Y-12 Blog

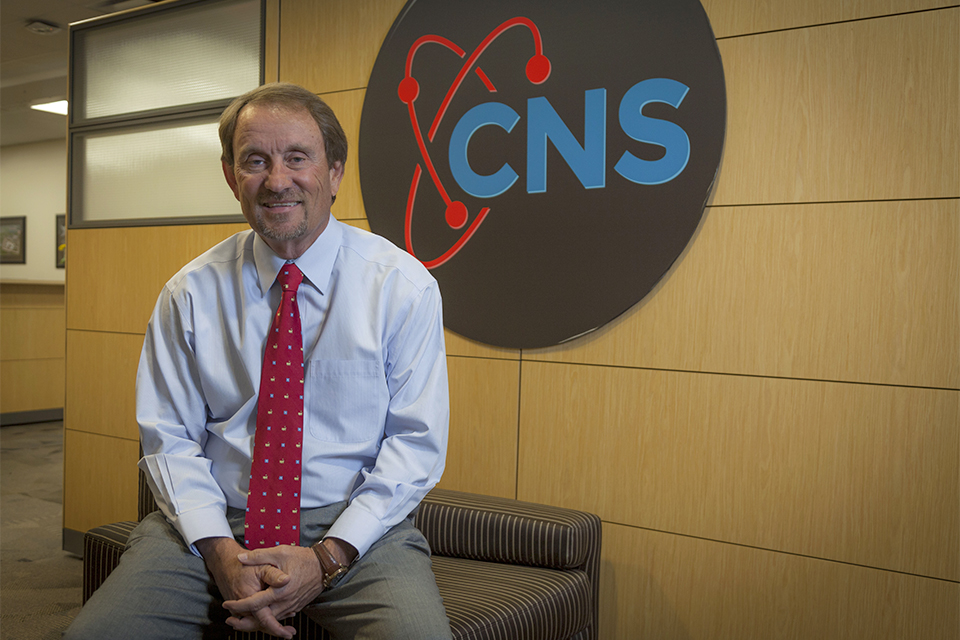

Jeff Yarbrough, Y-12 deputy site manager

Jeff Yarbrough’s expertise is rooted in ensuring the safety of our nation’s nuclear security. As Y-12 deputy site manager, it is his responsibility to provide an independent perspective in order to keep the site safe and secure from threats or abnormal conditions, including COVID-19.

Along with an integrated team, Yarbrough has served as an essential leader, after joining Y-12 only five months ago, to guarantee operations are transitioning safely and smoothly throughout the pandemic.

“The fact that we continued several mission-critical activities with a significantly reduced on site workforce and were the first site in NNSA to get a recovery plan approved are testaments to that hard work,” he said.

Before moving to East Tennessee, Yarbrough spent 29 years at Pantex where he held diverse leadership roles, implemented a new management organizational structure, and managed a portfolio of programs and projects.

“In the work that we do at Pantex and Y-12, you have to set and follow high standards,” Yarbrough said.

Over the course of his career, Yarbrough has served as a leading proponent of safety performance for the enterprise. While he was a division manager in the engineering and design division at Pantex, he played a key role in the design and implementation of a nuclear weapons process re-engineering and safety basis initiative. This initiative involved several new approaches to how nuclear assembly and disassembly work was engineered, analyzed, authorized, and performed.

“I think you have to have a vision and plan where you want change to take you,” he said. “It’s important to have a process or set of tools that you trust to help you get to that vision.”

“The recipe for success can simply be boiled down to putting the right leadership team in place, developing partnerships with internal and external stakeholders, providing the tools, and empowering the workforce to improve processes,” he said.

What does mission success mean to you, and how was it proven during the sites’ reduced mission-critical operations?

Mission success in a pandemic is new territory for all of us. You quickly realize the principles relied on for mission success, in normal times, are more important than ever in difficult and uncertain times. It was proven by a great team effort that developed and executed CNS’s pandemic prevention and recovery plans to protect our employees and ensure processes, systems, and critical plant infrastructure were maintained and available.

How did your opinion of your work environment change as CNS sites were placed in reduced mission-critical status?

Since I’ve been on site most of the time, I didn’t have to significantly change my routine like those who are teleworking, as I teleworked for only a few days during the reduced mission-critical status. For almost all of my career, face-to-face communication was the way work was accomplished, so this has been a big adjustment. I’ve been pleasantly surprised with the excellent transition to teleworking across the sites. This is a tribute to the quick technology infusion and innovation by our Information Solutions and Services teammates. I do look forward to the day when everyone returns to the site.

Are you doing what you envisioned as a young adult? If so, describe how you got here.

I grew up in a petro-chemical community. My family worked in the oil and gas industry in Texas, and I always envisioned a career in that field. However, the industry wasn’t hiring engineers after I completed my bachelor’s degree. It was a combination of circumstance and a better engineering opportunity that led me there, and I loved my time at Pantex.

Which CNS principle drives you to be successful?

Verbatim compliance is important because it ties together safety and taking care of employees. While the sites are here to support the nuclear security of the country, if we don’t support safety and compliance, then we are not successful.

What’s your top bucket list item and why?

I am an avid golfer. One day, I would love to play golf in Scotland at St. Andrews (or play at any course in Scotland!).

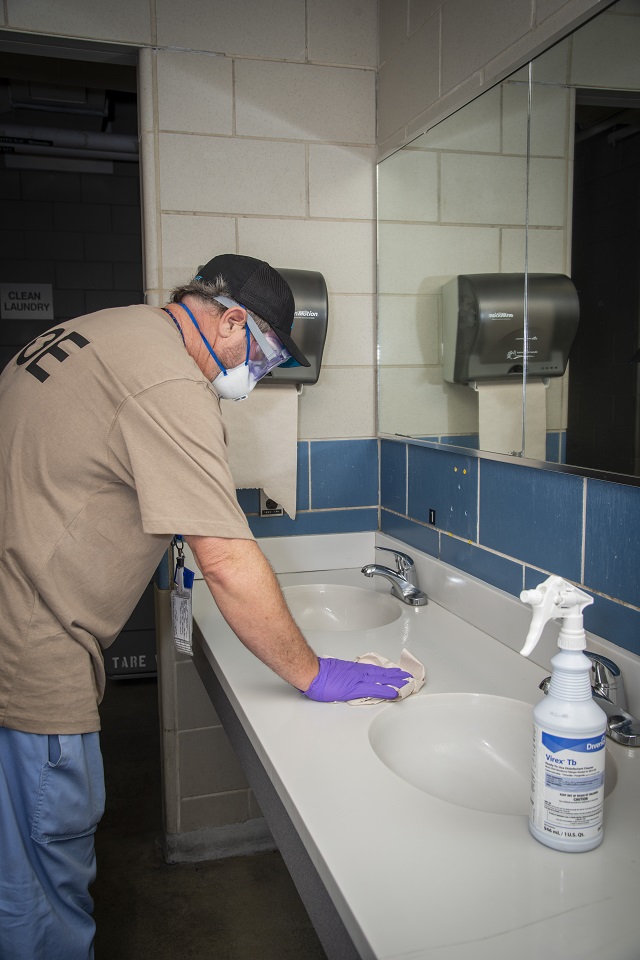

Y-12 Building Services and Lawler-Wood Maintenance and Facilities Technicians continue to disinfect commonly used areas and ensure their safety using face masks and gloves. |

When the presence of COVID-19 approached our corner of the world, causing many to brace for impact, Pantex Utilities and Maintenance, Y-12 Building Services, and Lawler Wood Maintenance and Facilities technicians at both sites were called to action. As the first line of defense against germs on site, these professionals are responsible for contributing to the overall health of employees especially during viral seasons. Only this time, they were courageously working against a different and unknown pathogen.

Armed with a dedicated task force, N95 respirators, gloves, goggles, and other necessary personal protective equipment, teams have worked quickly and diligently over the course of the outbreak to sanitize surfaces and spaces throughout Pantex and Y-12 facilities.

“We have a very professional team of building services employees who take safety very seriously,” said Y-12 Building Services Supervisor Nate Criswell. “In addition to our routine best practices, we discussed the virus more in depth and shared as much information as we could get our hands on in regards to emerging best practices as it relates to cleaning, PPE, and hygiene.”

Increased cleaning duties to twice a shift, along with the everyday janitorial duties, made for long days and even some extra hours on the weekends to maintain 24/7 operations.

“Our team performed at a high level,” Johnny Heredia, Pantex Infrastructure specialist, said. “The whole department was focused on the same goal: not getting anyone sick. We sometimes changed what we were doing in order to achieve the goals in an even more effective and efficient manner. Our team adapted and has stepped up our activities to maintain productivity.”

Already ahead of the curve in terms of safety processes and equipment, there weren’t many standard precautions for the building services team to take that weren’t already in place. Through team briefings, crews were refreshed on the differences and processes for cleaning, sanitizing, disinfecting, choosing the right chemicals for the job, and using correct PPE at all times. With plans drawn and scheduled, personnel were ready to eliminate the wake of the virus.

“Early on, our team was asked to respond to situations where employees were being sent home with symptoms or had been confirmed to have the virus,” Criswell said. “Through preparation, knowledge, and having the proper PPE, our teams deployed out to these responses more confident in the fact that they were protected and they knew the best ways to treat these areas to prevent further spread.”

As attention was directed to slowing the spread, crews began expanding to common zones, offices, breakrooms, waiting areas, etc. At the John C. Drummond Center, Lawler Wood Pantex also took advantage of reduced personnel onsite to deep clean areas such as air filters, windowsills, elevator shafts, and floors.

Throughout Jack Case Center and New Hope Center, Lawler Wood Y-12’s first, second, and third shift crews performed efforts beyond routine deep cleaning.

“Lawler Wood Y-12 employees have worked tirelessly 24/7, often overtime, to respond to requests for additional deep cleaning and disinfecting areas,” said Lawler Wood Y-12 Facility Manager Vicky Bowling. “We greatly appreciate these efforts.”

For Y-12 Building Services, members were divided into teams of two using Clorox 360 equipment. One person to help set up the area and direct the disinfectant cord, and one person to spray. This resulted in an efficient process to cover more ground. Successful disinfection sweeps were completed when all requested areas were sprayed, labeled, dated, and closed.

“I have continuously reminded my folks that what they do day in and day out matters more than they know,” Criswell said. “We are working tirelessly to keep our work family and our nation’s valuable nuclear workers safe and healthy.”

Fearless and focused, both teams remained dedicated to the safety of the mission by taking pride in the details of their work. All the while, knowingly protecting the site’s most precious assets — its people.

“Thank you to who are putting in long days to make sure we have access to the necessities during an immensely challenging time,” Heredia said. “We know you are doing crucial work, and we appreciate you. We couldn’t get through this without you.”

Mandy Miller of Lawler Wood Pantex cleans and disinfects the breakrooms in the JCDC.

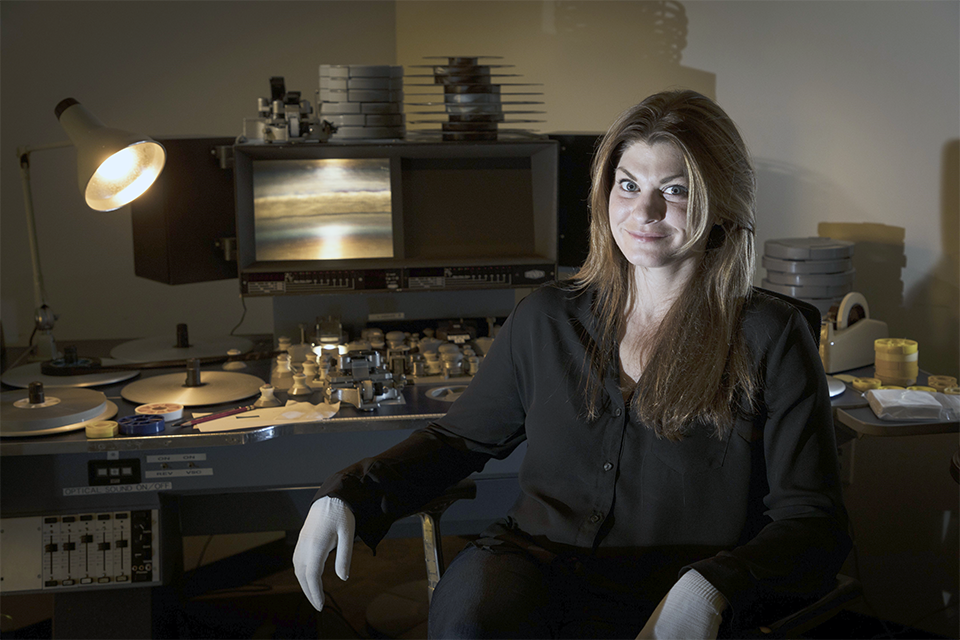

Y‑12 archivist Natalie Hansen recently obtained her digital archivist certification. She is already a certified archivist, but this newest certificate covers digital archiving in a more focused and specialized manner.

“I technically earned a ‘Digital Archives Specialist Certificate’ through the Society of American Archivists,” Hansen said. “This more specialized certificate deals with the special problems presented by digital records. I took about 40 hours of courses over the last year. I took the last course and studied for the comprehensive exam while we were teleworking. The comprehensive exam is one hundred questions and is SUPER HARD because it covers all kinds of digital archiving.”

Now Hansen is prepped on archiving web pages, creating trusted digital repositories, best practices for safeguarding personally identifiable information and sensitive information in a variety of documents, and creating detailed preservation metadata.

“With us being a DOE site, as archivist, I have to follow curation and preservation best practices to ensure our records meet DOE requirements and National Archives and Records standards. We are obligated to offer our permanent records to NARA for them to keep indefinitely, so we take our role in preserving them seriously,” she said.

“The knowledge I gained will help ensure our media records are authentic and reliable sources of information about operations. If our records are preserved well and we know they are credible, we can rely on the information in them and use them in the present to make good decisions about our current practice, and in the future they will be able to look back and understand exactly what went on at Y‑12.”

Y-12 certified digital archivist Natalie Hansen.

In late winter, Roane State Community College partnered with Y-12 to develop a new Cybersecurity Summer Camp for middle and high school students. What started as an in person camp to be held Roane State’s Oak Ridge Branch Campus will now be a virtual camp due to the COVID 19 pandemic.

“Y-12 is pleased to be able to sponsor two technology camps and provide students a high quality remote instruction experience with a professor from Roane State Community College,” Waldschlager said. “This virtual Cybersecurity Camp is the perfect way to sharpen STEM skills and bond with new friends in the comfort of their home.”

The high school camp session planned for June filled up quickly when registration opened in March, but a few spots remain for the middle school session to be held in early July.

"Technology camps expose students to skills beyond academics, allowing them to apply what they learn at school in a different context or environment, and developing them as well rounded adults. While we wanted to have an in person camp, offering this camp virtually adds to the excitement of the topic and should be engaging to students,” Waldschlager said.

A recent Roane State news release stated, “Roane State is working with Y-12 to inspire students — our next generation workforce — to develop their cyber skills and talents.”

Topics of the camp include digital forensics, IP scanning, data reconnaissance, and more. While the sessions have switched from in person to virtual, campers will still be expected to honor the time commitment as planned. Roane State professor George Meghabgha is teaching the class. He and Waldschlager were featured on a WATE news segment in March.

In March, Roane State professor George Meghabgha (center) and Y-12’s Kristin Waldschlager visited the set of WATE and talk to anchor Bo Williams about the Cybersecurity Summer Camp.

In response to the COVID-19 pandemic, many employees from both Y-12 and Pantex have become “mask makers” using their skills and talents behind a sewing machine to make masks for their friends,

neighbors and coworkers.

Pantexan Charlotte Thomas and her husband Brian Thomas |

Pantexan Charlotte Thomas has made more than 250 masks, along with the help of her husband Brian Thomas, Potter County Sheriff. He wanted to make sure his people working in the fields and those working in the jail had masks, but like everyone else they couldn’t order any. So Charlotte reached out to a friend from Sunday school who sews and asked for help. The friend directed Charlotte to a YouTube site with a 15-minute mask. On that first day they didn’t even complete one mask, but before the weekend was over they had finished 5 and by the next weekend they’d completed 25. Masks were distributed to their daughter who is an RN working in home health, River Road ISD, and others along with the Potter County Sheriff’s Office.

Charlotte said “Once the picture got out of Brian learning to sew – he had several people call and offer to make masks for him so he very graciously said thank you. And now it is not such a frantic chore to hurry up and finish them. But when you have a family that is comprised of a first responder, a nurse, and a teacher – you learn from the start to give back to the community – they work in those professions because they love serving and that is why we love them. So you help them in any way you can.”

Fellow Pantexan Lauri Minton has also been busy making masks for friends, family, and people in the medical field to wear over their N-95 masks. After her teleworking day ends and on weekends she has made more than 115 masks and a few surgical style hats for a neighbor who is a nurse practitioner in a local pediatric clinic.

Lauri said “I made some for the IS&S folks at Pantex who were issuing laptops and tokens so that many of us could telework; I think having the masks available helped ease their anxieties about exposure risks.”

Y-12er Jennifer Lawson has lost count of how many masks she and her sister have made, but estimate they’re up to around 100.

Jennifer said making masks is a way she can feel like she’s helping people during this scary time. “They at least have the protection of a mask, and in a fabric they chose,” she said. “I view it as a service project and a way to pay forward all the blessings I have. I still have my job, and am able to work from the safety of my home. Also, lots of people don’t know how to sew, and sewing machines are scarce, along with elastic, fabric, and thread.”

Jennifer and her sister don’t accept payment for the masks they make, because she says the joy come from the giving.

“If people insisted, we asked them to find some way to help someone else or make a donation,” she said. “That way, we keep it going. Plus, people have been sending photos wearing the masks they picked out and seeing those just makes my week.”

Another Pantexan Terri Woodruff has also made masks for friends and coworkers. To date she has made between 150-175 masks and continues to make more as people request them.

Lauri also said “most of us are not doing this for the attention or for recognition – I am personally doing it because I feel called to do it (as a Christian). I have been blessed with MUCH, and ‘to whom much is given, much is expected.’”

We salute these and ALL of the “mask makers” of CNS for their contributions to their family, friends, coworkers, and our communities at large.

Former Y-12 employee Sheila Gideon and her family wear masks made by Jennifer Lawson and her sister.

Pantexans and Y 12ers are making masks for coworkers, family members, and friends.