Y-12 Blog

Michael Dunn Center was one of several East Tennessee organizations CNS and the ETF Neighbor to Neighbor fund helped during the COVID-19 pandemic.

“CNS sought to help community organizations respond to critical needs throughout the pandemic by providing contributions rapidly and responsibly. An important step was directing CNS Community Investment Fund dollars to the East Tennessee Foundation’s Neighbor to Neighbor Fund. Together, CNS and the Foundation were able to quickly get much-needed resources to several nonprofit organizations in East Tennessee.

Food for residential homes

The need for groceries grew exponentially for Michael Dunn Center’s residents because of the COVID-19 pandemic. The pandemic forced residents to shelter in their homes and that increased the number of meals needed each day. The cost for groceries increased roughly $70 per month for each home or more than $2,000 a month overall. Adding to the increase was the need to ensure that many of their residents, who have developmental and/or intellectual disabilities, were served proper meals because of very restrictive diets.

The Michael Dunn Center turned to East Tennessee Foundation and CNS. Through ETF's Neighbor to Neighbor Fund, the Center received a grant of $2,000 to cover the funding gap for increased groceries for their residential population.

“The CNS grant helped our staff provide the necessary groceries to meet the dietary needs of everyone we serve,” said Courtney Briley, Michael Dunn Center’s community relations coordinator.

“The safety of those we support is our top priority and being able to meet the increased need for groceries has been imperative and instrumental to each resident’s well being.”

Briley thanked CNS and ETF for providing help in a very uncertain time.

“You allowed us to continue provide services which are instrumental to the health and nutrition of those we served during a global pandemic. We met their nutritional needs so that they could remain safe in their homes,” she added.

Shipping crates of the Main Casting Glovebox Line, Group 1 in MPB East

When building the Uranium Processing Facility (UPF), the option for free, two-day shipping is seldom, if ever, an option. Many items that are ordered for the project are so specialized that it takes months – or years – to see their arrival. So when the UPF Project recently received 16 truckloads of shipping crates, the team was excited and proud to receive the heart of the Main Process Building (MPB)…gloveboxes!

This shipment of gloveboxes included the Tool Preparation and Storage section, the first of five groups of the UPF Main Casting Glovebox Line. Many of the crates were so large that they had to be opened or adjusted to fit through the 20-ft.-tall doorways of the MPB. But once inside, they fit like a glove.

Currently, group one is being installed on the first floor of MPB East and is scheduled for completion by the end of August 2021. The MPB is the last of seven UPF subprojects and, once completed, will include 242,000 square feet of casting, special oxide, and some chemical recovery processes. The main processing work will take place on the first two levels with the third floor containing support utilities.

“Thank you to our Glovebox Delivery Center teammates, Engineering, Procurement, Construction, and many others who were involved in this effort,” said Dena Volovar, UPF Project Director. “The team worked together during supplier production, COVID-19 delays, and through some challenging logistics to get us to where we are today.”

UPF Electrician inspects wiring in the 13.8kV switchgear (Per work assessment and STAART card requirements gloves are not required during the activities pictured)

Transformers are humming at the Uranium Processing Facility (UPF) as the project successfully energized medium voltage power to the Mechanical Electrical Building (MEB) during the month of June. This energization was the first connection to the Pine Ridge Substation, which the project completed in December 2019, and represents permanent power to the site.

The MEB plays the vital role of distributing power to the UPF Project. With project equipment previously running on temporary construction power, the achievement of this energization marks another step towards system operations as the MEB continues to finalize construction and progress through its testing and start-up phase.

“This energization required months of coordination between multiple entities, which included BNI Startup, BNI Engineering, CNS AHJs (authority having jurisdiction), CNS Power Operations, Subcontractors and numerous others,” said Jeremy Wilkins, UPF Start-Up Manager. “The UPF project team put in countless hours demonstrating the dedication and quality of work needed to successfully achieve this significant project milestone. It was a job well done and most importantly, it was a job done safely,”

The UPF Project successfully energized Medium Voltage Power in the Mechanical Electrical Building

“Thank you to all of our team members who made this happen. We have come a long way from what once started as a parking lot and that is solely because of every individual’s efforts on the UPF Project,” said Dena Volovar, UPF Project Director.

As the project progresses, the medium voltage power system will supply power to both the process and utility systems in the MEB, as well providing power to the other UPF buildings such as the Main Process Building and the Salvage and Accountability Building.

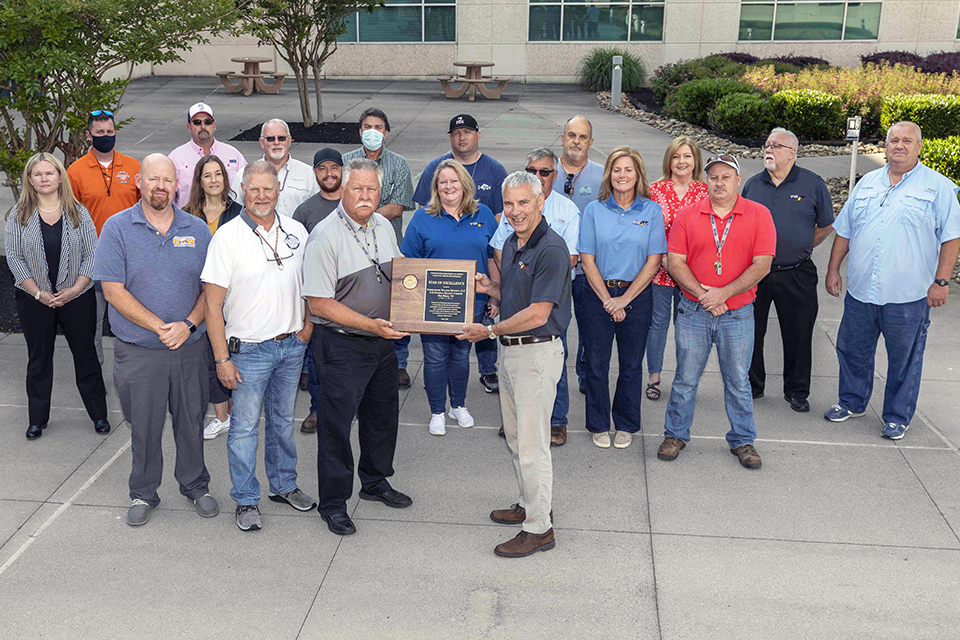

Accepting the Star of Excellence award plaque from Gene Sievers, Y-12 Site Manager, is Mike Thompson (left), president of the Atomic Trades and Labor Council, with members of the safety team and their representatives in attendance.

Y-12 recently received the Voluntary Protection Program (VPP) Star of Excellence Award from the U.S. Department of Energy (DOE). VPP promotes safety and health excellence through cooperative efforts among labor, management, and government at DOE contractor sites.

The award plaque states the following:

Through their full dedication and total commitment to the principles of VPP, they have achieved an outstanding level of performance in meeting established safety and health goals, actively conducting outreach to others, and in achieving an injury and illness rate significantly below the average of similar businesses and operations.

Gene Sievers, Y-12 Site Manager, expressed his appreciation to the team for their efforts to increase employee engagement in safety awareness. He said, “With the safety stats we’re seeing, it makes you feel good. In part, that is thanks to the work of this team.”

Thanks to teamwork, a plan to restore power during a scheduled outage kept the mission on schedule.

It’s hard to get much work done without power. That’s especially true at Pantex and Y-12, where power needs drive many production processes and where any loss of power can result in missed schedules and deliverables. At Y-12, managers faced that very problem. A failed transformer was threatening to delay important mission work that could have impacted deliverables and more than 150 workers.

“Even with a spare temporary transformer on hand, we feared it might take several weeks to retrofit the spare into this installation,” said Susan Baker, Fabrication Operations director. “We needed a solution fast.”

The solution came from the Power Operations Preventive Maintenance Program and a team of more than 100 craft, staff members, supervisors, and managers. The Power Operations team quickly developed a plan to restore power during a scheduled outage. The team identified an alternate location for the temporary transformer that required minimal modifications and developed a way to complete the process that shortened the duration of the outage. In addition, Infrastructure provided temporary lighting and power to enable some operations to resume during the week of the outage.

“We were back to full operations on the following Monday,” Baker said. “With help from many organizations, we recovered our production schedule and met our monthly deliverables.”

The effort went so well that the team was recognized by the Y-12 Safety Council, which awarded the group the site manager’s monthly safety award. The Safety Council said, “This team worked together to meet the common goal with zero injuries and without incident.”

The effort also demonstrated the importance of the Power Operations Preventive Maintenance Program. It required a tremendous amount of coordination and teamwork that was on full display during the installation of the temporary transformer.

“I want to thank every person who worked diligently during the outage,” said Ellis Scruggs, Power Operations System Health manager. “This project exemplifies what can be accomplished when we all work together for mission success.”