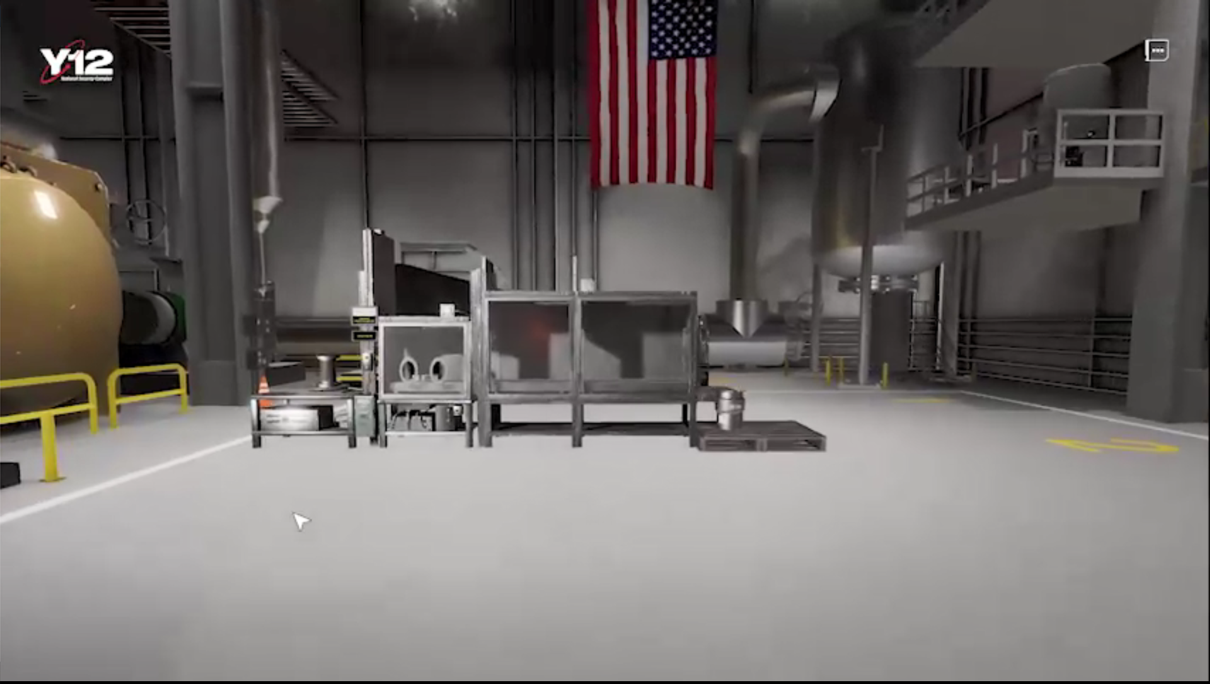

A representation of a glovebox within a digital twin allows operators to practice operations virtually before working with actual materials.

It’s no secret that Y-12 works with hazardous materials in order to deliver on the site’s missions for the nation. To protect employees, the site relies on engineered controls, such as gloveboxes, and administrative requirements, including limiting exposure to a hazard. Employees receive considerable training before they work with any materials. However, there’s really no substitute for actual experience … or is there?

The answer might lie in using digital twins to simulate real-life scenarios. A digital twin is a virtual 3D model or simulation that is a replica of a real-world product, system, or process making it a valuable training tool for high-hazard, high-consequence operations.

“You can train on scenarios that you wouldn’t want to do in the real world,” said Scott Couture, senior director of Production Research, Development and Integration. “For example, you can simulate a part breaking during microwave casting. That’s something you wouldn’t want to create in a real-world environment.”

Training first responders

At the Emergency Response Training Facility on the Oak Ridge Enhanced Technology and Training (ORETTC) campus, Director Ashley Stowe said they are now able to train first responders in a different way than before by using a virtual 3D space.

“ORETTC is using virtual reality as a more cost-effective training method for the Office of Radiological Security,” continued Stowe. “Rather than flying everyone here to train, we can now ship headsets out and bring them together in the virtual environment.”

Projecting future-state operations

Fabrication has been using a digital twin to design the Advanced Manufacturing Prototype Shop. The team had a conceptual layout in a drawing that changed many times. When they examined the space in VR, they realized the layout was not the most efficient. Now they are developing the layout in VR to give Design Engineering a place to start.

Couture said a digital twin can create an accurate and in-depth virtual representation of systems. “You can put physics behind it with process flow and capacity analysis—things that increase efficiency and reduce cost.”

The team’s experience illustrates the ease of taking a vision and making it some form of reality.

There are other advantages to using a digital twin, including demonstrating future capabilities. When new or greater work scopes are planned, a virtual tour of the future scope can be created.

Enhancing safety at UPF

Don Sproul, CNS Environment, Safety, and Health manager for the Uranium Processing Facility (UPF) Project, recognizes that while his applied-use case for a digital twin may not be as the technology was originally intended, it has been extremely effective during the construction phase of the project. The UPF leadership team has engaged with ORETTC to develop a solution to better communicate incidents and lessons learned, along with putting today’s workforce in tomorrow’s work environments.

Stowe said the technology has that “wow” factor. “When you show how it can be used, people really get excited. For UPF, they are able to walk into spaces that aren’t built yet,” he said. “The digital twin speeds up transition/commissioning time and our understanding and validation of the equipment. Employees can learn faster and test against abnormal conditions or in different configurations. These activities are mental studies now, but we can leverage the system to actually see it.”

The simulations have been well-received by the UPF Project workforce. “Many of our employees are gamers, so they are familiar with this type of presentation,” said Sproul.

Given the reception and effectiveness of these digital twins, Sproul can see the tool being used for a number of things. “I’d like to use the technology for the mobile equipment and personnel interface so employees can explore the setting and how the work feels without exposing themselves to hazards of moving construction equipment,” he said.

|

Level 1, Virtual Twin: a physically accurate digital representation Level 2, Connected Twin: integrates real-time data to provide performance insight Level 3, Predictive Twin: leverages data to predict outcomes Level 4, Prescriptive Twin: leverages modeling and real-time simulation for future scenarios Level 5, Autonomous Twin: uses multiple real-time data feeds to learn and make decisions to correct issues automatically |

Future is virtual

Plant-Directed Research and Development is developing digital twins at various scales, and the investment is also helping to create tools for other projects. “Digital twins are tools. They are a simulation at some level to help you solve some problem, such as improving the capacity and reliability of a machine,” said Couture.

While a “true” digital twin is a simulator, Stowe noted that not all projects need the full simulator because different projects require different levels of connectivity and realism.

“There are applications across the maturation continuum (see sidebar),” Stowe said. This continuum allows digital twin technology to be beneficial across a variety of projects with differing needs.

“Digital twin technology really has something for everyone—engineers, data scientists, procedure writers,” said Stowe. “The technology applies to and can inform many, many jobs and facilitate decision making.”