Y-12 Blog

Employees drove United Way toward a better future with donations raised from a car show and “Flock Your Friends”

Employees drove United Way toward a better future with donations raised from a car show and “Flock Your Friends”

Y-12ers again showed their giving spirit during the 2019 United Way campaign. Donations determined the winner in the car show. Scott and Mary Lou Underwood’s 1972 Corvette Stingray and Mike Antonas’ 1975 AMC Pacer won first and second place, respectively.

New this year was the opportunity to “Flock your Friends.” In exchange for a donation to United Way, bright, pink flamingoes of all sizes flocked to your coworkers’ offices. Employees could pay to flock an office yourself, or for a healthy donation, they could anonymously flock a friend with “certified flamingo technicians” delivering the birds. The more than $2,000 in donations was added to employees’ contributions through payroll deduction.

“I have seen the heart of our employees consistently in the nearly 20 years I’ve been at Y-12, and it still fills me with pride every time I see it,” said Amy Wilson, the 2019 Y-12 United Way campaign chair. “I had the opportunity at the kickoff to see a lot of laughter and a lot of giving. I love that even our awesome volunteers were having a good time while serving the community.”

Members of the Atomic Trades and Labor Council and the Knoxville Building and Construction Trades Council share insight with students about career opportunities in the crafts/trades fields within the Nuclear Security Enterprise.

During the school year, CNS employees have opportunities to volunteer with students and share their knowledge. This year, Y-12 has added several educational outreach events that focused on the various trade careers available within the enterprise.

Students from Meigs County visited Y-12 this fall and explored tools of the trade and asked questions. Y-12 employees and members of the Atomic Trades and Labor Council and the Knoxville Building and Construction Trades Council staffed the booths allowing students to interact with electricians, carpenters, insulators, painters, and machinists.

“With today’s need for skilled labor, it’s good to have kids see their options aside from college,” Jared Kesterson, a carpenter and volunteer, said.

Monica Lewis, a carpenter at Y-12 for 29 years, said, “By working and volunteering these events, I hope to inspire and encourage young women to enter this primarily male dominant field.”

Scott Underwood, Senior Director of Y-12 Infrastructure, addresses volunteers at the most recent Help the Smokies Day.

Y-12 employees, retirees, and family members joined Oak Ridge National Laboratory and National Park Service employees for a work day at the Great Smoky Mountains Nation Park’s Chimneys picnic area. The crew completed work on the lower end of the area by refreshing the rock base, filling in fall hazards and drop-offs that could affect driving and repairing damaged hand rails. The team also removed leaves and repaired or replaced timbers that provide the base for the tables and grills across the area. As part of effort to reduce damage to tabletops from hot cooking utensils, the team also installed new hot plates across picnic area.

These efforts were the latest in the Help the Smokies project that has been ongoing since 1996.

The construction team has completed the first level walls of the Uranium Processing Facility Main Process Building.

The construction team has completed the first level walls of the Uranium Processing Facility Main Process Building.

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months. First level walls are complete, structural steel is going up in the east and west halves, and preparation is underway for second level concrete placements.

“There’s been a lot of progress at the Main Process Building recently,” said MPB Area Manager Matt Nuckols. “We have great construction crews out there, and they’re working hard to keep pace with our schedule. We’re going to continue this momentum through the end of this calendar year and push hard to get the building ready for equipment installation next year.”

UPF carpenters from local union 50 in Oak Ridge, Tennessee, celebrated completion of the first level walls in October. The detail work required for the 28 wall sections was a challenge, and the team will use those lessons learned in planning for placement of the 28- to 54-feet walls for the next level of the building.

Pace is picking up with installation of structural steel in the east and west halves of the building. Keeping materials close and ensuring crane availability has helped drive momentum. Skilled craft employees are placing steel columns that weigh 20 tons each. Work on the east side started first, so ironworkers there are busy installing rebar, embeds, and penetrations to prepare for concrete placements.

“Structural steel is the gateway to upper decking concrete,” Nuckols said. “The crew is really getting after it, knowing our objective is to place the east side second level floor this year.”

The first upper decking concrete placement is scheduled for early November, starting on the far east side. A total of five placements, all with bottom and top rebar layers, are required for each side of the MPB.

Moving beyond construction, the MPB team will start receiving and installing upper commodities, like fire protection headers and cable tray, in the next few months. Equipment deliveries, like process skids and gloveboxes, will start arriving in the spring.

Rebar, embeds, and penetrations are installed on the second level of the Uranium Processing Facility Main Process Building to prepare for upper deck concrete placements.

Rebar, embeds, and penetrations are installed on the second level of the Uranium Processing Facility Main Process Building to prepare for upper deck concrete placements.

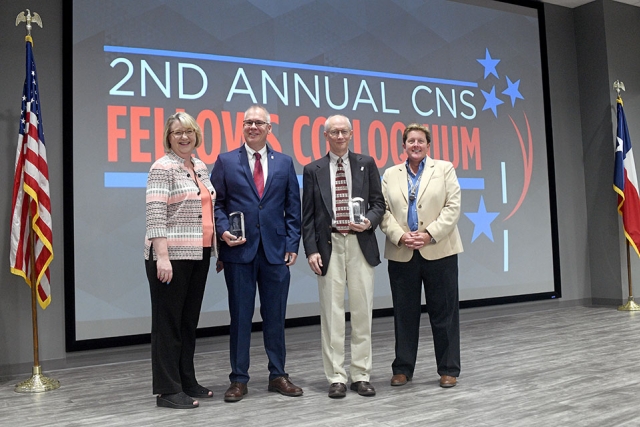

Chief Operating Officer Michelle Reichert (left) and CNS Vice President Linda Bauer (right) congratulate the latest CNS Fellows: Neil Koone (left) and John Prazniak.

Chief Operating Officer Michelle Reichert (left) and CNS Vice President Linda Bauer (right) congratulate the latest CNS Fellows: Neil Koone (left) and John Prazniak.

Some of CNS’s most talented scientists and engineers presented at the 2nd Annual CNS Fellows Colloquium, August 20 at Pantex. The all-day event celebrated the addition of two new Fellows and participants heard from the Fellows about the incredible work being done in the fields of uranium, metallurgy, electromagnetics, surveillance, component analysis, and others related to the important and unique work Pantex and Y-12 do for the Nuclear Security Enterprise.

Michelle Reichert, CNS chief operating officer, gave the opening remarks on how the Fellows program encourages innovation in our prime centers of excellence such as high explosives and uranium processing, but also in other designations that help us strive for advancements in these fields.

“We cannot rest on our laurels. We will continue to lead in these fields and advance these vital capabilities for our nation,” she said. “To accomplish these goals, we must engage the best and brightest individuals in the NSE — our CNS Fellows.”

The newest Fellows, one Pantexan and one Y-12er, Neil Koone and John Prazniak, took on the roles of Electromagnetics Fellow and Uranium Fellow, respectively, and were pinned an official member of the fellowship to join Alan Moore (Metallurgy), Lorelei Woods (Pantex Surveillance/Component Analysis), and Vincent Lamberti (Y-12 Surveillance/Component Analysis). Reichert further described what makes the Fellow a valuable asset.

“Working in our most critical capability areas, our Fellows bridge the gap between a shiny new idea and production-scale technology, between our past and the future of our operations,” Reichert said. “Because we are production sites, our Fellows have the unique opportunity to apply new technologies directly to production use.”

All five CNS Fellows gave a keynote offering background, current trends, and future projects in their respective fields. Those in attendance learned about gas sampling operations, electrorefining in uranium processing, Y-12 history and metallurgy, lightning detection and electrostatic discharge, and the future of surveillance. The Fellows’ keynote addresses will be posted online. You can earn professional development hours for Professional Engineer and Project Management Professional credits for each keynote watched. Get supervisor permission before watching videos during work hours. To receive PDH credit, email Ashley Stowe.

The colloquium included a poster session where 20 Pantex and Y-12 presenters highlighted innovative projects taking place at both sites — from 3D printed parts to newly designed buildings.

Next year’s colloquium will take place at Y-12, and other Fellows will be announced to join the ranks in other fields such as lithium/special nuclear material, high explosives, nonproliferation, and advanced manufacturing.

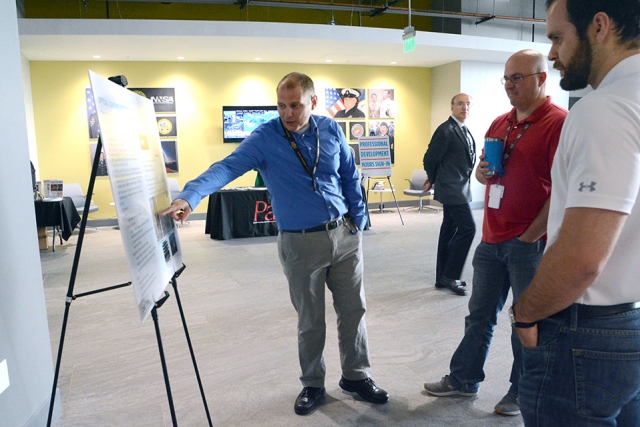

Fellow Alan Moore talks to attendees at the 2nd Annual CNS Fellows Colloquium.

Fellow Alan Moore talks to attendees at the 2nd Annual CNS Fellows Colloquium.

From left: Lorelei Woods, Vincent Lamberti, Alan Moore, Ashley Stowe, Michelle Reichert, and Linda Bauer at the 2nd Annual CNS Fellows Colloquium.

From left: Lorelei Woods, Vincent Lamberti, Alan Moore, Ashley Stowe, Michelle Reichert, and Linda Bauer at the 2nd Annual CNS Fellows Colloquium.

Ashley Stowe (left) talks to an attendee at the 2nd Annual CNS Fellows Colloquium.

Ashley Stowe (left) talks to an attendee at the 2nd Annual CNS Fellows Colloquium.

The 2nd Annual CNS Fellows Colloquium poster session

The 2nd Annual CNS Fellows Colloquium poster session

From left: Neil Koone, Alan Moore, Lorelei Woods, Vincent Lamberti, and John Prazniak, the CNS Fellows

From left: Neil Koone, Alan Moore, Lorelei Woods, Vincent Lamberti, and John Prazniak, the CNS Fellows