Y-12 Blog

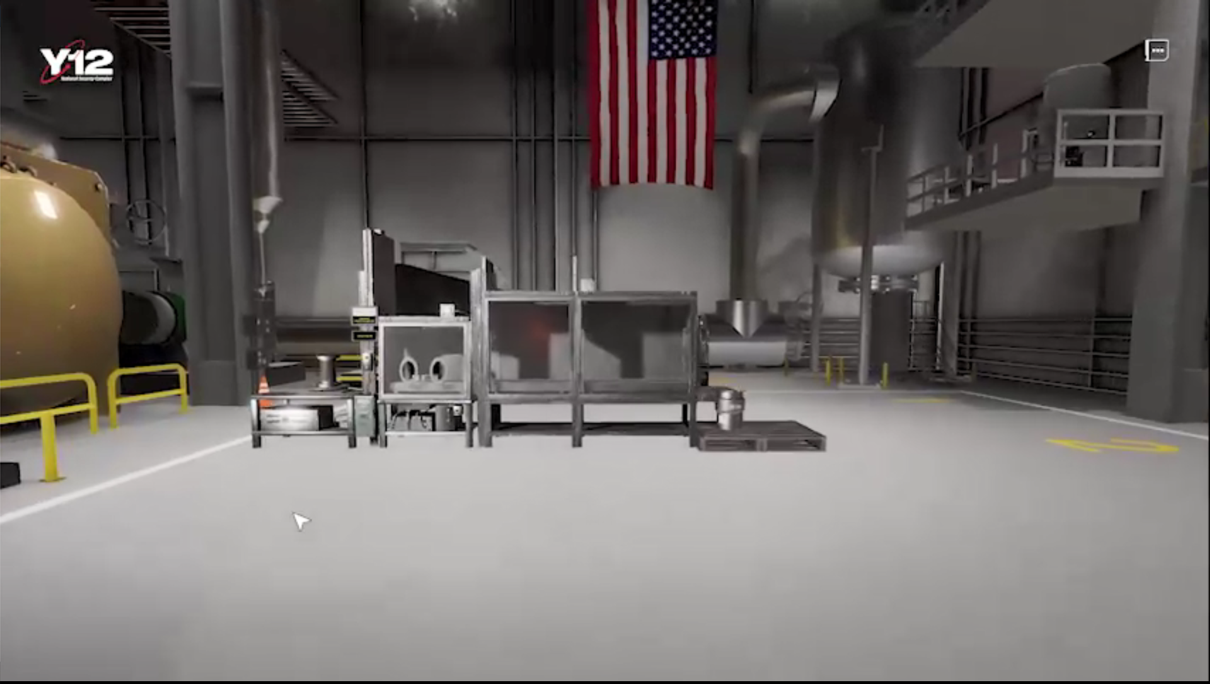

A representation of a glovebox within a digital twin allows operators to practice operations virtually before working with actual materials.

It’s no secret that Y-12 works with hazardous materials in order to deliver on the site’s missions for the nation. To protect employees, the site relies on engineered controls, such as gloveboxes, and administrative requirements, including limiting exposure to a hazard. Employees receive considerable training before they work with any materials. However, there’s really no substitute for actual experience … or is there?

The answer might lie in using digital twins to simulate real-life scenarios. A digital twin is a virtual 3D model or simulation that is a replica of a real-world product, system, or process making it a valuable training tool for high-hazard, high-consequence operations.

“You can train on scenarios that you wouldn’t want to do in the real world,” said Scott Couture, senior director of Production Research, Development and Integration. “For example, you can simulate a part breaking during microwave casting. That’s something you wouldn’t want to create in a real-world environment.”

Training first responders

At the Emergency Response Training Facility on the Oak Ridge Enhanced Technology and Training (ORETTC) campus, Director Ashley Stowe said they are now able to train first responders in a different way than before by using a virtual 3D space.

“ORETTC is using virtual reality as a more cost-effective training method for the Office of Radiological Security,” continued Stowe. “Rather than flying everyone here to train, we can now ship headsets out and bring them together in the virtual environment.”

Projecting future-state operations

Fabrication has been using a digital twin to design the Advanced Manufacturing Prototype Shop. The team had a conceptual layout in a drawing that changed many times. When they examined the space in VR, they realized the layout was not the most efficient. Now they are developing the layout in VR to give Design Engineering a place to start.

Couture said a digital twin can create an accurate and in-depth virtual representation of systems. “You can put physics behind it with process flow and capacity analysis—things that increase efficiency and reduce cost.”

The team’s experience illustrates the ease of taking a vision and making it some form of reality.

There are other advantages to using a digital twin, including demonstrating future capabilities. When new or greater work scopes are planned, a virtual tour of the future scope can be created.

Enhancing safety at UPF

Don Sproul, CNS Environment, Safety, and Health manager for the Uranium Processing Facility (UPF) Project, recognizes that while his applied-use case for a digital twin may not be as the technology was originally intended, it has been extremely effective during the construction phase of the project. The UPF leadership team has engaged with ORETTC to develop a solution to better communicate incidents and lessons learned, along with putting today’s workforce in tomorrow’s work environments.

Stowe said the technology has that “wow” factor. “When you show how it can be used, people really get excited. For UPF, they are able to walk into spaces that aren’t built yet,” he said. “The digital twin speeds up transition/commissioning time and our understanding and validation of the equipment. Employees can learn faster and test against abnormal conditions or in different configurations. These activities are mental studies now, but we can leverage the system to actually see it.”

The simulations have been well-received by the UPF Project workforce. “Many of our employees are gamers, so they are familiar with this type of presentation,” said Sproul.

Given the reception and effectiveness of these digital twins, Sproul can see the tool being used for a number of things. “I’d like to use the technology for the mobile equipment and personnel interface so employees can explore the setting and how the work feels without exposing themselves to hazards of moving construction equipment,” he said.

|

Level 1, Virtual Twin: a physically accurate digital representation Level 2, Connected Twin: integrates real-time data to provide performance insight Level 3, Predictive Twin: leverages data to predict outcomes Level 4, Prescriptive Twin: leverages modeling and real-time simulation for future scenarios Level 5, Autonomous Twin: uses multiple real-time data feeds to learn and make decisions to correct issues automatically |

Future is virtual

Plant-Directed Research and Development is developing digital twins at various scales, and the investment is also helping to create tools for other projects. “Digital twins are tools. They are a simulation at some level to help you solve some problem, such as improving the capacity and reliability of a machine,” said Couture.

While a “true” digital twin is a simulator, Stowe noted that not all projects need the full simulator because different projects require different levels of connectivity and realism.

“There are applications across the maturation continuum (see sidebar),” Stowe said. This continuum allows digital twin technology to be beneficial across a variety of projects with differing needs.

“Digital twin technology really has something for everyone—engineers, data scientists, procedure writers,” said Stowe. “The technology applies to and can inform many, many jobs and facilitate decision making.”

Take 5 minutes to learn about Brent Wright., of Y-12 Production Operations. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Sometimes when people are asked how they are doing, their response is a sarcastic “I’m living the dream.” However, for Brent Wright, that response would be sincere.

“I have to pinch myself that I get to do what I do,” he said. In his current role, Brent oversees several major capability areas, including Assembly Disassembly Operations, Special Materials Operations, SNMO, Fabrication Operations, and Enriched Uranium Operations.

He has been at Y-12 for almost 23 years and came to the site shortly after graduating from the University of Tennessee in Knoxville.

“The commitment of the people in this valley I’ve seen over the past 23 years is the most impressive aspect of the job,” he said. “There are a lot of challenges, with an aging infrastructure and aging equipment. We constantly overcome these challenges. I think what drives us to do this is that desire to meet the mission. To be a part of that, there is no greater satisfaction. I’m blessed to go to a job that matters to our nation.”

For Wright, what stands out the most is not just employees’ commitment to the mission but also their commitment to Y-12 itself.

“There are people who have spent 40+ years at Y-12,” he said. “That just isn’t the norm outside of the valley. Once you are introduced to this industry, to the magnitude of the scope, the commitment is contagious. I get up in the mornings and go to a place that is helping to secure the nation’s and our allies’ freedom and security. I can’t see myself doing anything else at this point.”

Are you doing what you envisioned as a young adult? If so, describe how you got here.

I couldn’t have envisioned being in this business, but becoming an engineer was natural for me. I always liked to solve problems and work in a team environment. I was raised by a chemical operator that taught me the value of working with all levels of the organization…most importantly, with the people who perform the tasks on a daily basis. They are the ones who understand the processes and the complex tasks performed here.

What is your favorite aspect about your work environment? How does that aspect make you know the mission is being met?

Our capacity to do all the things we do throughout the facility, given all of the constraints we have to work through. Even with all the strict standards and regulations, we are still able to meet mission numbers. That’s pretty impressive. I attribute the success to the team environment and the people that we have at Y-12.

What’s your favorite outside-of-work activity and why?

Enjoying baseball with my sons. I played baseball in school, and now, I get to watch them do it. I’m glad they’re playing because baseball is a great sport that teaches teamwork, respect for authority, and how to face success and failure. Baseball is a great teacher of life. I’ve had the opportunity to coach baseball for the last 20 years, and I really enjoy working with young adults to hopefully make an impact on not just their baseball future but their lives.

What tools do you use and reference to keep current on changes to your skillset?

I have a small group of mentors who have challenged me over the past 23 years. Each of them has a different perspective and different skills that push me to improve. Those different viewpoints make you feel uncomfortable. When I have the opportunity to mentor employees, I often tell them to stay uncomfortable––that is where growth happens. I tell them to surround yourself with people who will be honest with you and challenge your weaknesses and encourage your strengths.

Nick D. and Kiki R. are wrapping up their 10-week stint at Y-12

Some problems encountered at Y‑12 require a broader perspective, like paying better attention to the details of business models, administrative procedures, and statistical trends. While many engineers and scientists learn principles and then apply them to technical problems, data analysts who apply statistical principles to business problems can offer a new perspective. That is where the Graduate Assistantship Program, also known as GAP, comes in. In partnership with the University of Tennessee, Y‑12 has a contract in place where students enrolled in the Haslam College of Business master of business administration (MBA) program participate in a fellowship at the site.

Nick D. and Kiki R. are wrapping up their 10‑week stint at Y‑12 (they will complete the fellowship in the fall semester by working several hours each week). The two share similar backgrounds in that they were college athletes (Nick for University of Delaware football and Kiki for University of Tennessee softball), and both will graduate in December with MBAs. The pair shared their perspectives on the GAP, acknowledging that they accepted the fellowship without knowing a lot about the Y‑12 mission but are taking away valuable lessons learned.

“I was not expecting to find the community of family I found here,” Kiki said. “Everyone wants to help you move forward in what you’re doing.”

Nick agreed. “It’s a family‑like atmosphere. There is very serious work going on at the site, but everyone is open to helping you.”

Nick is working with Jim H. in Y‑12 Technical Assurance to apply analytical skills to Y‑12 Production. “Jim offers a wealth of knowledge… Working with him is like drinking from a fire hose,” joked Nick in terms of the variety of information he is gaining.

“Nick and Kiki brought what any prospective employer would want: an insatiable appetite for learning, a different perspective, and a great attitude,” said Jim. “They brought insight and creativity to a variety of projects, ranging from fissile material handler training to artificial intelligence, but their greatest contribution by far was in how they shattered my preconceptions!”

Kiki, who is working with Jacob S. in the Production Activities Training group, shared that her time at Y‑12 has been filled with leadership experience opportunities.

Jacob said, “Kiki has been a valuable addition to the Production Activities Training team. She revamped our SharePoint site, resulting in a streamlined and more efficient platform that enabled an easier interface for all users. She has also brought unique leadership experience as a D1 athlete and facilitated a forum to share her perspective on leadership with our entire team.”

Working at a government facility wasn’t something either student had considered. “There are good opportunities in most areas — even if it is an area where we normally wouldn’t have thought we would have joined,” Kiki said. “Stepping into these new areas opens our minds to new doors. It’s good to have different experiences as well as a variety of references and contacts.”

Nick said he had an idea of what he wanted to do next as part of his MBA education, but a fellowship at Y‑12 wasn’t what that idea originally looked like. “I’m glad I stepped outside the box of my ‘plan.’ I’ve appreciated the journey and connections I’ve made. The experiences have been valuable.”

Ashley H., former program manager for University and Industry Partnerships, said, “These fellowships are subcontracts we have with UT, giving the fellows opportunities a traditional intern might not have. It is important for leadership to support this program and continue bringing GAP students to Y‑12. Their presence gives us opportunities to bring in students who may not be considered otherwise [because their expertise is in a different or non‑STEM discipline].” Ashley left CNS August 15 to pursue other opportunities, but she hopes to see continued opportunities and success from the programs and students as they continue to grow. “My mission for outreach and mentorship is part of my core values, regardless of where I work,” she added.

Jacob stated that Y‑12 is moving into a new era, with a large percentage of the site population nearing retirement. “In the near future, we have the start‑up of the Uranium Processing Facility and Lithium Processing Facility; it is paramount that we [Y‑12] do not miss an opportunity to hire great candidates to support our mission, regardless of their area of study.”

According to Jacob, having an MBA student on the team reenforced the importance of the new Y‑12 GOLD program (Growth, Opportunity, Leadership, and Development — a site leadership development program). “Y‑12 must continue to develop well‑rounded leaders. Kiki’s innate ability to lead was impressive. Having no knowledge of our facilities or processes, she quickly adapted and was able to create positive change in our organization almost immediately.”

Jim said that the pair challenged his own way of thinking. “I had a very narrow notion of the skillsets I thought were ideal [for job placement], but Nick and Kiki’s intelligent and articulate engagement in every discussion made me realize that I must broaden the qualities of an ‘ideal’ candidate.”

Both Nick and Kiki were complimentary when asked about the GAP. “Go into the program with an open mind — even if it’s not something you think you would do,” she said.

“You’ll be surprised what you will learn,” Nick added.

Take 5 minutes to learn about Eric G., a welder at the Uranium Processing Facility. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Since 1952, the Ingalls Apprentice School has provided the Navy shipbuilding industry more than 4,000 graduates. One of those graduates is Eric G., a quietly confident, seasoned welder at Y‑12’s UPF site.

Eric enrolled in welding school at the age of 19 and began his career in Virginia, building aircraft carriers and honing his skills to build the nation’s most powerful defense ships.

“I have worked on several aircraft carriers in my life, and knowing that what I’ve built has provided security to the men and women on them has been an honor,” he said.

Now, the 61‑year-old is using his career knowledge and experience in welding, steelworking, boilermaking, and electrical work in his current role as an electrical welder at UPF. This brings his profession full‑circle while keeping the mission of national security as his constant North Star.

“I believe in our national security,” Eric said. “I know how critical this project is. You come here and see what’s going on and you feel like life is truly a circle.”

Eric is a self‑proclaimed “family man,” speaking proudly about his children and grandchildren, as well as his extended family who served in the military. “Everything has a purpose, and if you’ve got military family members, like I have, I feel like I am doing my part for their safety and security.”

Why are you mission success?

“I believe in our national security. I can see the big picture and I work hard to get the job done.”

What is the greatest strength you bring to your organization?

“I am a self‑starter. I stay busy by learning the things I don’t know, so I can be of greater help to the project. Because I have been on the side of building the subs, I can see the whole picture of what we are doing here and understand what that means to our national security.”

Why is teamwork an important aspect when working at Y‑12?

“Teamwork is very important. You have to have a common goal and the right chemistry on a team. Otherwise, you won’t get anything done.”

What stands out to you about UPF?

“They go above and beyond to make sure it’s safe. You are able to see the project take shape and it is neat to see the progress. It is hard work though.”

All Pantex and Y-12 employees have a story about how they got to CNS, but only a few can say the journey included working with a sitting U.S. president. Eight employees who had that experience shared the similarities between the two entities and detailed their duties with the commanders-in-chief.

Garcia B.

Garcia worked for the White House Communications Agency (WHCA) during three presidential terms: Obama, Trump, and Biden. As part of the communications team, he was an audiovisual technician and White House Television (WHTV) director.

Garcia said his White House experience prepared him well for his latest role at Pantex. “Being at the White House allowed me to work with people from a variety of backgrounds with varying personalities, ranging from senior staff members to interns to foreign dignitaries. Learning how to communicate effectively with personnel enabled me to adapt to the different personalities in the civilian sector,” he said.

Jeff C.

President George W. Bush was commander in chief during Jeff’s tenure as a member of the Marine Helicopter Squadron One (HMX-1), commonly known as the Presidential Helicopter Squadron.

“I served as the quality assurance (QA) chief and trip leader, where I led the QA division that ensured that HMX-1 executive flight detachment assets for presidential/chief executive and White House transport were properly inspected and maintained for maximum safety and on-call availability with a 100% mission success rate,” he said.

Jeff’s time with the squadron helped prepare him for his work at Y-12 as an engineering advisor.

“The high level of responsibility I was accustomed to for ensuring the safety and mission success of presidential support missions made transitioning into a nuclear environment much easier,” he said.

Linda F.

Linda began her career in the White House when she was 19 as a member of the White House Office of Presidential Correspondence. After 3 years, she moved to the Office of Administration and served as the administrative assistant to the deputy director of administration in the West Wing, along with President Ronald Reagan’s senior staff.

Linda said her time at the White House “was an exciting job” and instilled a very strong work ethic in her at a young age, which she’s still grateful for. “Every day brought new challenges and new solutions,” she said. “Anyone working there tried to do their very best every single day.”

She still uses the same work ethic she developed from her time at the White House as she faces new challenges every day in helping to maintain all the equipment and facilities at Y-12.

Brenda G.

Brenda also worked for WHTV. She flew on Air Force One (AF-1) during President Obama’s tenure and was tasked with recording any briefings the president might give.

“WHCA prepared me for this role [at Y-12] by perfecting my attention to detail and organization skills. There were zero errors allowed at WHCA. The world has to see and hear the president without incident. I had to ensure the right people got to the right place at the right time in order for this to happen,” she said. “At CNS, it’s the same principles and work ethic: doing the task the right way, the right time, every time.”

Joe H.

There are not many CNS employees who can say they ate chocolate chip cookies baked by Nancy Reagan, wife of President Ronald Reagan. However, Joe can make that claim, as it is one of his fondest memories working with the Reagan/George H. W. Bush administration during his time with the WHCA from 1984 to 1988.

“It was a special duty to get assigned to WHCA,” Joe said. ““I was in my early 20s, so all of this was really cool to me. I got to travel the world and work at the White House — way cool!”

Joe noted that President Reagan was just like “one of us.” There was no Wi-Fi or internet connection during this time, so Reagan enjoyed simple pleasures like walking or riding horseback on his ranch and trimming trees.

“Whether you’re military, a federal employee, or a contractor, we are all serving a greater mission,” Joe said. Pantex and Y-12 call upon employees who are dedicated to the values of supporting our nation in order to meet our nuclear deterrent mission. To Joe, that is precisely the similarity between working with a president/at the White House and for CNS — the sense of duty to support a higher calling.

Greg K.

Greg worked with the Trump and Biden administrations as part of the Presidential Support Squadron, Air Force Security Forces.

“My role was to provide direction and guidance to the Security Forces personnel and ensure the safety and security of Air Force One and its support complex,” he said.

Greg came to Pantex through the DOD SkillBridge Program.

“My previous role prepared me to work at Pantex by allowing me to understand the importance of national security, from the lowest to highest level, and has allowed me to understand Pantex’s role in ensuring the safety of the nation,” he said.

Matt P.

Matt worked at the White House during the George W. Bush and Obama administrations. He was on the travel advance team, setting up and running events globally.

“I would travel anywhere from 1 week to 3 weeks in advance of the president to coordinate and set up event sites, including sound amplification, media displays, staging, lighting, national television and radio press feeds, the president’s podium and presidential seal,” he said.

Matt also came to Y-12 through the DOD SkillBridge Program.

“The tenets of ‘A Learning Organization’ are just as applicable. ‘Set High Standards’ is one that sticks out to me,” he said. “We had a standard at the White House called ‘Presidential Quality.’ It is the best of everything, and it was the lowest standard everyone had to meet. Anything less was a failure.”

Michael V.

Michael worked as a uniformed officer with the U.S. Secret Service, where he controlled and maintained access and security for the White House, the Treasury Department, the Eisenhower Executive Office Building, and the New Executive Office Building during President Trump’s administration.

He said, “The Secret Service prepared me for Y-12 by training me to control access and maintain security. I think Y-12 and the White House are pretty comparable as far as the job goes that I perform.”