Y-12 Blog

Director of Assembly/Disassembly Operations Abe Mathews (left) gives the USS Tennessee sailors a behind the scenes look at Y-12.

Director of Assembly/Disassembly Operations Abe Mathews (left) gives the USS Tennessee sailors a behind the scenes look at Y-12.

When the USS Tennessee patrols the world’s oceans, stealthily submerged to depths unknown, the Ohio Class ballistic missile submarine is capable of carrying a payload of Trident II missiles tipped with W76 or W88 warheads.

The crewmembers — and the nation — have come to accept the steadfast reliability of those warheads that are produced as a result of work at Y-12, Pantex and elsewhere across the Nuclear Security Enterprise, but during a recent visit to Oak Ridge, five USS Tennessee sailors got a first hand look at exactly what goes into ensuring the safety, security and effectiveness of the nation’s nuclear arsenal.

“It gave us an appreciation of the infrastructure that is there to enable this capability for us to go out and perform our mission,” said the USS Tennessee’s Commanding Officer Chas McLenithan.

It was the first trip to Y-12 for McLenithan and four others.

While in Knoxville for Navy Week, they made a special visit to Oak Ridge National Laboratory and Y-12, touring a production facility and the Highly Enriched Uranium Materials Facility. Joining McLenithan was Lt. Colin Williams, the submarine’s assistant weapons officer, as well as Master Chief Stacy R. Hammann, First Class Petty Officer Bryan Lynch and Second Class Petty Officer Merlin Hyland.

During the tour, they were briefed on assembly and disassembly operations at Y-12 and saw where the nation’s highly enriched uranium is stored. With the importance of the nuclear deterrent as significant as it was decades ago, they emerged with a message that reinforced the credibility of U.S. nuclear arsenal.

“It definitely gave me a newfound appreciation for this part of the mission,” Williams said. “You do the same processes day in and day out, but you see all these patriotic people doing their job and doing it well. Everyone was very energetic and so enthused about what they did, explaining their processes to us as the end user. It was a great experience to talk to them and to say you guys make a great product. We know we can always count on them.”

Williams added, “What we saw was pretty amazing stuff, stuff you don’t get to see in your everyday job. Us being the end user, it definitely stood out in my mind.”

Their submarine may bear the name Tennessee, but what was tucked in the hills of Oak Ridge was still a revelation.

“The amount of generations that have built up the capability they have there, the initial developers and the maintainers now, and the technical ability that goes into that and is still invested in keeping us able to do our mission was a real eye opener,” McLenithan said.

Pantex’s Darla Fish greets an Ascension Academy student as teams check in for the National Science Bowl® at the National 4-H Youth Conference Center in Maryland.

Pantex’s Darla Fish greets an Ascension Academy student as teams check in for the National Science Bowl® at the National 4-H Youth Conference Center in Maryland.

Our nation’s capital recently played host to the country’s future science and technology leaders during the U.S. Department of Energy’s 26th National Science Bowl®.

The 116 regional winning teams and their coaches, hailing from the 50 states, the District of Columbia, Puerto Rico and the U.S. Virgin Islands, assembled at the National 4-H Youth Conference Center for an action-packed five days of science activities, sightseeing and competition.

Three of the teams — Amarillo High School and Ascension Academy (middle school) from Texas and Cedar Springs Home School (high school) from Tennessee — won regional competitions sponsored by Consolidated Nuclear Security, LLC.

Learn more on the Pantex website.

The RoHAWKtics robotics team at Hardin Valley Academy, sponsored by Consolidated Nuclear Security, LLC, achieved a top 50 ranking at the FIRST® Robotics Championship in St. Louis.

The RoHAWKtics robotics team at Hardin Valley Academy, sponsored by Consolidated Nuclear Security, LLC, achieved a top 50 ranking at the FIRST® Robotics Championship in St. Louis.

Our nation’s capital recently played host to the country’s future science and technology leaders during the U.S. Department of Energy’s 26th National Science Bowl®.

The 116 regional winning teams and their coaches, hailing from the 50 states, the District of Columbia, Puerto Rico and the U.S. Virgin Islands, assembled at the National 4-H Youth Conference Center for an action-packed five days of science activities, sightseeing and competition.

Three of the teams — Amarillo High School and Ascension Academy (middle school) from Texas and Cedar Springs Home School (high school) from Tennessee — won regional competitions sponsored by Consolidated Nuclear Security, LLC.

Learn more on the Pantex website.

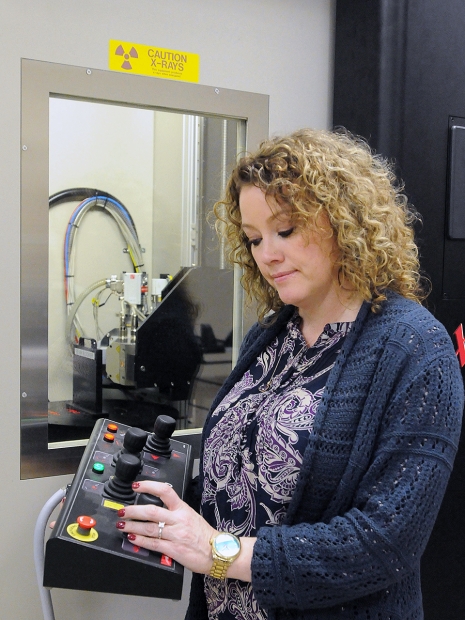

Pantex’s Felicia Bellis uses controls to move a turntable of the microfocus X-ray machine, one of many technologies Pantex technicians use to ensure quality.

Pantex’s Felicia Bellis uses controls to move a turntable of the microfocus X-ray machine, one of many technologies Pantex technicians use to ensure quality.

Pantex and Y 12 are hotbeds for the advancement of science and technology. The scope of our research and development has widened from a single focus World War II defense mission to a plethora of capabilities to address today’s nuclear security challenges.

Y-12 recently developed a high-efficiency thermal neutron detector. The detector is a single-crystalline device that could be used in handheld nuclear nonproliferation and homeland security applications to locate fissile materials. This solid-state neutron detector offers the significant advantages of portability, sensitivity, simplicity and low cost.

Pantex is home to the world’s only X-ray inspection system, known as CoLOSSIS, for nuclear weapon components. At approximately 32,000 pounds, the lead-shielded CoLOSSIS is nearly 100 times more powerful than medical computed tomography, or a CAT scan.

Visit the Pantex and Y-12 websites to learn about these and other research capabilities and technologies.

Y-12 Site Manager Bill Tindal (left) and NPO Manager Geoff Beausoleil (right) congratulate electrician graduate Andre Blocker on successful completion of the Y-12 Apprentice Program.

Y-12 Site Manager Bill Tindal (left) and NPO Manager Geoff Beausoleil (right) congratulate electrician graduate Andre Blocker on successful completion of the Y-12 Apprentice Program.

Consolidated Nuclear Security, LLC recently celebrated the graduation of 14 new journey workers from the Y‑12 Apprentice Program. The seven electricians, three pipefitters, three stationary engineers and one carpenter recognized in mid‑April marked a total of 71 graduates since the program was reinstated in 2008.

The Apprentice Program, which is registered with the U.S. Department of Labor and the U.S. Department of Veterans Affairs, is a unique partnership between CNS and the Atomic Trades and Labor Council, an umbrella organization representing some 1,100 Y‑12 workers under 13 international unions. Its combination of classroom and shop-floor education trains workers to union specifications for journey worker status.

“The certificate you are about to receive is something to be proud of,” ACR Chief Steward Tim Milligan told the graduates. “This is a great accomplishment for you, CNS and our union.”

Depending on their trade, apprentices complete between 6,400 and 8,000 hours of full-time on-the-job learning. In addition, apprentices spend between 575 and 1,250 hours in the classroom, often giving up their evenings to learn from certified union instructors.

“I came into the program with very little experience in the electrical field, but graduated feeling confident in my skills as an electrician,” said graduate Matthew Hensley, who became the third member of his family to graduate from the Y‑12 Apprentice Program as an electrician. His mother and uncle completed an earlier iteration of the program in the 1980s.

Despite the lengthy process and extensive hours, Hensley wouldn’t hesitate to do it all over again. “It is something that will stay with me for the rest of my life and give me opportunities that I never would have had before,” said Hensley, who is now assigned as a maintenance electrician to Development’s buildings.

For all its benefits to each individual participant, the Apprentice Program also provides Y‑12 with a pipeline of skilled workers to support the site’s important national security missions.

“This program has positioned Y‑12 for the long term at a time when skilled craft workers are in high demand,” Milligan said. “It’s a great way to transfer knowledge from highly skilled workers to the new workforce, guaranteeing we’ll be able to meet our future production goals.”

The 2016 graduation included the first‑ever class of stationary engineers, better known at Y‑12 as utility operators. They operate all the sanitary water, sewer, cooling and heating systems throughout the site, including humidity and air control in mission-critical production facilities.

Retired chief steward Kevin Ringley, who helped initiate the stationary engineer program in 2011, attended the April ceremony to see the first class graduate. “I had a great sense of accomplishment for them,” Ringley said. “They were the very first stationary class to graduate at Y‑12. That’s monumental.”

Whatever the graduates’ trade, ATLC president Mike Thompson reminded them of the value — and weight — of their achievement. “The responsibility you face couldn’t be more important,” he said. “You are the ones who will take our place and carry on the proud tradition of being some of the most skilled tradesmen in the world, providing the expertise to perform the complex mission work here at Y‑12.”

ATLC president Mike Thompson welcomes Y-12’s newest journey workers.

ATLC president Mike Thompson welcomes Y-12’s newest journey workers.