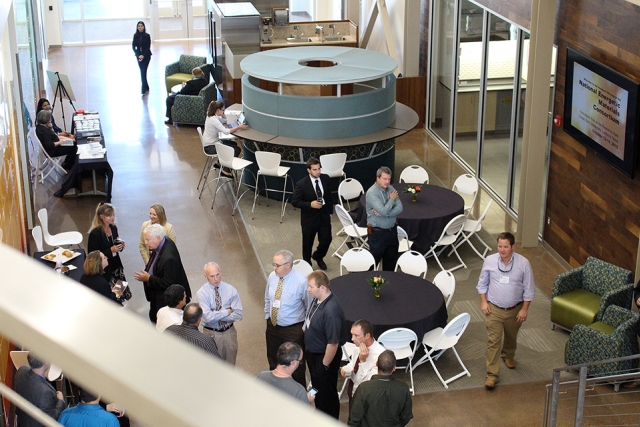

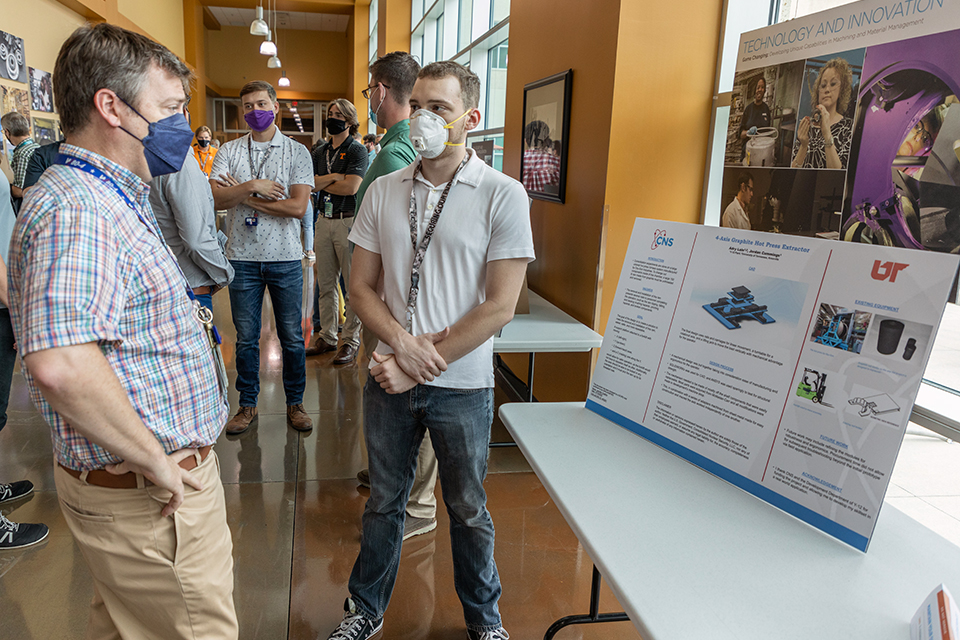

Y-12 recently hosted the Nuclear Innovation in Tennessee Expo to enhance collaborations with universities in Tennessee. Photo by Brian Holt.

It may have started in the morning, but a number of Y-12 employees and potential university partners showed up at NITE in New Hope Center.

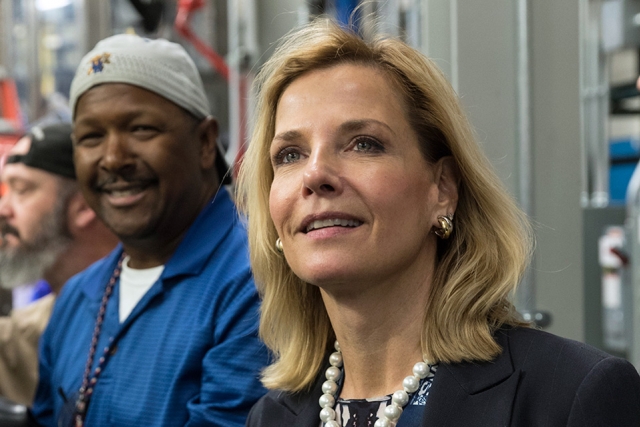

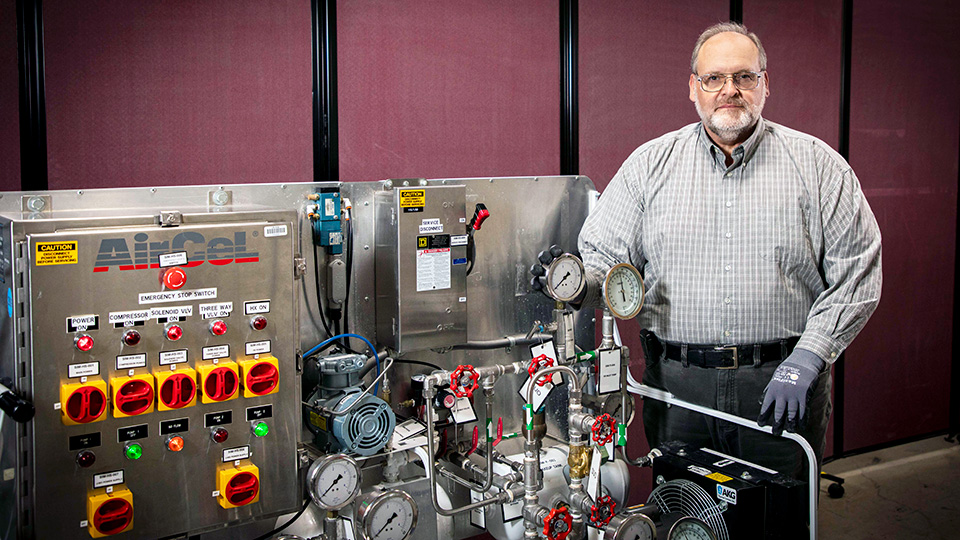

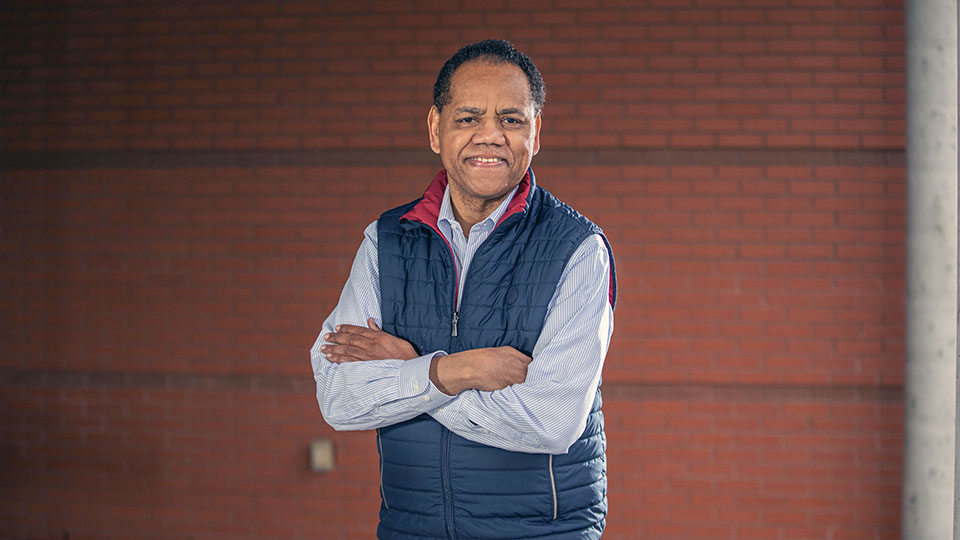

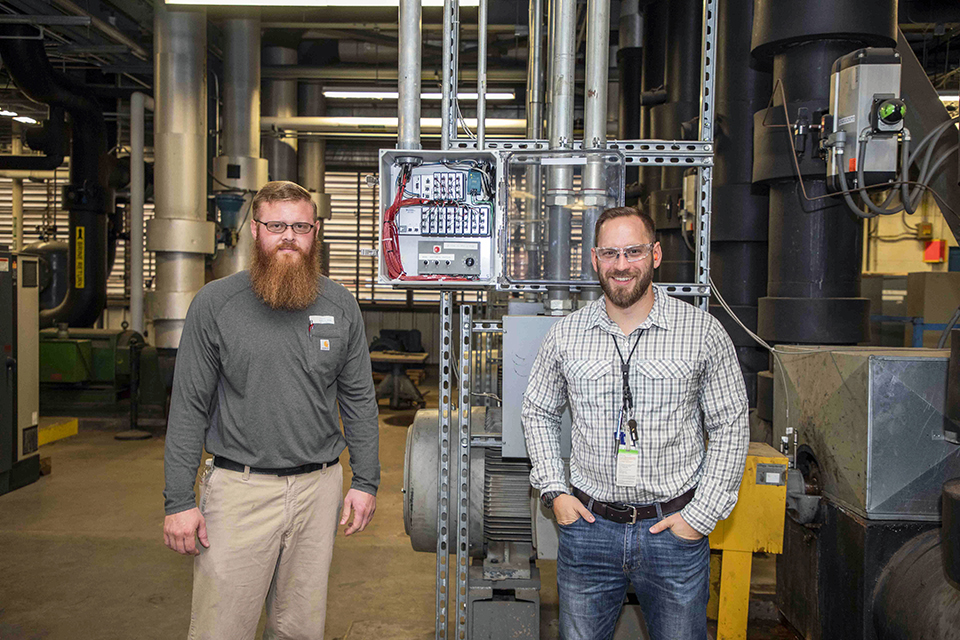

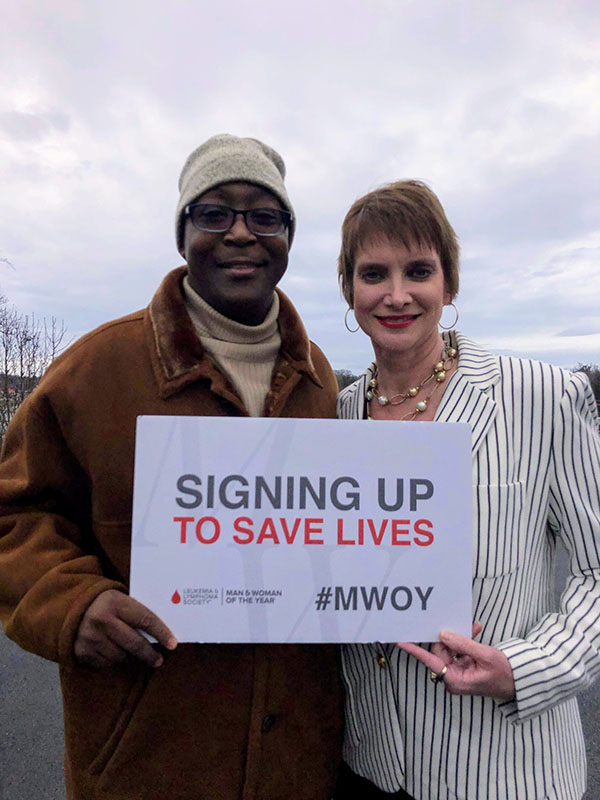

Nate S. of Lawler-Wood Y-12 and Jan West, deputy manager of Production and Operations, take a moment to exchange cost-free kindness. Nate has been working in Oak Ridge for 35 years, and he says he has enjoyed every day of it.

Nate S. of Lawler-Wood Y-12 and Jan West, deputy manager of Production and Operations, take a moment to exchange cost-free kindness. Nate has been working in Oak Ridge for 35 years, and he says he has enjoyed every day of it.

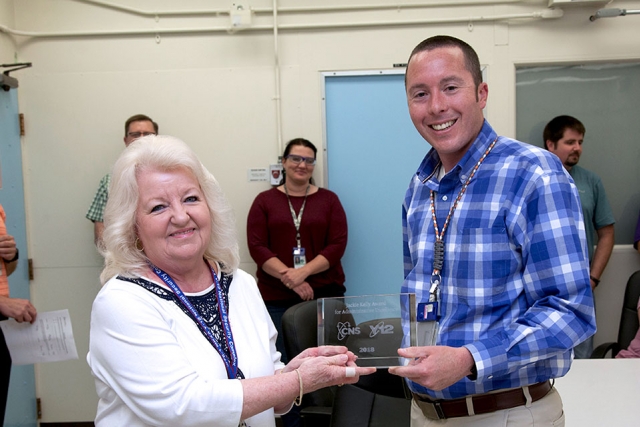

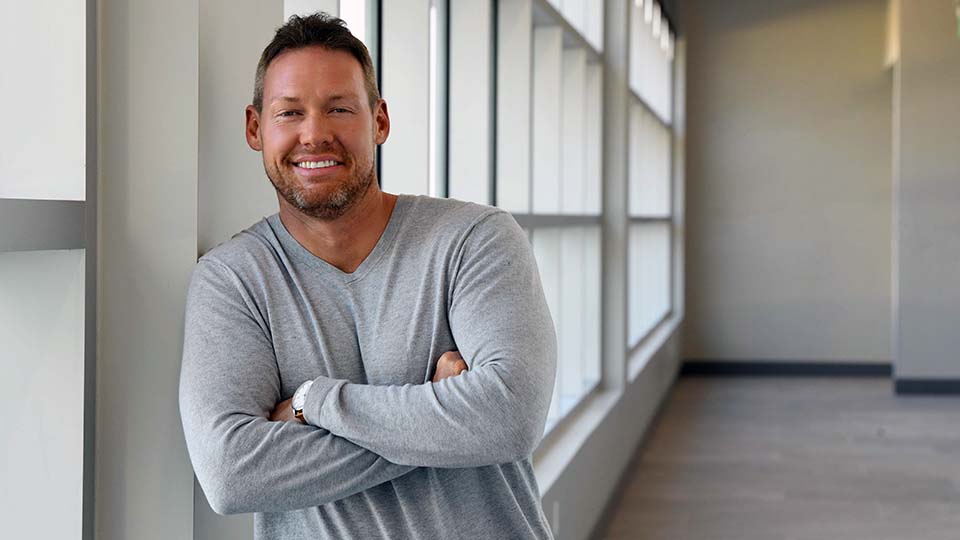

Josie Fellers

Josie Fellers

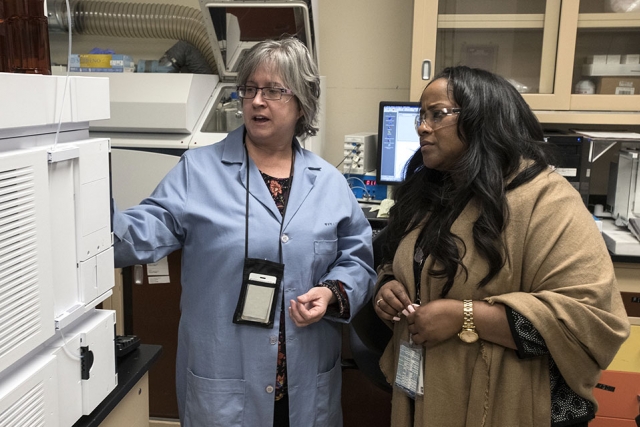

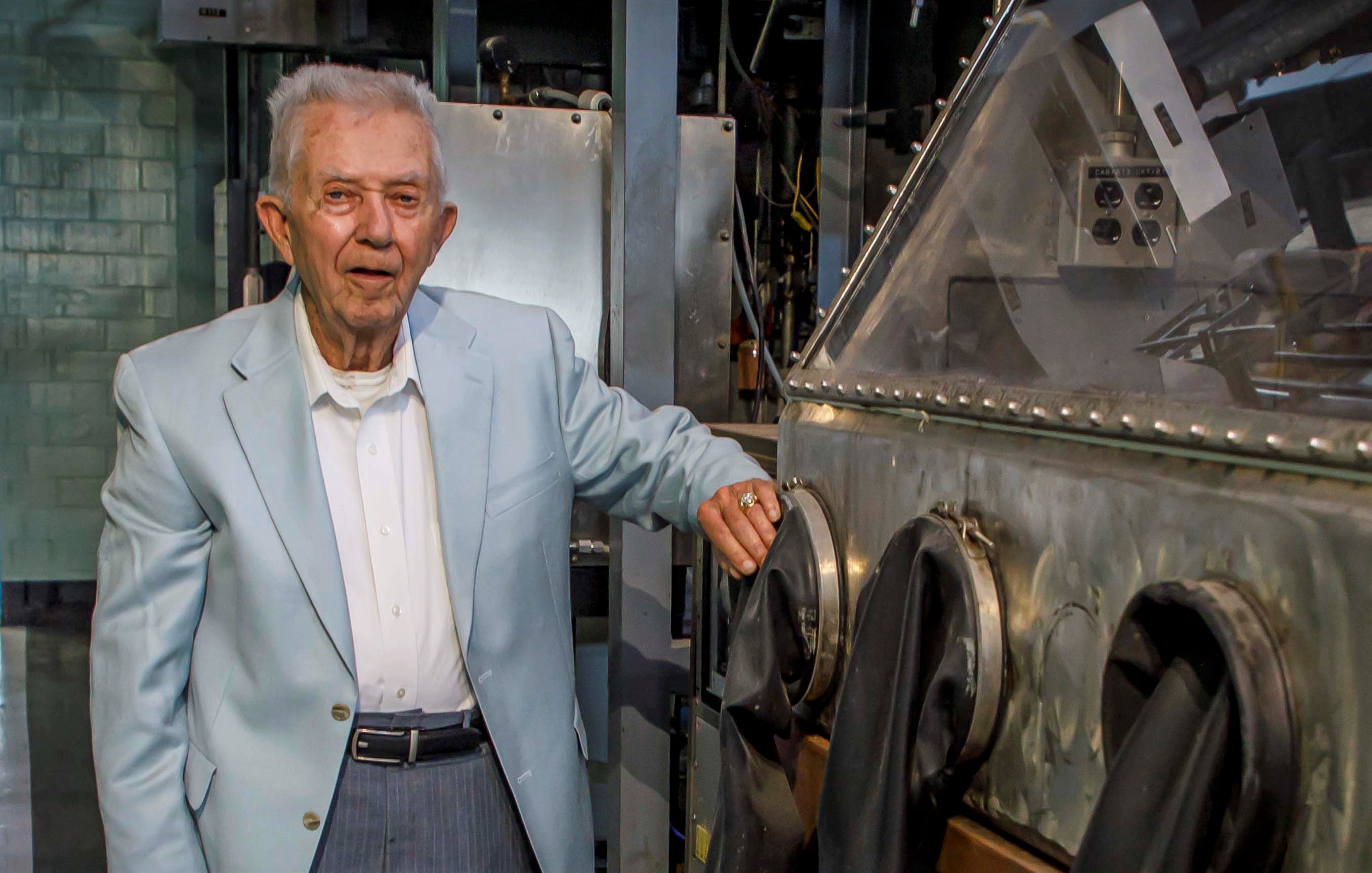

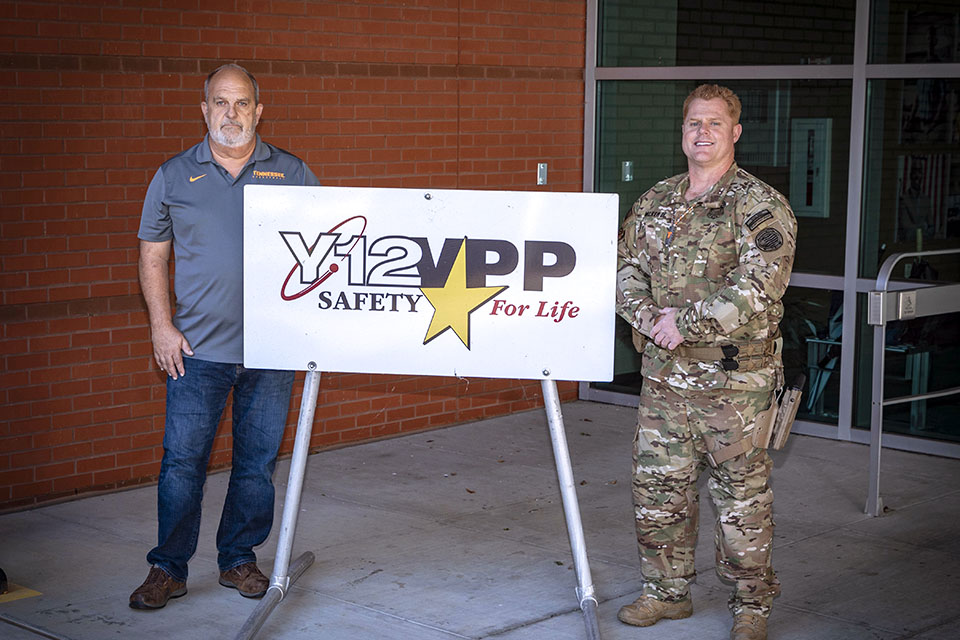

Y-12 employees Tony and Barbie White

Y-12 employees Tony and Barbie White

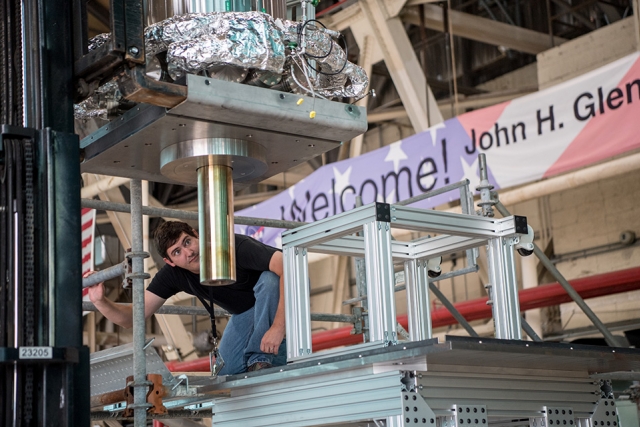

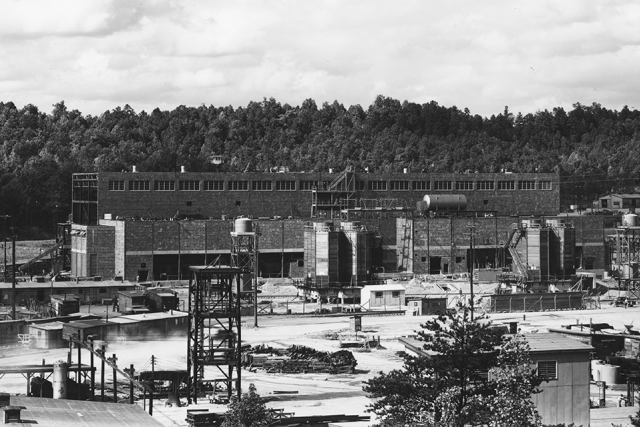

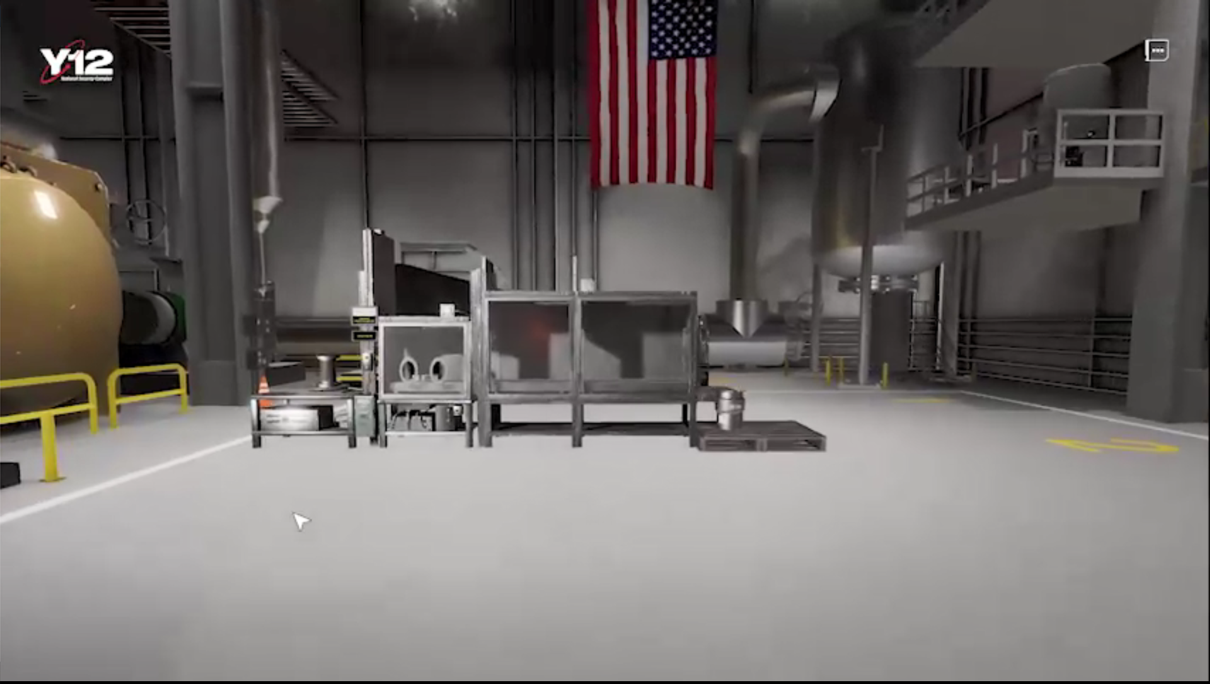

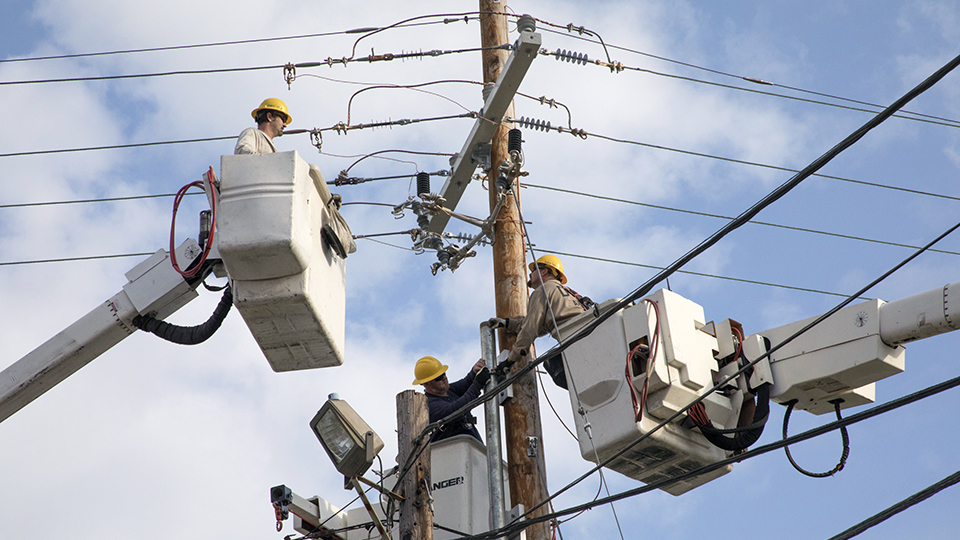

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months.

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months.