Y-12 Blog

Y-12ers tour the Amazon Fulfillment Center in Chattanooga, which generated ideas such as increasing awareness of customer requirements and improving visual management and inventory systems.

Y-12ers tour the Amazon Fulfillment Center in Chattanooga, which generated ideas such as increasing awareness of customer requirements and improving visual management and inventory systems.

Product delivery is dominated by Amazon, which ships an average of 608 million packages each year. So if you want to improving delivery and inventory control, watching operations at an Amazon Fulfillment Center is a good place to start.

Recently, a Y-12 cross-functional team visited the Chattanooga fulfillment center to benchmark best practices and to learn about innovations in warehousing and transportation.

“Amazon has some sophisticated algorithms, but the predominant tool was barcodes and barcode readers. We use barcodes and barcode readers at our sites, so this showed me that there is still a lot we can do with the tools we have,” said Reed Mullins, Production Operations director.

The team was able to follow the path from when products enter the center until they ship. While Amazon uses advanced automation in its fulfillment centers, tour participants observed that they also employ surprising storage practices for quick and efficient supply chain management. They rely on sophisticated computer systems to manage their inventory, but smaller, unrelated items are stored randomly for more efficient “picking” by employees.

Amazon fosters a mindset of “start with the customer and work backwards.” They ask the questions: What do they want? What do they need? What can I do to make the next operation better?

“It’s these simple questions that we can ask ourselves each day that invokes change and best practices. The team plans to use these observations to challenge the way we think about delivery and inventory control of items here at Y‑12,” said Paula Goins, program manager for Materials Stewardship. “For example, I was not expecting to see small items stored in random places, but, after it was explained, it makes perfect sense for their operations,” Goins said.

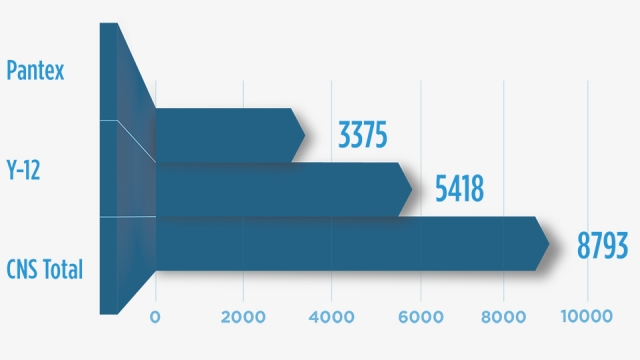

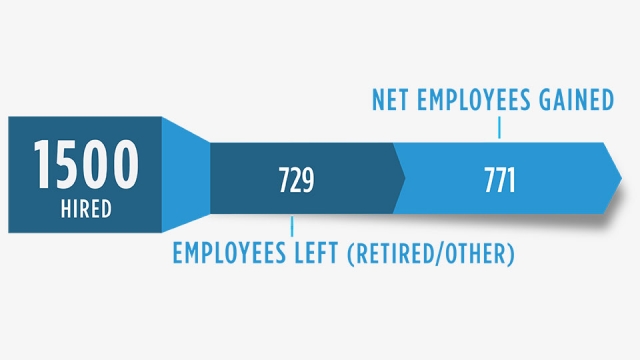

There are 1,500 new faces at CNS, and they all arrived in 2018.

Last year CNS was busy building the workforce for the future at Pantex and Y-12. Recruiting the next generation of professionals to support national security is one of the top priorities for the Nuclear Security Enterprise.

In total between Pantex and Y‑12, 1,500 employees were hired in calendar year 2018. This influx of personnel adds to our talented and diverse workforce and ensures critical skills and knowledge are maintained and transferred to continually support our important mission.

Who are all the new hires?

Mission Engineering, Operations Support, and the Uranium Processing Facility project saw the biggest personnel increases across both sites to account for attrition and work demand. Employees spanned experience levels from new graduates, to experienced senior individuals, to construction hires.

“The influx of new talent bolstered our ability to support increased project execution, implement new or restarted mission capabilities, and begin to dent long‑standing backlog activities,” explained Ken Keith, Mission Engineering senior director.

More than 400 skilled craftspersons and professionals joined the UPF project in 2018 as the first wave of construction hiring. The project will continue to hire throughout fiscal year 2019, peaking at about 2,200 craftspersons and professionals in 2020.

Come work for us

If you’re interested in working for CNS, you’ll find us at job fairs and hiring conferences. In 2018, CNS representatives attended 35 job fairs or hiring conferences across the country. We also hosted 47 summer interns, bringing 20 on as full-time employees. Watch our social media accounts to see when we’ll be in your area.

From left to right: CNS Construction Superintendent Paul Champ; SIS Federal Project Director Don Peters; DOE Under Secretary for Nuclear Security and NNSA Administrator Lisa Gordon-Hagerty; UPF Federal Project Director Dale Christenson; UPF Contracting Officer Michael Bocskovits; and USACE Project Manager Joe Duncan.

From left to right: CNS Construction Superintendent Paul Champ; SIS Federal Project Director Don Peters; DOE Under Secretary for Nuclear Security and NNSA Administrator Lisa Gordon-Hagerty; UPF Federal Project Director Dale Christenson; UPF Contracting Officer Michael Bocskovits; and USACE Project Manager Joe Duncan.

The Uranium Processing Facility Project Site Infrastructure and Services Subproject team was recently honored with the 2018 Department of Energy Project Management Achievement Award.

SIS, UPF’s second of seven subprojects, was completed two months ahead of schedule and $18M under budget in February 2018.

SIS included the 65,000 square foot Construction Support Building which provides office space for more than 300 UPF Project personnel and is the Y-12 National Security Complex’s first Leadership in Energy and Environmental Design Gold building.

SIS also included the fully automated, continuous mix concrete batch plant designed to produce 300 cubic yards of concrete per hour. The batch plant and five concrete trucks are on site and dedicated solely to UPF, providing construction schedule flexibility and immediate response to quality issues.

Other SIS deliverables included building demolition, utility work, site grading and installation of new erosion protection and security features.

To execute the work, NNSA employed an integrated acquisition and project management strategy, including partnerships with U.S. Army Corps of Engineers and Consolidated Nuclear Security, LLC. These partnerships capitalized on USACE’s expertise in non-nuclear construction and fixed-price contracting and CNS’s familiarity with the existing Y-12 site infrastructure and mission. Both CNS and USACE used fixed unit rate subcontracts to execute the majority of the work.

“I am very proud of our how well USACE and CNS worked together to safely deliver SIS ahead of schedule and under budget,” said SIS Federal Project Director Don Peters. “Our unique partnership provided the best value to the government and to American taxpayers. I am honored that DOE recognized our success with this prestigious award.”

Members of the SIS team were presented the award by DOE Under Secretary for Nuclear Security and National Nuclear Security Administration Administrator Lisa Gordon-Hagerty at the DOE Project Management Conference held in Washington, DC.

The first vertical wall for the Main Process Building (MPB) has been placed. The wall is 27 feet tall and required 196 cubic yards of concrete.

The first vertical wall for the Main Process Building (MPB) has been placed. The wall is 27 feet tall and required 196 cubic yards of concrete.

The first vertical wall for the Main Process Building at the Uranium Processing Facility has been placed. Because this wall is part of a nuclear facility, the 196 cubic yards of concrete needed for this placement is high quality, the documentation is more thorough, and there are more rigorous evaluations.

“It’s great to see MPB go vertical,” said MPB Area Manager Matt Nuckols. “The team has worked tirelessly to transition from base and topping slabs to the rebar and formwork intensive walls. It’s exciting to see the building take shape.”

To build the 27-foot-tall wall, the outside rebar curtain layer was joined by an inside layer. Formwork was placed outside the curtains and then the concrete placed. The concrete was left to cure, or harden, for five days before the forms were removed.

Ironworkers, carpenters, and cement finishers will continue this process for the remaining 27 vertical wall sections for the MPB first floor, starting near the corners and building west.

Concrete crews finish the base slab for the Salvage and Accountability Building. Placement of the topping slabs is underway.

Concrete crews finish the base slab for the Salvage and Accountability Building. Placement of the topping slabs is underway.

The Uranium Processing Facility Project team achieved a key milestone by completing the base slabs for the three main buildings: the Mechanical Electrical Building, the Main Process Building, and most recently, the Salvage and Accountability Building. A total of 37,000 cubic yards of concrete was required for the structural base slabs. That’s enough concrete to cover a football field nearly 24 feet deep, or as tall as a two-story building.

“Achieving this milestone was the result of a lot of hard work from everyone on the team,” said SAB Deputy Area Lead Randy Holman. “They were focused on performing safely, doing it right the first time, and achieving the project milestones. With the completion of the base slabs, the team has positioned itself for future success.”

Work at the SAB continues with installation of the topping slabs underway and structural steel erection beginning in May.

The MPB base slab was completed in February, and work continues with placement of rebar curtains.

The MEB base slab was completed in July 2018. MEB is forecast to be “in the dry” in May.