Y-12 Blog

For more than 10 years, the Y-12 Apprenticeship Program has been in business, training employees for professions in trades like pipefitters, electricians, machinists, and ironworkers. The program, restarted in 2008 as a cost savings proposal, allows hands-on training for key positions within the site.

Will Farmer of Y-12 Infrastructure said, “We’re at a junction where a significant percentage of the skilled craft personnel supporting vital activities are retirement-eligible or will be retirement-eligible within the next five years. The Apprenticeship Program allows us to address this issue by developing a strategic staffing approach that focuses on attrition projections.”

Apprentice graduate and now apprentice supervisor Zach Yost said, “The program is important to CNS and Y-12 because there is a need for skilled craft workers in our current and future mission scope. The apprentices won’t just learn the skills to become a Department of Labor–recognized journey worker; they will also be uniquely qualified to perform their skilled trade within the compliance-driven environment of Y-12.”

Infrastructure works with the Atomic Trades and Labor Council, Production, and Human Resources to develop a five-year look-ahead staffing plan to meet the resource demand in critical-skill craft positions.

“Currently, we have 21 apprentices in three types of apprenticeships that range from three years to five years,” Farmer said. “Our partnership with the ATLC provides selected candidates the opportunity to learn a skill trade through classroom learning and hands-on experience with Y-12–specific equipment, systems, and processes that support our country’s national security initiatives. Through the program, we’re enabling personal growth for the candidates while ensuring continued Y-12 mission success now and for the future.”

Chris Drinnon, a fifth-year pipefitter apprentice who will finish in September, recommends the program. “With the rising cost of college tuition, apprenticeship programs are a great alternative. Plus, America is experiencing a major shortage of qualified trade workers, and apprenticeship programs are a solution to this ongoing problem.”

During 2019, Y-12 began educating tomorrow’s workforce about the opportunities available in trades by holding educational outreach events that focus on the various trades careers available. At the events, students interact with electricians, carpenters, insulators, painters, and machinists. ATLC members share career plans and the advantages of being an apprentice and “earning while they learn.”

Katie Mead is a first-year apprentice as an outside machinist and agrees with Drinnon. “It is a great opportunity to further your education, learn a new skill or trade, and avoid having the large amount of student loans that come with traditional schooling.”

Drinnon said, “Aside from apprenticeship classwork, gaining knowledge out in the field of building processes and systems has been vital. Currently, apprentices work three-month rotations in different workshops throughout Y-12. By doing this, it allows each apprentice to gain valuable knowledge in multiple areas.”

“Hands-on training, company training programs, Red Vector training modules, and school offer a wide range of educational tools and information,” Mead said. “By combining all of the knowledge obtained in these programs, I feel like that is what is helping to mold me into being the best outside machinist I can be.”

As most of us know, reaching a goal often takes a little stretching to accomplish it, and being an apprentice is no different.

“The hardest part for me has been the late nights getting home from class. For nine months a year and two times a week, 18-hour days are tough, especially as a 48-year-old with a family,” Drinnon said.

Mead expects the toughest part to be the group rotations. “You only have a short amount of time with each group, so it can be tough having to adjust each time.”

Drinnon offered advice to Mead and other new apprentices: “There will be tons of information thrown your way throughout this process. It can be overwhelming. Be patient.”

The apprentices’ dedication and experience can also help them become tomorrow’s leaders. Yost said, “Based on recent history, the individuals going through the apprenticeship are also the future leaders within Maintenance Execution and other organizations.”

Monte Branstetter, left, a pipefitter apprentice, and Chris Drinnon, a fifth-year pipefitter apprentice

Monte Branstetter, left, a pipefitter apprentice, and Chris Drinnon, a fifth-year pipefitter apprentice  Alexandra Phillips, an ironworker/rigger apprentice

Alexandra Phillips, an ironworker/rigger apprentice Katie Mead, a first-year apprentice as an outside machinist

Katie Mead, a first-year apprentice as an outside machinist Scott McAlister, an apprentice electrician

Scott McAlister, an apprentice electrician Matthew Hutzler, an electrician apprentice who works on cranes/elevators at the site

Matthew Hutzler, an electrician apprentice who works on cranes/elevators at the site Chelsea Adkisson, an electrician apprentice

Chelsea Adkisson, an electrician apprentice

Y-12ers have stepped up to support one of our own, Y-12 Engineering’s Tony Grappin, whose son was diagnosed with leukemia. |

In 2018, Tony Grappin of Y-12 Engineering shared that his son Alex was diagnosed with leukemia. In October 2018, Y-12ers stepped up to have the best turnout for a MEDIC blood drive, all in honor of Alex.

Tony shared the following:

In April 2019, Alex entered maintenance, which is when we were supposed to be able to breathe easier. Life would be returning to normal. Two days after the maintenance milestone, though, he suffered a reaction from his chemo that caused inflammation in his white matter. He’s still recovering from this 10 months later, and he still has a good way to go.

Every year, the Knoxville chapter of the Leukemia and Lymphoma Society chooses two children to spotlight. Alex was chosen as Boy of the Year for 2020! I would be extremely grateful if you would like to help us meet our fundraising goal of $25,000. So far, we’re over $5,000. If you would like to donate, please visit Alex’s page at https://pages.lls.org/mwoy/tn/knox20/agrappin.

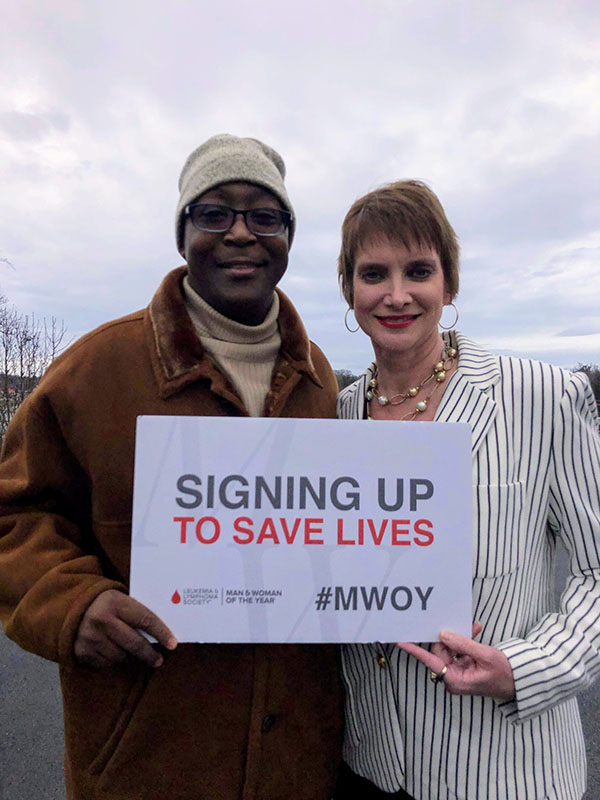

For more than 15 years, Y-12 has supported the LLS Light the Night walk held in October each year. For 2020, Y-12 has two ties to the LLS person/child of the year with Alex Grappin as the 2020 Boy of the Year, and Y-12er Tony White is in the running for the Man of the Year.

He’s a beloved member of the Y-12 family who bleeds orange and is a University of Tennessee Vol for Life. Now, Tony White, Protective Force Operations, is up for the Leukemia and Lymphoma Society’s Man of the Year and shared the following.

Nobody is ready for cancer — believe me I know. When I was diagnosed with Acute Myeloid Leukemia, I knew I was not going down without a fight, but cancer is not the kind of thing that you fight on your own. Thanks to God, my family, my friends, the VFL community, and the Leukemia and Lymphoma Society, I am in remission.

Less than a year ago, I was receiving a bone marrow transplant. Now, I am asking for your help to help me help others stricken with blood cancers.

Each year the LLS launches its Man and Woman of the Year fundraising campaign. I am honored to be named as one of the five men nominated this year. From February 20, 2020, through May 1, 2020, my team and I have committed to raise as much money as we can. Every dollar we raise counts as one vote, and the candidate whose team tallies the most votes will win the prestigious title of ‘Man or Woman of the Year.’

White played for the University of Tennessee from 1983 through 1987. He was first in the Southeastern Conference for points per game (22.2 in 85-86, and 24.5 in 86-87) and free throws (165 in 86-87). He was the SEC player of the year in his final season (86-87).

Barbie White of Safety & Industrial Hygiene and Tony’s wife said Tony is doing well and remains in great spirits. “He’s fundraising for LLS and wants to help others who are fighting blood cancers. We have several events planned, and I encourage anyone interested in donating or seeing how Tony is doing to visit his LLS page (link: https://pages.lls.org/mwoy/tn/knox20/twhite).”

For more than 15 years, Y-12 has supported the LLS Light the Night walk held in October each year. The Whites were part of the 2019 Y-12 team and plan to participate in 2020.

For 2020, Y-12 has two ties to the LLS person/child of the year as Alex Grappin, son of Tony Grappin of Y-12 Engineering, is the 2020 Boy of the Year, and White is in the running for the Man of the Year.

Through a contribution from the Y-12 Community Investment Fund, Shangri-La Therapeutic Academy of Riding’s (STAR) Heroes & Horses program provided 375 hours of programming and rehabilitation for veterans in 2019.

With every stall door opened, the veterans at Shangri-La Therapeutic Academy of Riding’s (STAR) Heroes & Horses program, begin a life-altering journey to a human-to-horse connection.

Based on the Y-12 Community Investment Fund’s contribution of $5,000, the entire program is provided at no cost to every participating veteran. In 2019, STAR provided 375 hours of programming and rehabilitation for the veterans.

“It’s truly a hidden gem in Knoxville,” said Cathy Dolson, STAR Heroes & Horses instructor. “The veterans and their families have told us that they are different people when they come home from a lesson.”

More than a riding lesson

Heroes & Horses operates in semesters and offers one-hour lessons each week to veterans with disabilities or other special challenges, including traumatic brain injury, amputation, sensory loss, and post-traumatic stress disorder. Each lesson includes tasks and objectives that focus on improving coordination, developing core strength, increasing self-esteem, and providing stress relief on and off the horse. Volunteers in this program are fellow service members who participate in an extensive therapeutic riding and equine assisted training to accommodate the riders.

“Our veterans say that coming here is the best part of their week,” said Melissa Abbey, STAR director of services.

For 10 years, the program has provided vital skills and rehabilitation to veterans in East Tennessee. As members of the Professional Association of Therapeutic Horsemanship International (PATH), “STAR is considered the gold standard in our area,” Dolson said. As a PATH member, STAR follows therapy safety program initiatives and training guidelines for instructors, ensuring safe and optimal outcomes for its veterans and horses.

Changing lives with each stride

Winston Churchill once said, "There is something about the outside of a horse that is good for the inside of a man.” STAR embodies this adage by focusing on the therapeutic impact horses have on the veterans. Whether they are learning how to properly groom a horse or dismount after a lesson, every action is one step closer to restoring their trust, confidence, and purpose.

During a lesson on riding bareback, veterans learn how physical and mental stress can affect the outcome of their ride and the horse. The bonds the veterans share with their four-legged counterparts and the support of staff and volunteers have saved and enriched lives by actively replacing tension with tenderness.

An atmosphere for healing

While the sound of whinnies echo in the barn, the smell and feeling of the fresh mountain air from the East Tennessee foothills creates a peaceful atmosphere at STAR. “No matter what life has thrown at them,” Dolson said, “the veterans are going back to an activity and time in their life here when everything was fantastic, while learning how to redevelop relationships and camaraderie.”

For the veterans from Vietnam through Desert Storm, STAR is not only a center for hands-on experiences with horses. The academy is a place of relaxation and sanctuary that helps them cope with their post-service lives. “Several of our veterans have admitted that this is a place where they finally don’t have to look over their shoulders,” Abbey said.

By working with the East Tennessee Foundation, the Y-12 Community Investment Fund has provided opportunities for employees to award grants benefiting nonprofit organizations like STAR in its 20-county service area.

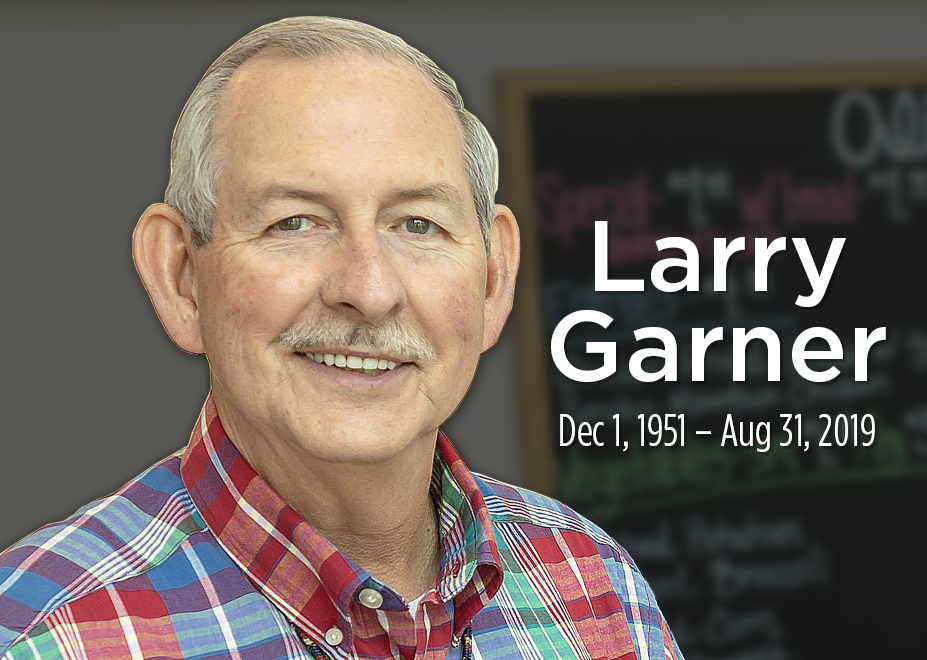

His smile is one you miss when you visit the sandwich area at what is now known as the Larry Garner Cafeteria. Garner, owner of Oliver’s, the food vendor that manages the Y-12 cafeteria and canteen, passed away last August. Bobby “Homey” Mullins, facility manager for the Y-12 Jack Case and New Hope centers, suggested naming the cafeteria after Garner. In Mullins’ own words, here is why.

“Larry was a team player when it came to Y-12. Whenever called upon to provide food service for employees or the CEO, whatever he was asked to do, he delivered. From Christmas parties for kids to short-notice events for VIPs, whether it was a guest box lunch or fine dining on china, Larry and his crew would have food ready for Y-12 employees and guests.

“Larry fed all the Y-12 veterans every Veterans Day at no cost to them. All of it came out of his pocket. If a U.S. service member in uniform was visiting Y-12, Larry fed them for free. At Thanksgiving, he would provide a good meal for about the cost of the food.

“He was always looking for better, faster ways to get employees through the cafeteria line and checked out because he knew that the employees only had so much time for lunch. He wanted them to be able to sit, eat, and enjoy their food. If something wasn’t right or wasn’t what was asked for, he would make it right.

“Larry was a leader who led from the front. He would run the grill, make sandwiches, run the deep fryer, whatever it took to make things run smoothly. He would jump in and make it happen. He always considered himself and his company part of the Y-12 team. He was a professional with a smile on his face and a can do attitude who loved what he did. He had a way of making people smile. He was our friend, and we will miss him.”