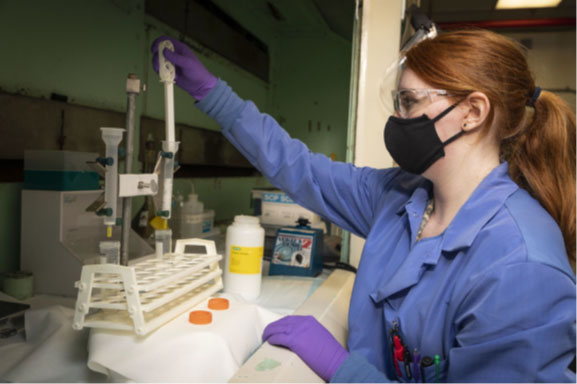

Development’s Trevor Roberts, Direct Material Manufacturing lead, isolates several key samples to be sent to Y-12’s Analytical Chemistry Organization.

The National Nuclear Security Administration’s (NNSA’s) Office of Defense Nuclear Nonproliferation (DNN) works globally to prevent state and non-state actors from developing nuclear weapons or acquiring weapons-usable nuclear or radiological materials, equipment, technology, and expertise. Through the Office of DNN Research and Development (DNN R&D), NNSA advances its nuclear threat reduction mission by developing ways to detect and monitor foreign nuclear fuel cycle and weapons development activities.

This summer Development, the Analytical Chemistry Organization, Program Integration, Mission Engineering, and Environment, Safety, and Health leveraged ongoing Direct Material Manufacturing and completed the second campaign in isolating select lithium samples.

Consolidated Nuclear Security (CNS) Chief Scientist Greg Schaaff said, “When people think of nuclear nonproliferation and forensics, most think of the production and use of uranium and plutonium materials. However, the production of lithium compounds are central to civilian energy and military applications.”

Matthew W. Francis is the Pantex and Y-12 contact with DNN R&D. He said, “Using Y-12’s lithium processing and applications core capabilities, DNN R&D has funded a collaboration between CNS, Lawrence Livermore National Laboratory, and Los Alamos National Laboratory to determine potential signatures capable of differentiating between civilian and weapon applications of lithium compounds.”

“In our initial subsampling campaign in FY19, we had to overcome many challenges along the way,” said Jason McCall, program manager of Global Security and Strategic Partnership Programs. “Challenges included failed coring tools, answering questions on contamination, and coordinating with other projects in regards to schedule and priority. Trevor Roberts was essential in getting us through these challenges, as well as many others. By the time we started ramping up the second subsampling campaign in FY20, our initial challenges were a distant memory. Trevor and the entire Direct Material Manufacturing team were key in making our subsampling campaign a success.”

Following the subsampling efforts (which is when a sample is drawn from a larger sample), several lithium samples were shipped to ACO to run through several measurement methods to identify a variety of trace elements.

“ACO sees many new matrices that push our current analytical capabilities,” Tom Oatts, ACO lab supervisor, said. “Through the use of innovative approaches to existing lab methods, Sarah Slack and other ACO team members can push these capabilities to meet our customers’ needs and requirements.”

Francis said, “While this project is still ongoing, accomplishing these campaigns was essential for the overall success of the project. This effort could not have been executed if it wasn’t for the great collaboration across the various Y-12 organizations.”

Sarah Slack of the Analytical Chemistry Organization separates key trace elements that potentially could be used for differentiating between interdicted lithium samples.