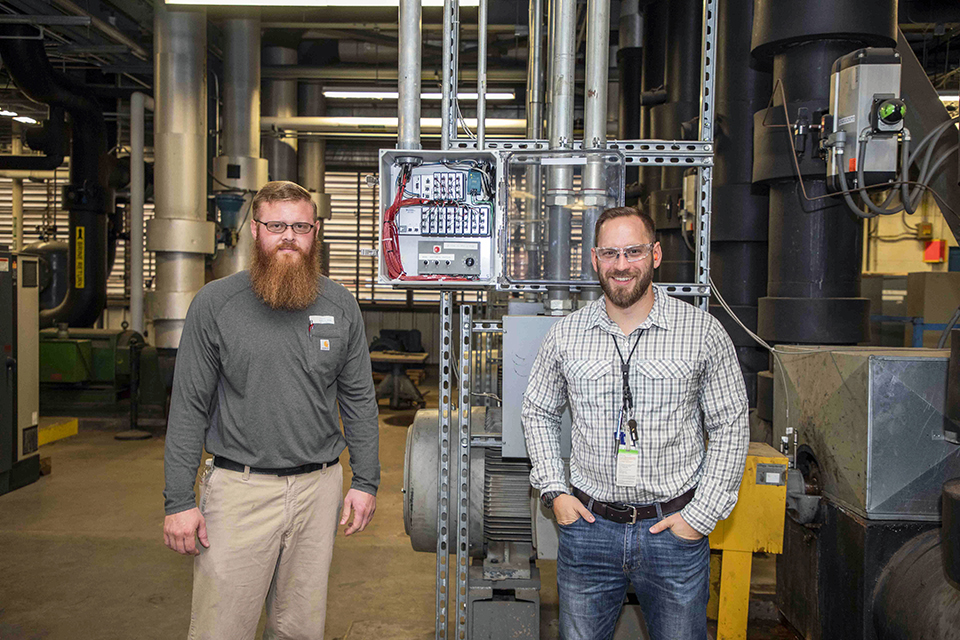

Ronald Bolden Jr. (left) and Luke Birt, pause for a photo with Building 9767-13’s installation

Technology is integrated throughout the modern business world and at the heart of Consolidated Nuclear Security’s digital transformation. It is often the common source credited to improving the quality of processes and systems in our lives. Whether it’s the ability to rapidly gather information from a search engine or track physical performance with a smart watch, many of us can identify how technology simply makes our lives easier and more informed.

With remote tracking and wireless data collection capabilities now also playing a critical role for our people, processes, and systems at Pantex and Y 12, our digital transformation is advancing the modernization of site operations.

“Our team dreamt of digital transformation to support the CNS Strategic Plan,” said Travis Childress, condition based maintenance (CBM) lead engineer. “Specifically, we sought to improve the reliability and availability of aging infrastructure through remote and real-time CBM monitoring.”

By definition, CBM is a monitoring strategy that observes the present condition of an asset or machine to determine what maintenance should be done based on signs of decreased performance or indication of failure.

While the CBM process isn’t new to CNS, the ability to continuously and remotely track a machine in the field using the CBM strategy is transformational.

“Previously, data collection activities required an analyst or craftsperson to physically collect the data in the field. The analyst reviews the data for early detection of failure modes and communicates concerns before equipment reliability is impacted,” said Childress.

Recently, the CBM team began real time machine health monitoring at Y-12, known as the Enterprise Operational Monitoring System. Now, more than 10,000 measurement points can be collected in three second measurement intervals, for analysis using the EOMS dashboard. The result is a robust graphical indication of machine health used to immediately identify the root causes of machine failure and prevent unplanned maintenance. Over time, data trending and patterns can be analyzed to better predict machine maintenance needs and further limit machine downtime.

“The EOMS project is a huge accomplishment for the Digital Transformation program,” said Jerry Stanley, lead for Digital Transformation. “By laying out real time monitoring solutions for CBM, we’re not only modernizing the state of our tracking and sensor operations, but supporting our mission long term with technology that’s industry standard.”