Y-12 Blog

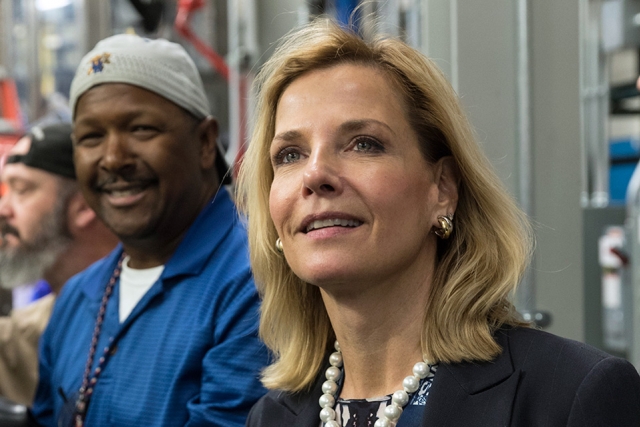

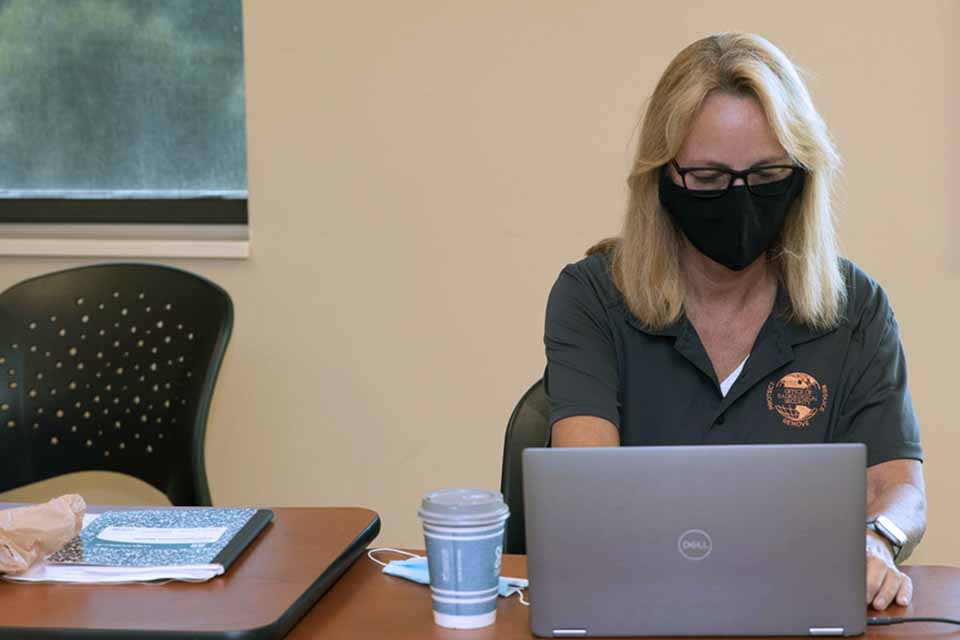

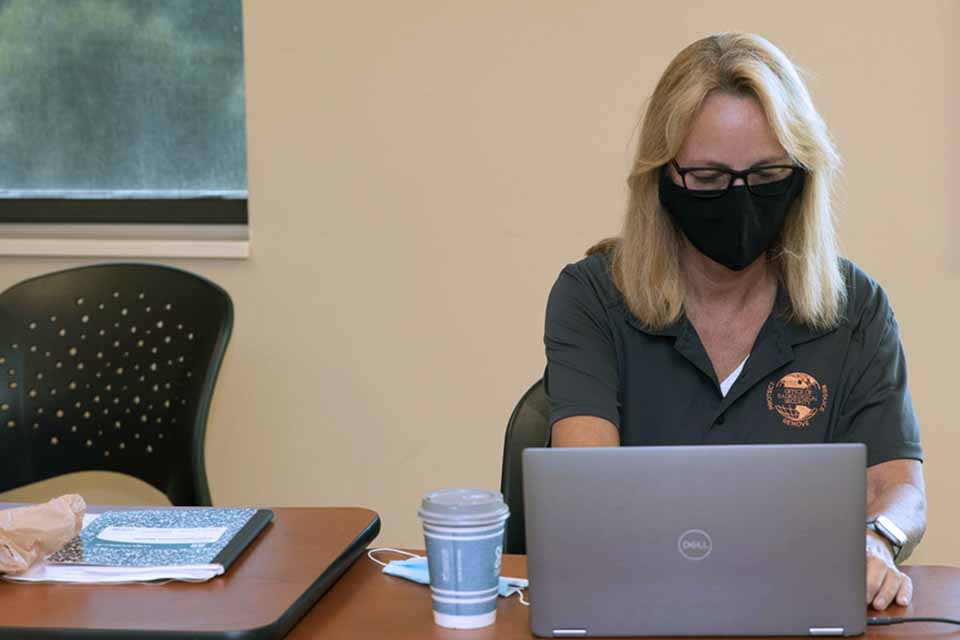

Julie Cramer started at Y‑12 in 2010 as an intern and has held several positions at the site during her career. (Photo by Jordan Ray.)

Julie Cramer started at Y‑12 in 2010 as an intern and has held several positions at the site during her career. (Photo by Jordan Ray.)

A key principle at Y‑12 is continuous improvement — one of 11 principles that reflect the site’s commitment to being a learning organization. Twice a year, the Performance Improvement group asks Y‑12 organizations to submit projects to be included in its “Continuous Improvement Celebration.” There, each team shares its successes, and employees vote for the Best Y‑12 Initiative and Best Value Stream Element Teams Initiative.

This year’s recent celebration included 14 projects — 10 Y‑12 initiatives and 4 VSET initiatives.

A key principle at Y‑12 is continuous improvement — one of 11 principles that reflect the site’s commitment to being a learning organization. Twice a year, the Performance Improvement group asks Y‑12 organizations to submit projects to be included in its “Continuous Improvement Celebration.” There, each team shares its successes, and employees vote for the Best Y‑12 Initiative and Best Value Stream Element Teams Initiative.

This year’s recent celebration included 14 projects — 10 Y‑12 initiatives and 4 VSET initiatives.

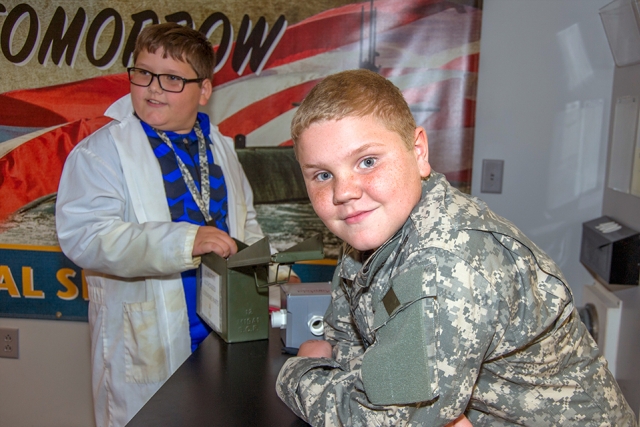

The Y‑12 National Security Complex places trainees in fully immersive virtual environments with next‑generation technologies.

The Y‑12 National Security Complex places trainees in fully immersive virtual environments with next‑generation technologies.

Terra M. is a night shift carpenter on the UPF Project and is one of many traveling craft professionals working at the site.

The road less traveled has proven to be a path to leadership for Terra M.

Terra M. is a night shift carpenter on the UPF Project and is one of many traveling craft professionals working at the site.

The road less traveled has proven to be a path to leadership for Terra M.

Field Engineering Administrator Kaitlyn W. shares her thoughts on teamwork as part of a series of Y‑12 stories highlighting our Construction team.

Field Engineering Administrator Kaitlyn W. shares her thoughts on teamwork as part of a series of Y‑12 stories highlighting our Construction team.

Field Engineering Administrator Kaitlyn W. shares her thoughts on teamwork as part of a series of Y‑12 stories highlighting our Construction team.

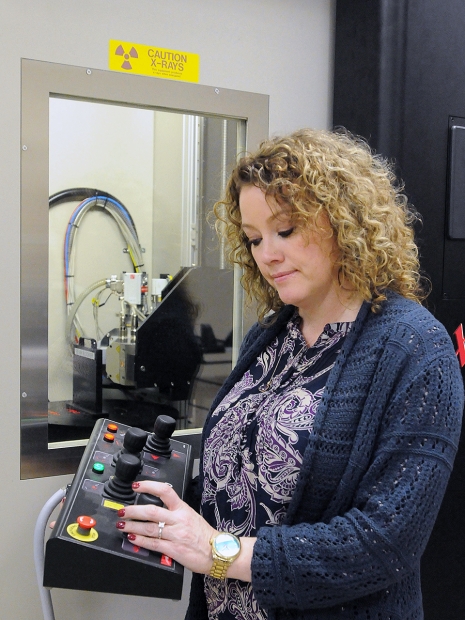

Leslie M. is set to take on her newest challenge at Y‑12. Photo by Brian Holt.

Leslie M. is set to take on her newest challenge at Y‑12. Photo by Brian Holt.

Leslie M. is set to take on her newest challenge at Y‑12. Photo by Brian Holt.

Eric H. began his Y‑12 career as a chemical operator in 2001, fresh out of community college.

Eric H. began his Y‑12 career as a chemical operator in 2001, fresh out of community college.

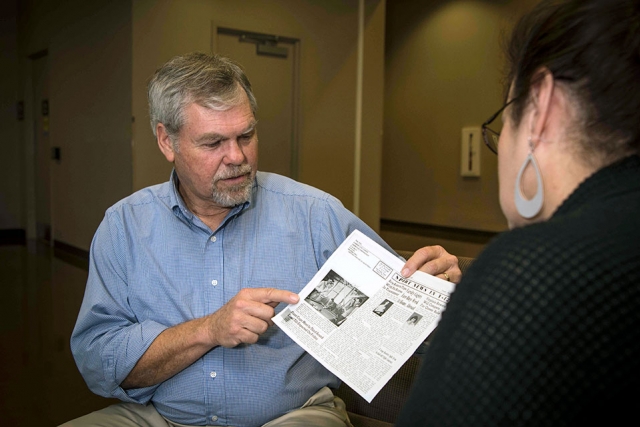

Matthew S. reflects on being in the same Protective Force as his Mamaw 80 years later.

Matthew S. reflects on being in the same Protective Force as his Mamaw 80 years later.

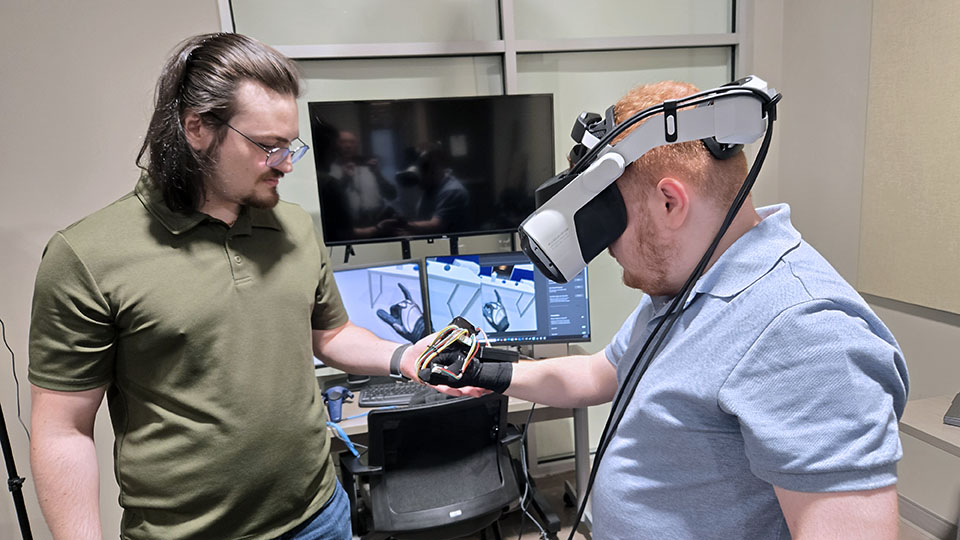

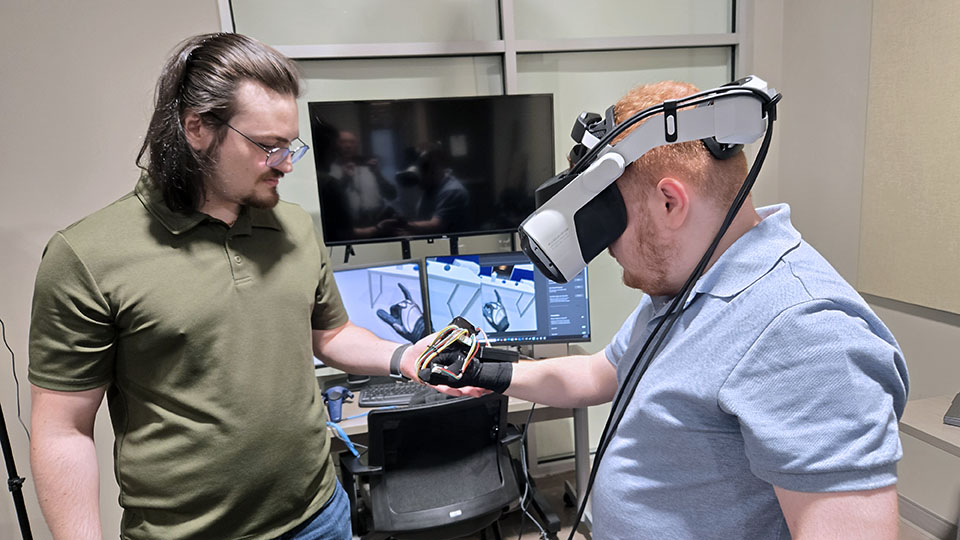

FIU graduate students Julian Guerra (L) and Brad Alvarez manipulate a haptic glove

FIU graduate students Julian Guerra (L) and Brad Alvarez manipulate a haptic glove

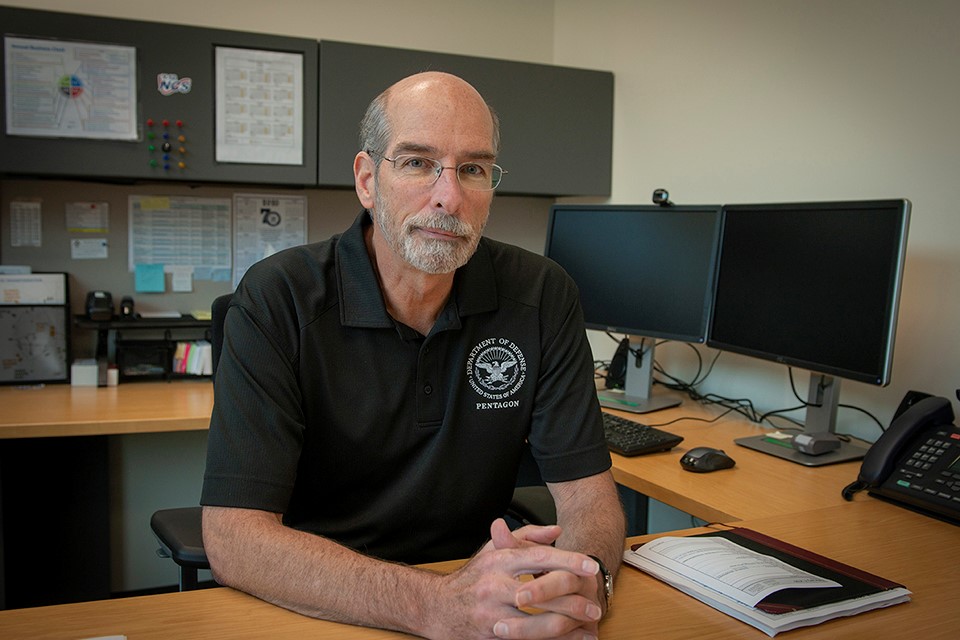

After almost 30 years of military service and a stint at Pantex, Chris Burns is now ready to serve at Y-12. Photo by Matthew Harkins.

After almost 30 years of military service and a stint at Pantex, Chris Burns is now ready to serve at Y-12. Photo by Matthew Harkins.

After almost 30 years of military service and a stint at Pantex, Chris Burns is now ready to serve at Y-12. Photo by Matthew Harkins.

After 20+ years at Pantex, Josh Gerken is ready to make Y-12 his work home. Photo by Joy Kimbrough.

After 20+ years at Pantex, Josh Gerken is ready to make Y-12 his work home. Photo by Joy Kimbrough.

Meet Jon Ragan who is a new member of the Business Management and Transformation leadership team. Photo by Jordan Ray.

Meet Jon Ragan who is a new member of the Business Management and Transformation leadership team. Photo by Jordan Ray.

Daniel Riddick, Y‑12 Technology Transfer program manager, engaged with potential partners at NNSA’s Innovation Day in Arlington, VA.

Daniel Riddick, Y‑12 Technology Transfer program manager, engaged with potential partners at NNSA’s Innovation Day in Arlington, VA.

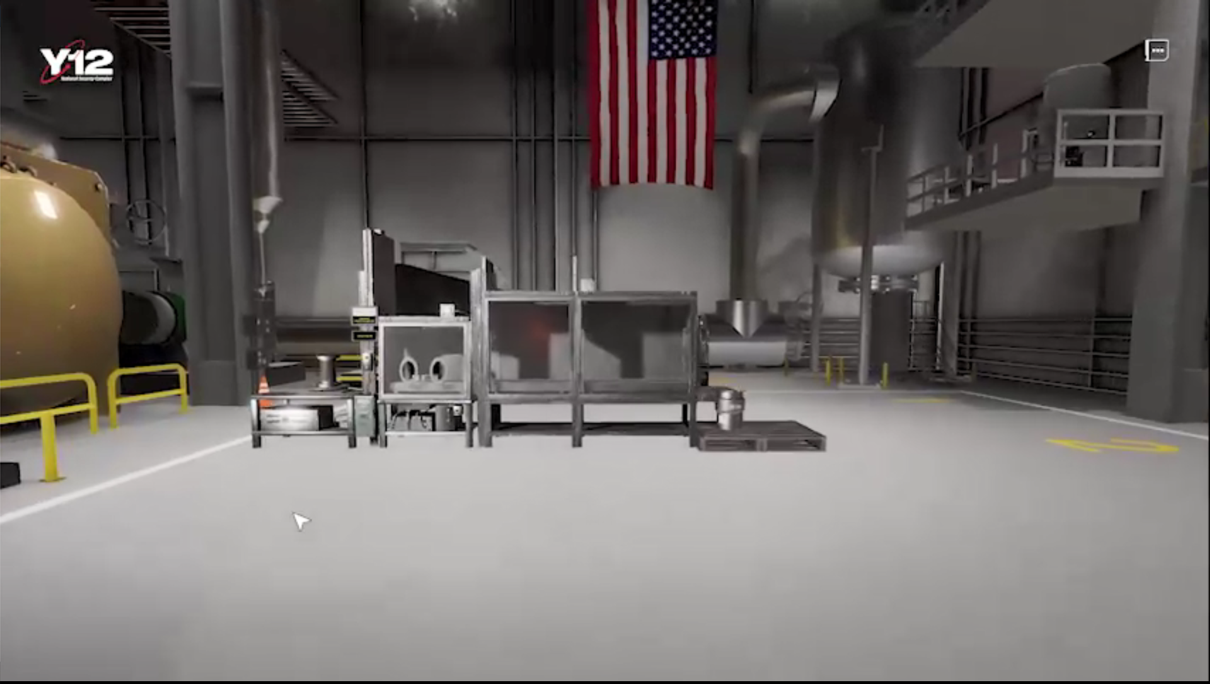

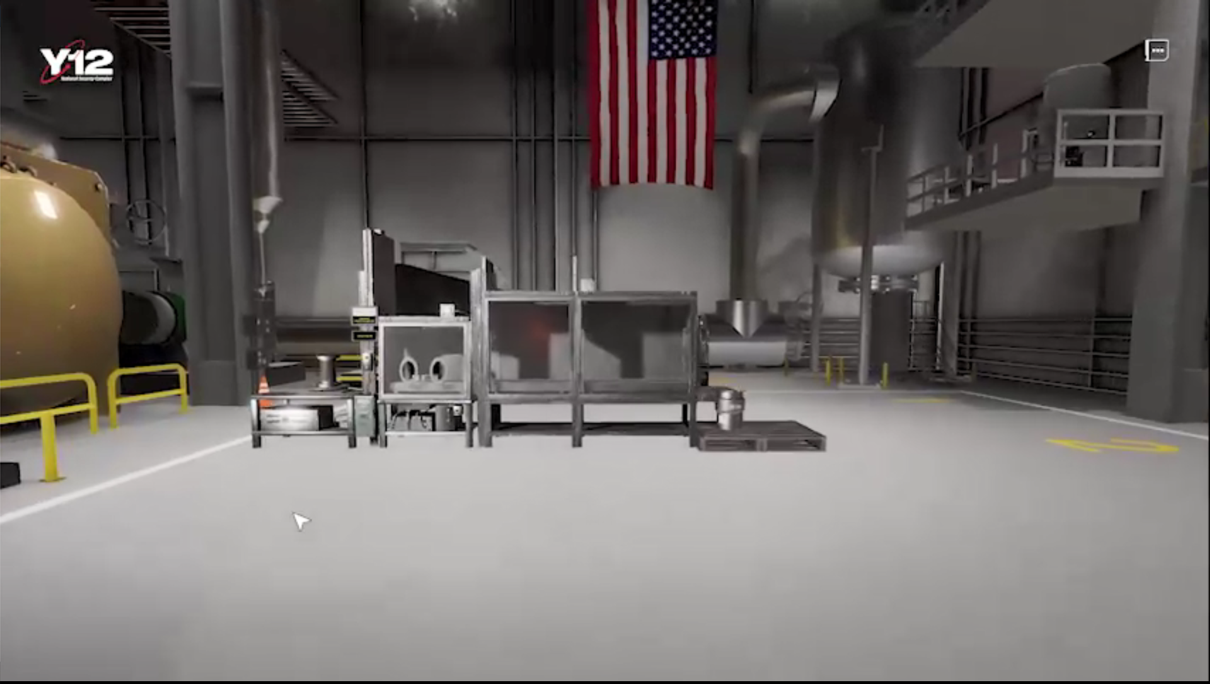

A representation of a glovebox within a digital twin allows operators to practice operations virtually before working with actual materials.

A representation of a glovebox within a digital twin allows operators to practice operations virtually before working with actual materials.

Take 5 minutes to learn about Brent Wright., of Y-12 Production Operations. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Sometimes when people are asked how they are doing, their response is a sarcastic “I’m living the dream.” However, for Brent Wright, that response would be sincere.

Take 5 minutes to learn about Brent Wright., of Y-12 Production Operations. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Sometimes when people are asked how they are doing, their response is a sarcastic “I’m living the dream.” However, for Brent Wright, that response would be sincere.

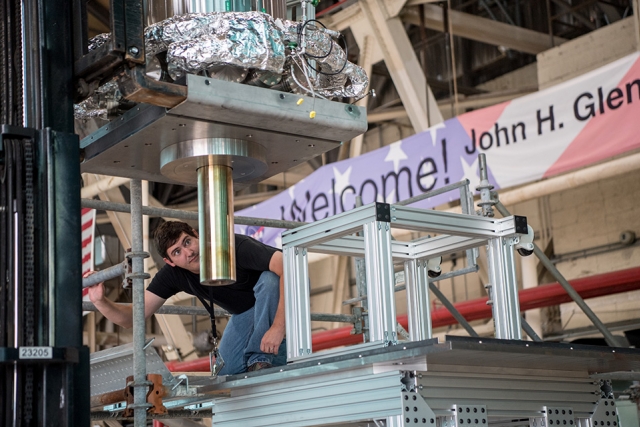

Nick D. and Kiki R. are wrapping up their 10-week stint at Y-12

Nick D. and Kiki R. are wrapping up their 10-week stint at Y-12

Take 5 minutes to learn about Eric G., a welder at the Uranium Processing Facility. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Take 5 minutes to learn about Eric G., a welder at the Uranium Processing Facility. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

All Pantex and Y-12 employees have a story about how they got to CNS, but only a few can say the journey included working with a sitting U.S. president. Eight employees who had that experience shared the similarities between the two entities and detailed their duties with the commanders-in-chief.

All Pantex and Y-12 employees have a story about how they got to CNS, but only a few can say the journey included working with a sitting U.S. president. Eight employees who had that experience shared the similarities between the two entities and detailed their duties with the commanders-in-chief.

Take 5 minutes to learn about Christian G., of Production Integration. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Christian G. came to Tennessee in 2023 with his family and little more than “hopes and dreams.”

Take 5 minutes to learn about Christian G., of Production Integration. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Christian G. came to Tennessee in 2023 with his family and little more than “hopes and dreams.”

Take 5 minutes to learn about Brandi Reagan, recruiter for Mission Engineering. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Take 5 minutes to learn about Brandi Reagan, recruiter for Mission Engineering. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Take 5 minutes to learn about Sean L., Y-12 Nuclear Maintenance Services director. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Sean L. brings experience as both an engineer and a naval officer to his job at Y-12.

Unlike for some people, Mondays don’t get him down.

Take 5 minutes to learn about Sean L., Y-12 Nuclear Maintenance Services director. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Sean L. brings experience as both an engineer and a naval officer to his job at Y-12.

Unlike for some people, Mondays don’t get him down.

Y‑12’s innovative and safer low temperature method for yielding lithium has the potential to change current methodologies.

Y‑12’s innovative and safer low temperature method for yielding lithium has the potential to change current methodologies.

Jovon H. interned at Y-12 in the summer of 2023 and is now working in Y-12 Infrastructure.

Jovon H. interned at Y-12 in the summer of 2023 and is now working in Y-12 Infrastructure.

Y-12er father and son, Tim and Zach, love that they have a shared mission at work.

June is the month to celebrate the fathers in our lives. Some lucky employees have the privilege of working with their fathers on‑site.

Meet Y-12ers Tim and Zach H., father and son.

Y-12er father and son, Tim and Zach, love that they have a shared mission at work.

June is the month to celebrate the fathers in our lives. Some lucky employees have the privilege of working with their fathers on‑site.

Meet Y-12ers Tim and Zach H., father and son.

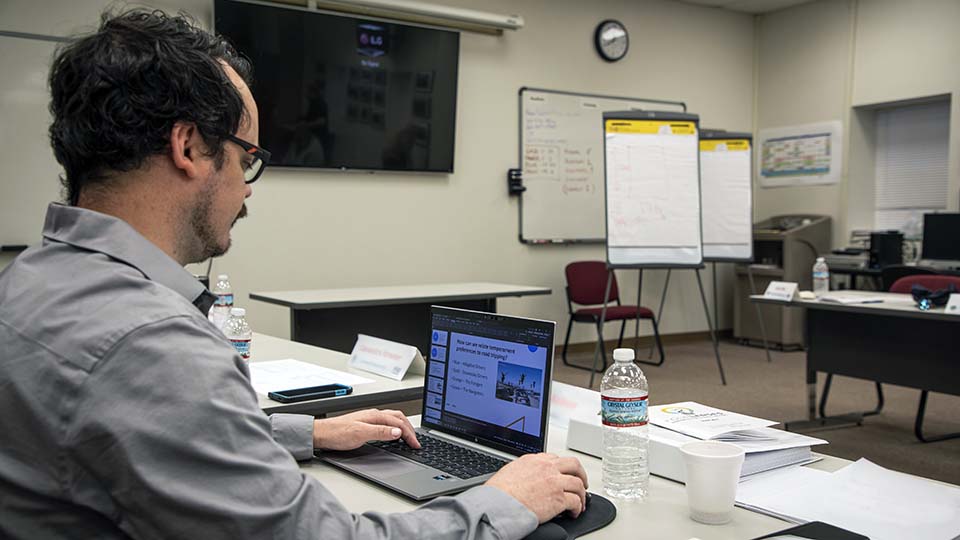

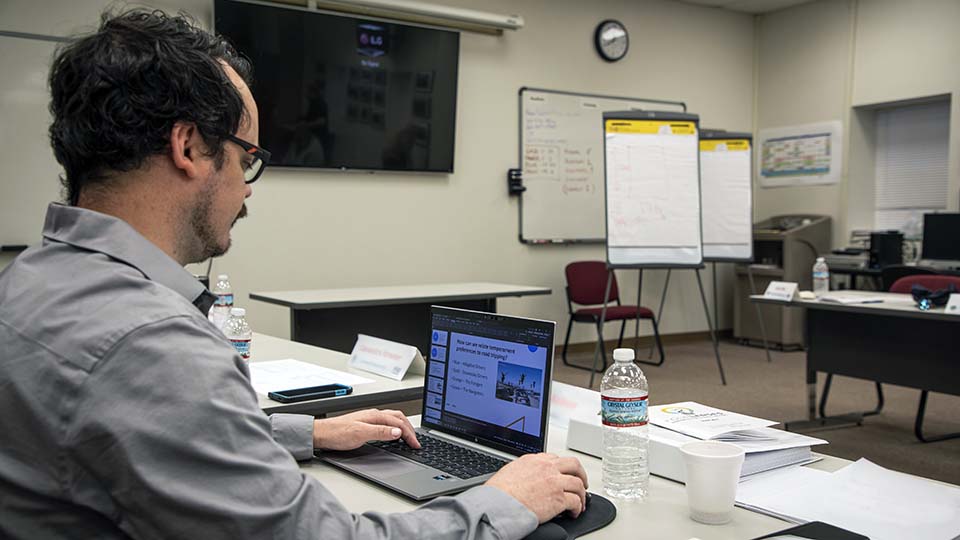

Wireless technology has made its way to the Central Training Facility (CTF), creating a more efficient learning environment for security police officers.

Wireless technology has made its way to the Central Training Facility (CTF), creating a more efficient learning environment for security police officers.

.Celebrating Armed Forces Day

.Celebrating Armed Forces Day

May is the month to celebrate the mothers in our lives. Some lucky employees even have the privilege of working with their mothers on-site.

Meet Y-12er mother and son, Patty and Bryson B.

May is the month to celebrate the mothers in our lives. Some lucky employees even have the privilege of working with their mothers on-site.

Meet Y-12er mother and son, Patty and Bryson B.

Y‑12 Career ONE Manager Kody C. (far right) with the latest class, which boasts 19 recent engineering graduates.

Consumers may test drive a few cars before they find the right one. At Pantex and Y‑12, Career ONE participants take a similar approach to find the right job.

Y‑12 Career ONE Manager Kody C. (far right) with the latest class, which boasts 19 recent engineering graduates.

Consumers may test drive a few cars before they find the right one. At Pantex and Y‑12, Career ONE participants take a similar approach to find the right job.

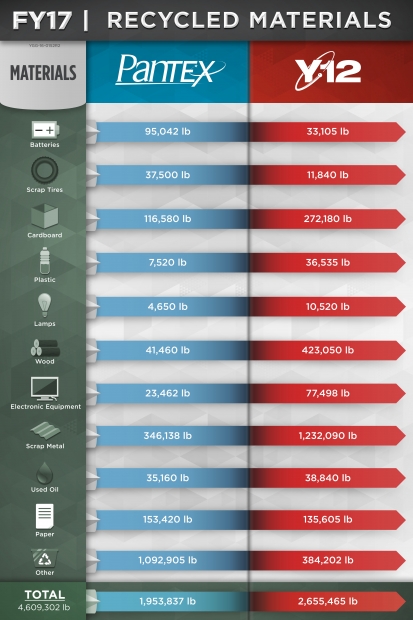

Celebrated annually on November 15, America Recycles Day, also known as National Recycling Day, began in 1994. The day serves to raise awareness about recycling and the purchasing of recycled products. It’s a reminder to all that how we recycle and reuse products is important.

Celebrated annually on November 15, America Recycles Day, also known as National Recycling Day, began in 1994. The day serves to raise awareness about recycling and the purchasing of recycled products. It’s a reminder to all that how we recycle and reuse products is important.

Take 5 minutes to learn about Chris Harkins, CNS chief operating officer. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Take 5 minutes to learn about Chris Harkins, CNS chief operating officer. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

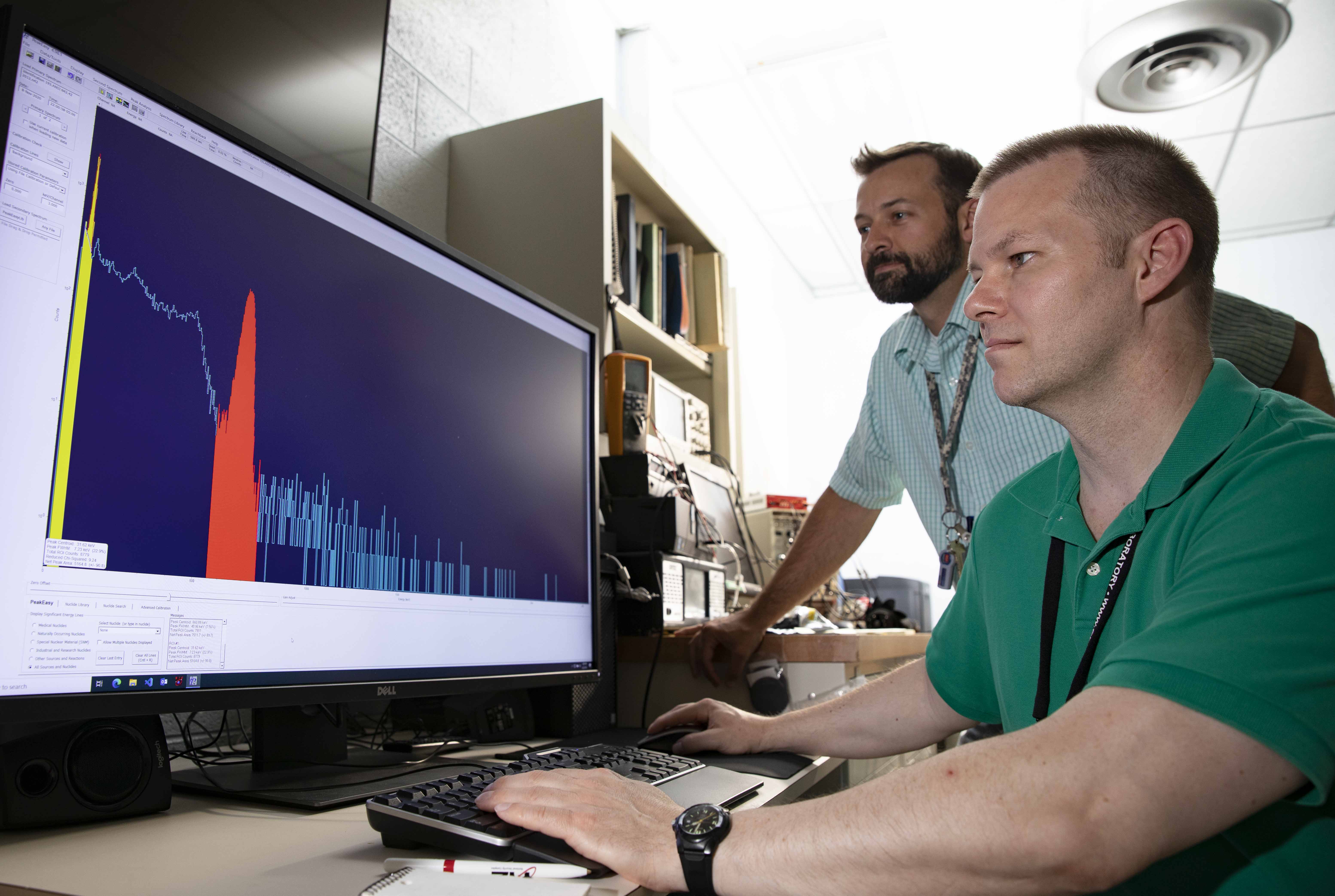

Radiation is all around us. The sun, the earth, and other sources all emit radiation. At Y‑12 National Security Complex, radiation exposures are equivalent to what you get from nature.

Radiation is all around us. The sun, the earth, and other sources all emit radiation. At Y‑12 National Security Complex, radiation exposures are equivalent to what you get from nature.

At Y-12 National Security Complex, the landscape continues to transform. The latest new facility to begin operations is a state-of-the-art fire station.

At Y-12 National Security Complex, the landscape continues to transform. The latest new facility to begin operations is a state-of-the-art fire station.

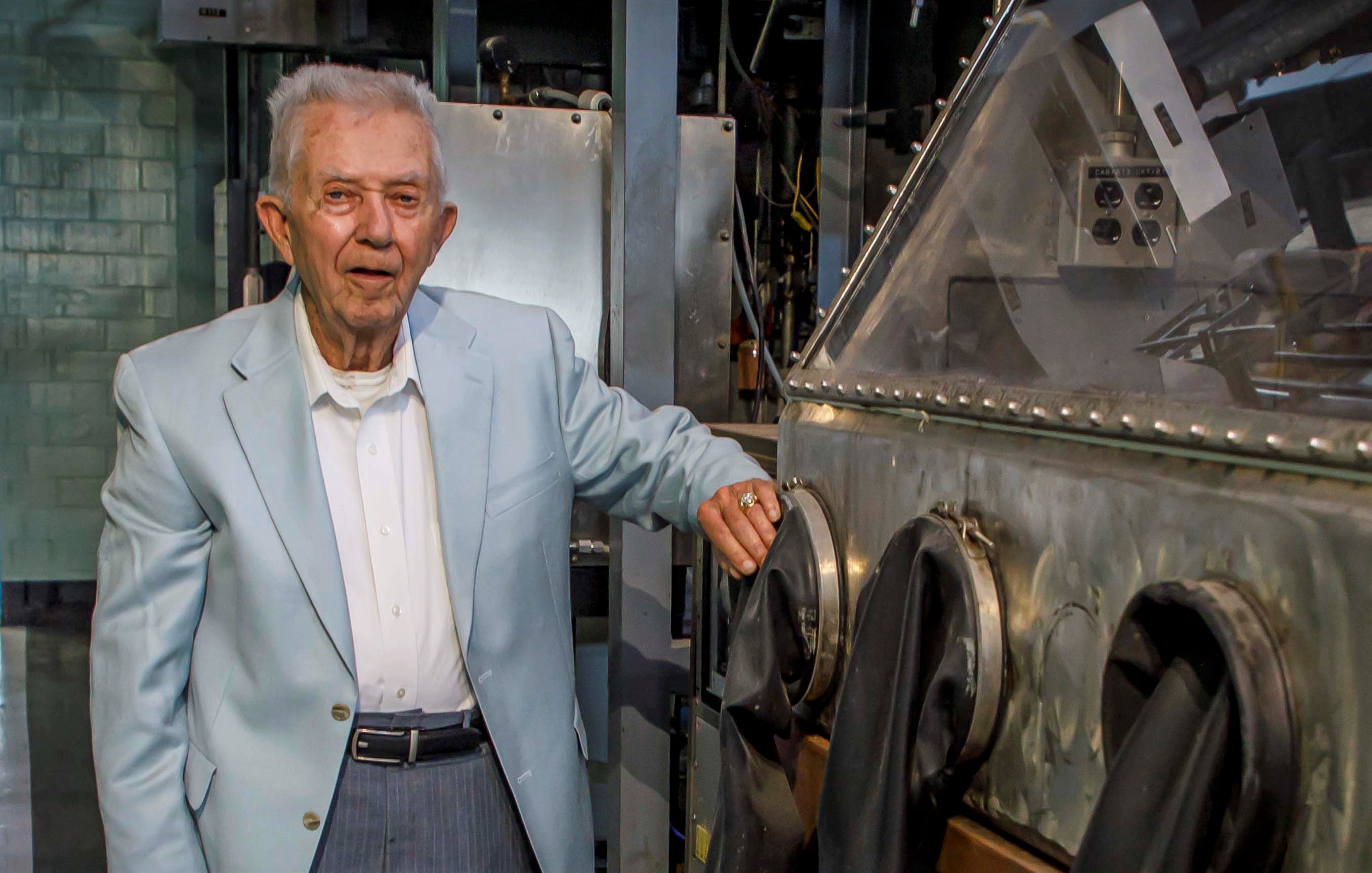

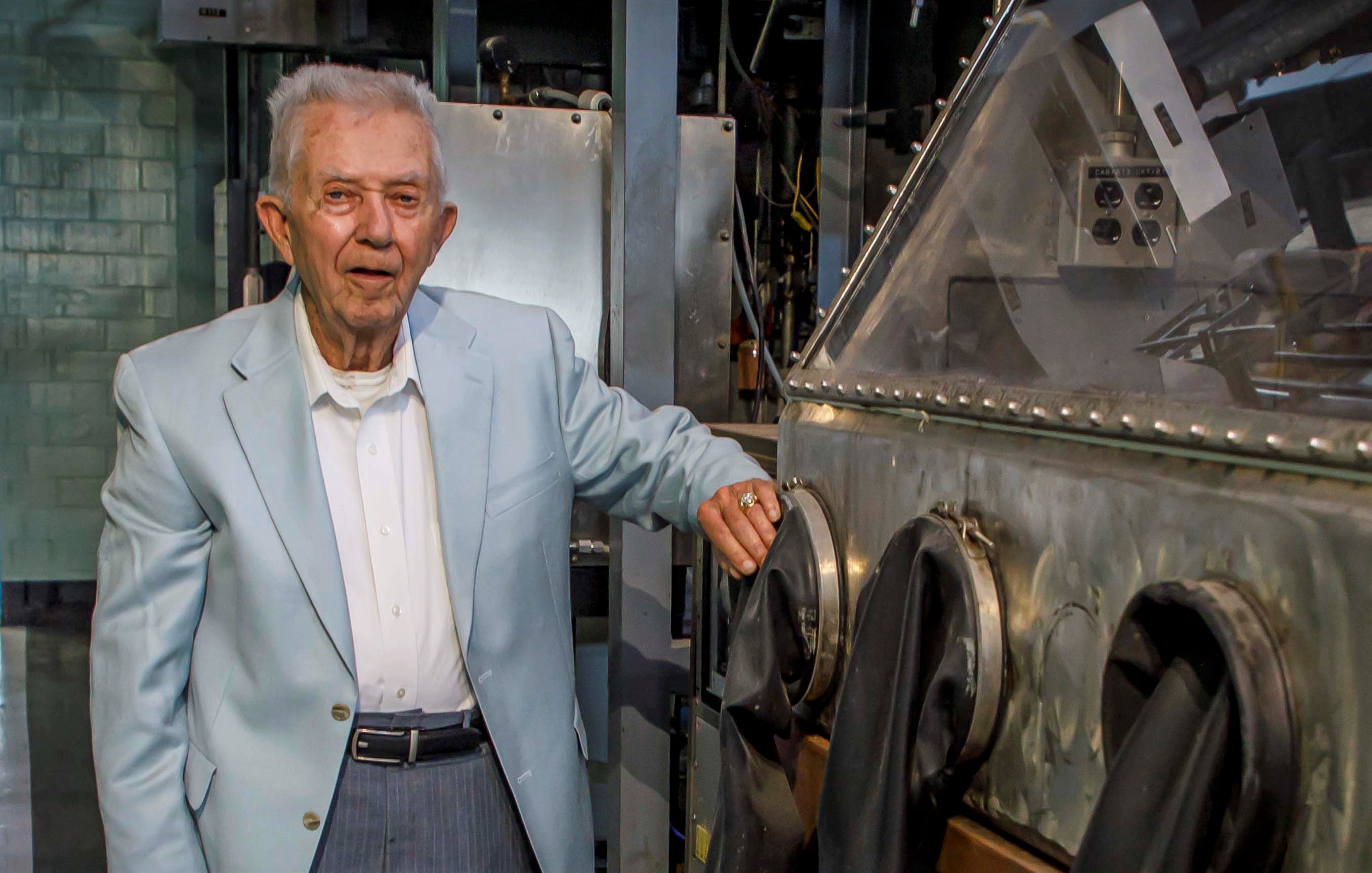

Bill Clark poses next to a glove box similar to one he worked with in the 1950’s

Bill Clark poses next to a glove box similar to one he worked with in the 1950’s

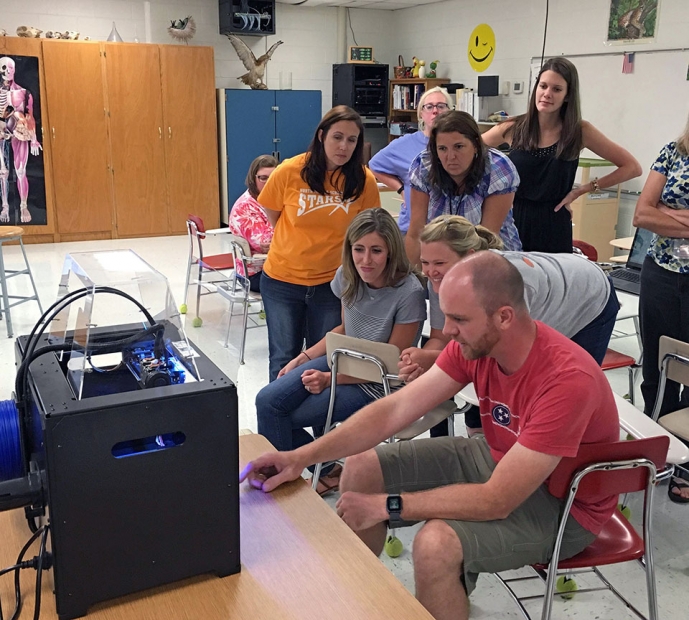

Jeff Hankins (center) now calls nearly two dozen of his former students coworkers.

Jeff Hankins (center) now calls nearly two dozen of his former students coworkers.

Duty. Honor. Country. It is a theme in David Turner’s life. From achieving Eagle Scout status as a young man to a 35-year military career concluding as a highly decorated retired brigadier general, Turner’s goals often derive from his desire to lead and serve.

Duty. Honor. Country. It is a theme in David Turner’s life. From achieving Eagle Scout status as a young man to a 35-year military career concluding as a highly decorated retired brigadier general, Turner’s goals often derive from his desire to lead and serve.

Jonathan Fleury, a section manager in Fabrication at Y-12, began his site tenure in an apprenticeship program, one gateway to a career at Pantex or Y-12.

Jonathan Fleury, a section manager in Fabrication at Y-12, began his site tenure in an apprenticeship program, one gateway to a career at Pantex or Y-12.

Chafin H. pulls double duty when it comes to serving others; he works at Pantex and is a lieutenant colonel (select) in the U.S. Air Force Reserve.

Once a month, Chafin H. loads up his Suburban and points the truck north toward Colorado Springs.

Chafin H. pulls double duty when it comes to serving others; he works at Pantex and is a lieutenant colonel (select) in the U.S. Air Force Reserve.

Once a month, Chafin H. loads up his Suburban and points the truck north toward Colorado Springs.

The HEUMF Connector (HCON) will connect HEUMF and UPF, providing a more efficient way to transport production material between the two facilities.

The HEUMF Connector (HCON) will connect HEUMF and UPF, providing a more efficient way to transport production material between the two facilities.

The HEUMF Connector (HCON) will connect HEUMF and UPF, providing a more efficient way to transport production material between the two facilities.

A new scale, left, is now about 10 ft. away from the rolling mill, right, at Third Mill. A forklift manipulator, far right, carries depleted uranium plates to the scale. Before the new scale was installed, the forklift had to travel about 150 ft. to reach the scale.

A new scale, left, is now about 10 ft. away from the rolling mill, right, at Third Mill. A forklift manipulator, far right, carries depleted uranium plates to the scale. Before the new scale was installed, the forklift had to travel about 150 ft. to reach the scale.

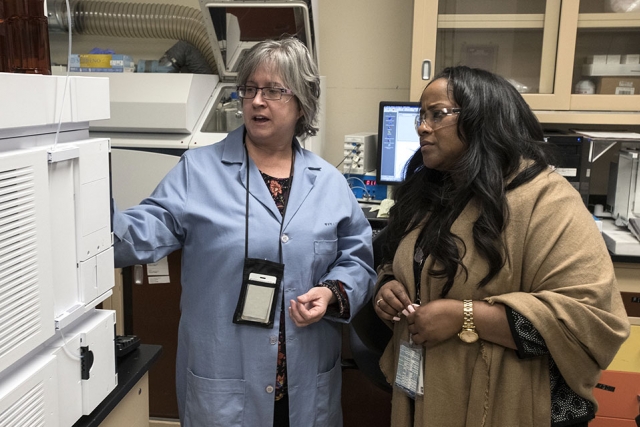

Courtney Edenfield contributes to the mission as a technician in Analytical Chemistry Mission Operations at Y-12.

Take 5 minutes and learn about Courtney Edenfield, an Analytical Chemistry technician at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Courtney Edenfield contributes to the mission as a technician in Analytical Chemistry Mission Operations at Y-12.

Take 5 minutes and learn about Courtney Edenfield, an Analytical Chemistry technician at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

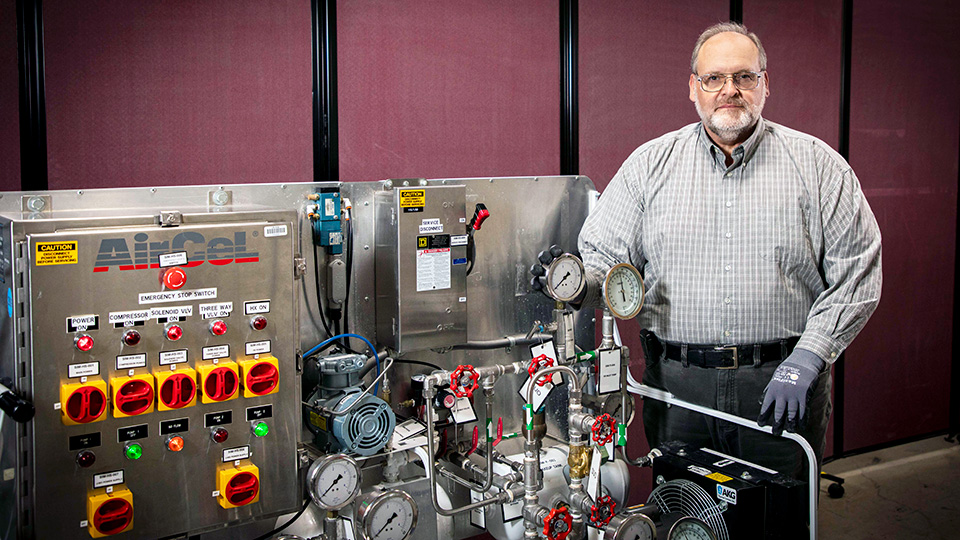

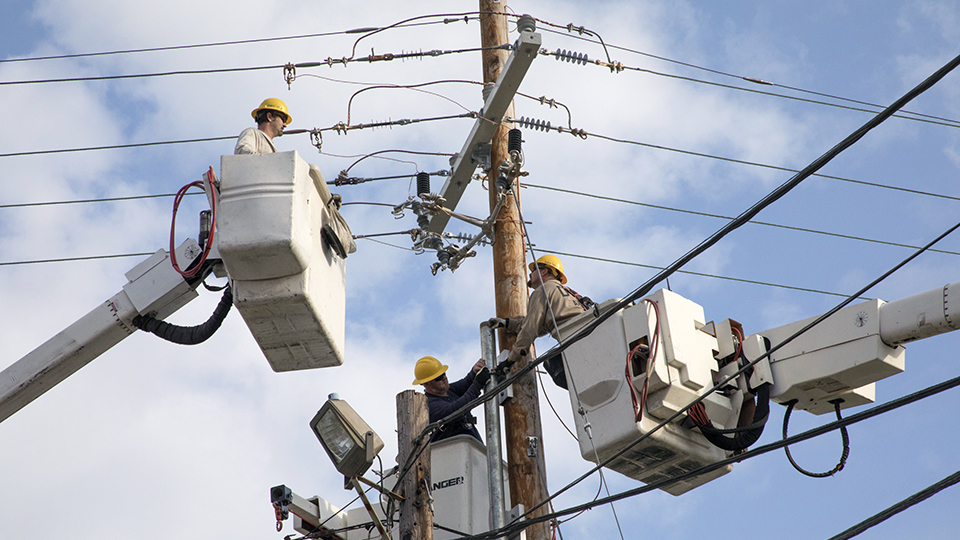

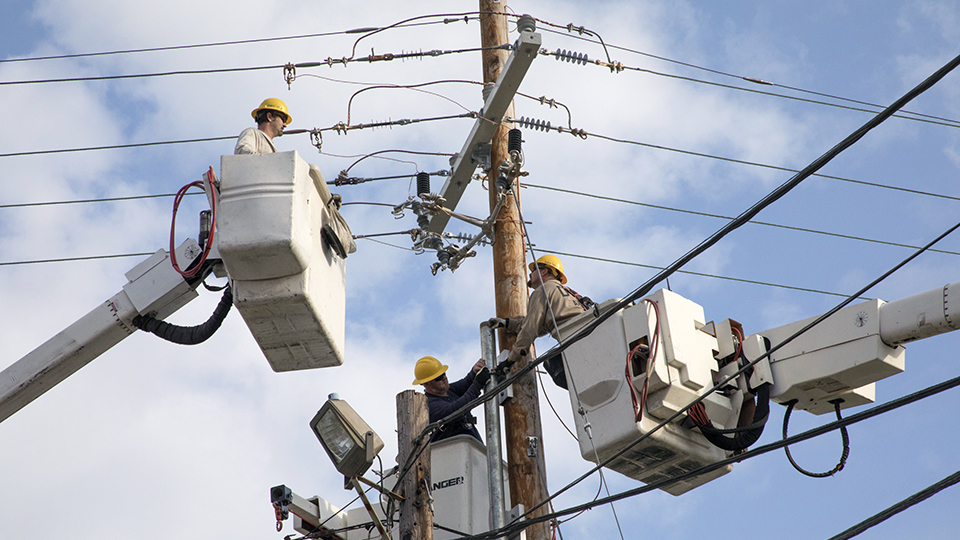

Utilities technicians are part of the Y-12 Infrastructure labor force, with the majority performing hands on work.

It is safe to say that working 1 million hours without a recordable injury is a big deal, especially when an organization’s work is physical and happens “in the elements.”

Utilities technicians are part of the Y-12 Infrastructure labor force, with the majority performing hands on work.

It is safe to say that working 1 million hours without a recordable injury is a big deal, especially when an organization’s work is physical and happens “in the elements.”

Y-12’s Alicia Swift has been named to the 2023 University of Tennessee Volunteer 40 under 40 Class.

Swift is director of Nonproliferation and Arms Control at Consolidated Nuclear Security. She joins an elite class of young professionals who have excelled since completing their degrees at UT Knoxville.

Y-12’s Alicia Swift has been named to the 2023 University of Tennessee Volunteer 40 under 40 Class.

Swift is director of Nonproliferation and Arms Control at Consolidated Nuclear Security. She joins an elite class of young professionals who have excelled since completing their degrees at UT Knoxville.

A poster produced in the 1990s paid tribute to the Seawolf submarine.

The removal of a big machine at Y-12’s Alpha-1 facility is a big deal.

A poster produced in the 1990s paid tribute to the Seawolf submarine.

The removal of a big machine at Y-12’s Alpha-1 facility is a big deal.

Cultivating contracts with small businesses is a component of Consolidated Nuclear Security’s overall mission at Pantex and Y-12, a goal passed down from the Small Business Administration through the U.S. Department of Energy.

Cultivating contracts with small businesses is a component of Consolidated Nuclear Security’s overall mission at Pantex and Y-12, a goal passed down from the Small Business Administration through the U.S. Department of Energy.

Alyssa Gibson is a current Veteran to Engineer intern working in both Waste Management and Piping/Processing Facility Design while earning her bachelor’s degree in mechanical engineering.

“What am I going to do when I grow up?”

Alyssa Gibson is a current Veteran to Engineer intern working in both Waste Management and Piping/Processing Facility Design while earning her bachelor’s degree in mechanical engineering.

“What am I going to do when I grow up?”

Consolidated Nuclear Security President and Chief Executive Officer Rich Tighe.

Consolidated Nuclear Security President and Chief Executive Officer Rich Tighe.

Y-12’s Thomas Duncan (left) and Donnie Walker are members of the Special Government Employee program.

Y-12’s Thomas Duncan (left) and Donnie Walker are members of the Special Government Employee program.

Meet George Haynes, deputy chief information security officer at Y-12, who plays a key role in the security and strategic defense of our network and systems.

All views and opinions are the employee’s and do not necessarily reflect those of CNS.

Meet George Haynes, deputy chief information security officer at Y-12, who plays a key role in the security and strategic defense of our network and systems.

All views and opinions are the employee’s and do not necessarily reflect those of CNS.

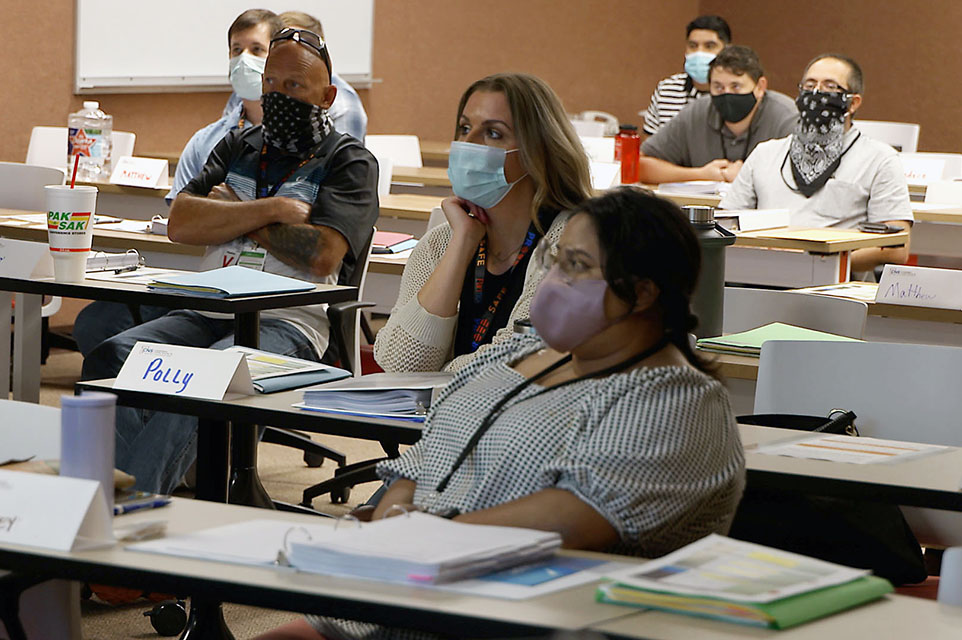

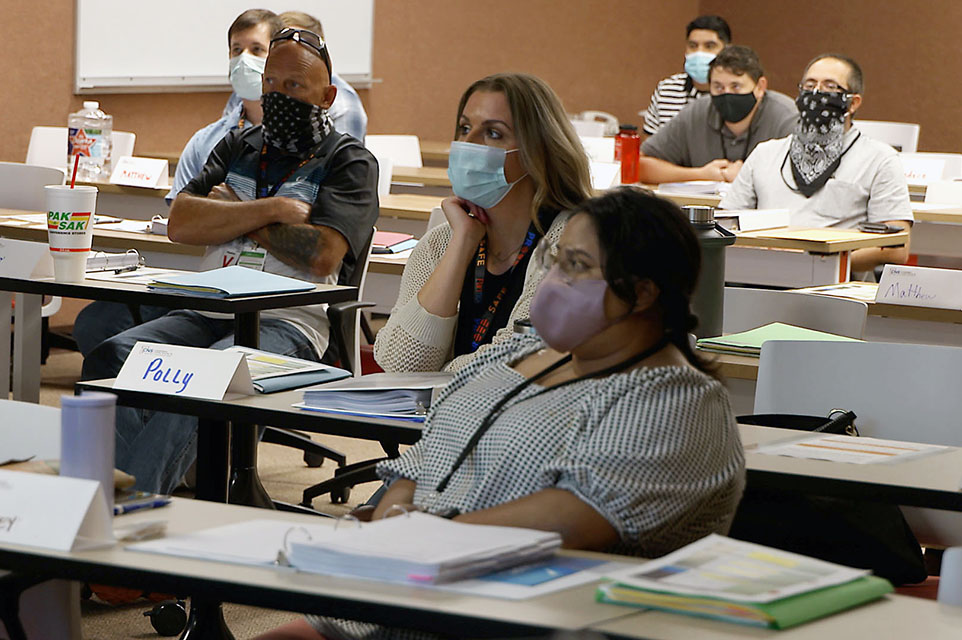

A recent 34-member Tactical Response Force 100 class included 25 trainees from Los Alamos National Laboratory in New Mexico.

A recent 34-member Tactical Response Force 100 class included 25 trainees from Los Alamos National Laboratory in New Mexico.

What are you willing to deal with to get the job done?

For members of the Y-12 International HEU Remove Program technical team, removing highly enriched uranium from sites in Japan during the pandemic required a lot of planning, adapting, and — especially — patience.

What are you willing to deal with to get the job done?

For members of the Y-12 International HEU Remove Program technical team, removing highly enriched uranium from sites in Japan during the pandemic required a lot of planning, adapting, and — especially — patience.

Take 5 minutes and learn about Max Robertson, director of Information Technology Business Operations at Pantex and Y-12. All views and opinions are the employee’s and do not necessarily reflect those of CNS.

Take 5 minutes and learn about Max Robertson, director of Information Technology Business Operations at Pantex and Y-12. All views and opinions are the employee’s and do not necessarily reflect those of CNS.

Congratulations to the recipients of the 2021 National Nuclear Security Administration’s security awards. The results were recently announced by NNSA's Associate Administrator and Chief of Defense Nuclear Security Jeff Johnson, and three of the four awards went to either Consolidated Nuclear Security or NNSA Production Office employees. A ceremony was recently held for those receiving the honors.

Congratulations to the recipients of the 2021 National Nuclear Security Administration’s security awards. The results were recently announced by NNSA's Associate Administrator and Chief of Defense Nuclear Security Jeff Johnson, and three of the four awards went to either Consolidated Nuclear Security or NNSA Production Office employees. A ceremony was recently held for those receiving the honors.

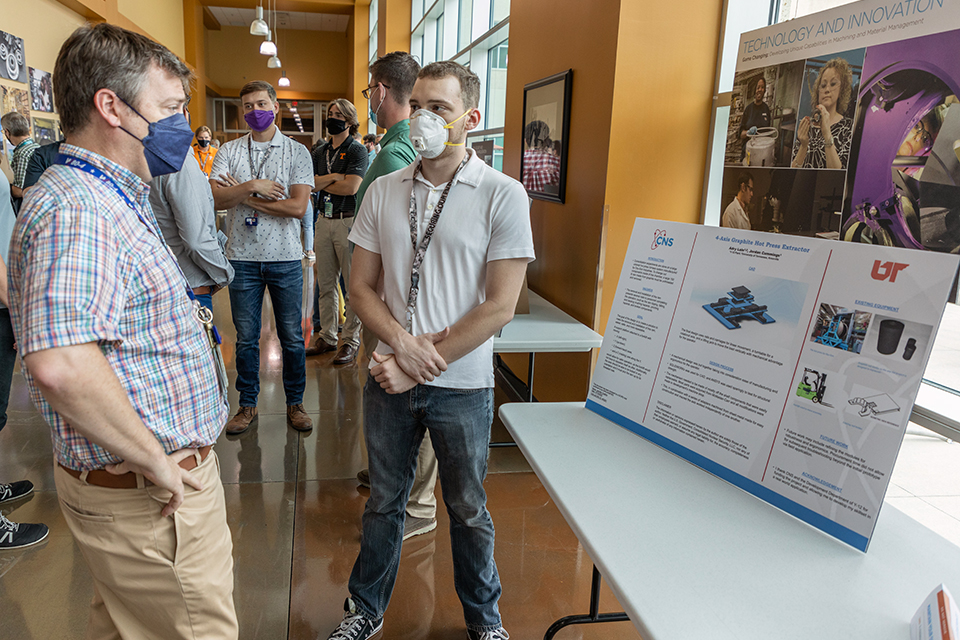

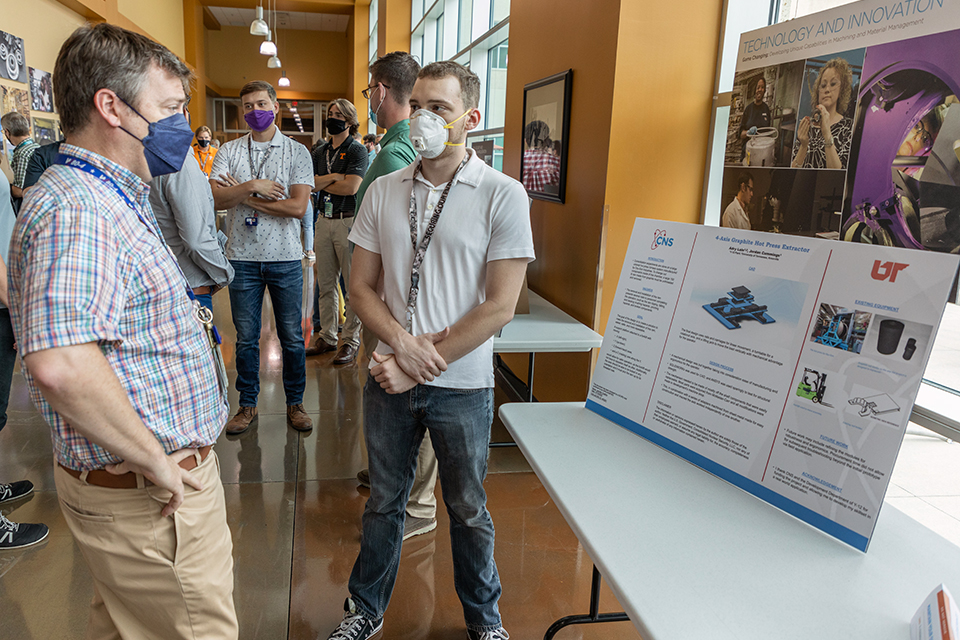

Adry Lain (center), an intern who worked with Y-12 Development, explains his project at the 2022 Intern Expo.

Adry Lain (center), an intern who worked with Y-12 Development, explains his project at the 2022 Intern Expo.

Lloyd Jollay addresses participants at the Nuclear Opportunities Workshop, presented by the East Tennessee Economic Council.

Lloyd Jollay addresses participants at the Nuclear Opportunities Workshop, presented by the East Tennessee Economic Council.

Y-12 Engineer Katie Romba, posing with one of her paintings

Engineering is defined as the “creative application of scientific principles to design or develop structures, machines, apparatus, or manufacturing processes.”

The term engineering is derived from the Latin ingenium, meaning “cleverness” and ingeniare, meaning to “contrive or devise.”

Y-12 Engineer Katie Romba, posing with one of her paintings

Engineering is defined as the “creative application of scientific principles to design or develop structures, machines, apparatus, or manufacturing processes.”

The term engineering is derived from the Latin ingenium, meaning “cleverness” and ingeniare, meaning to “contrive or devise.”

One of two new cranes that will assist in the rolling and forming processes for depleted uranium.

One of two new cranes that will assist in the rolling and forming processes for depleted uranium.

One of the New Employee Orientation classes during 2022 at Y-12’s New Hope Center.

One of the New Employee Orientation classes during 2022 at Y-12’s New Hope Center.

At the Global Security Analysis and Training Learning Lab, the use of different virtual or augmented headsets allow people to communicate with others across great distances for common objectives.

At the Global Security Analysis and Training Learning Lab, the use of different virtual or augmented headsets allow people to communicate with others across great distances for common objectives.

Personnel are shown in the NOC/SOC Control Room, surrounded by monitors used to assess the quality and security of the CNS network.

Personnel are shown in the NOC/SOC Control Room, surrounded by monitors used to assess the quality and security of the CNS network.

Y-12 employees recently gathered to celebrate the conclusion of the roadmap.

Nuclear Criticality Safety is a foundation for much of the work performed at Y-12, and site leadership recognized the importance of improving the program to continue to ensure the safety of enriched uranium operations.

Y-12 employees recently gathered to celebrate the conclusion of the roadmap.

Nuclear Criticality Safety is a foundation for much of the work performed at Y-12, and site leadership recognized the importance of improving the program to continue to ensure the safety of enriched uranium operations.

This team helps improve how weapons parts are machined.

In racing, a pit crew works fast to get a car back on the track. At Y-12, a group called the PIT Crew has helped speed up production of a weapon part and lowered costs.

The crew consists of machinists who are developing process improvements that reduce time to manufacture components.

This team helps improve how weapons parts are machined.

In racing, a pit crew works fast to get a car back on the track. At Y-12, a group called the PIT Crew has helped speed up production of a weapon part and lowered costs.

The crew consists of machinists who are developing process improvements that reduce time to manufacture components.

Senior Director of Communications Jason Bohne explains facets of the Y-12 mission during a site tour for new summer interns.

Senior Director of Communications Jason Bohne explains facets of the Y-12 mission during a site tour for new summer interns.

Mike Ellis (right), a 20-year Y-12 employee, is the new program manager for Y-12’s Plant Directed Research and Development program and is acting in the same role at Pantex. Ellis and Elijah Barlow (left) discuss a process being investigated for use with Y-12’s lithium stream.

Mike Ellis (right), a 20-year Y-12 employee, is the new program manager for Y-12’s Plant Directed Research and Development program and is acting in the same role at Pantex. Ellis and Elijah Barlow (left) discuss a process being investigated for use with Y-12’s lithium stream.

Y-12 employees participate in hands on training at the new salvage yard as part of Sustainability and Stewardship’s expanded program.

Y-12 employees participate in hands on training at the new salvage yard as part of Sustainability and Stewardship’s expanded program.

The Y-12 Fire Department sent a tanker to help contain the recent wildfires in Sevier County. The tanker supplied water to other fire departments who participated in the firefighting effort.

The Y-12 Fire Department sent a tanker to help contain the recent wildfires in Sevier County. The tanker supplied water to other fire departments who participated in the firefighting effort.

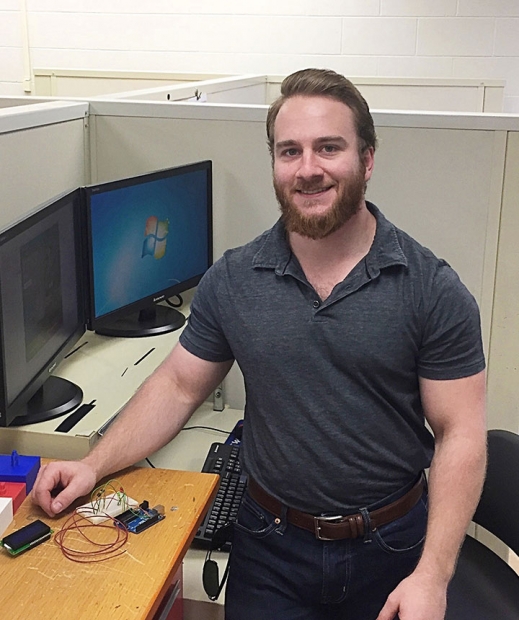

Pantex Development Engineer Paul Aguirre of the Tracking and Sensor Networks Integrated Project Team with some of the project equipment.

Pantex Development Engineer Paul Aguirre of the Tracking and Sensor Networks Integrated Project Team with some of the project equipment.

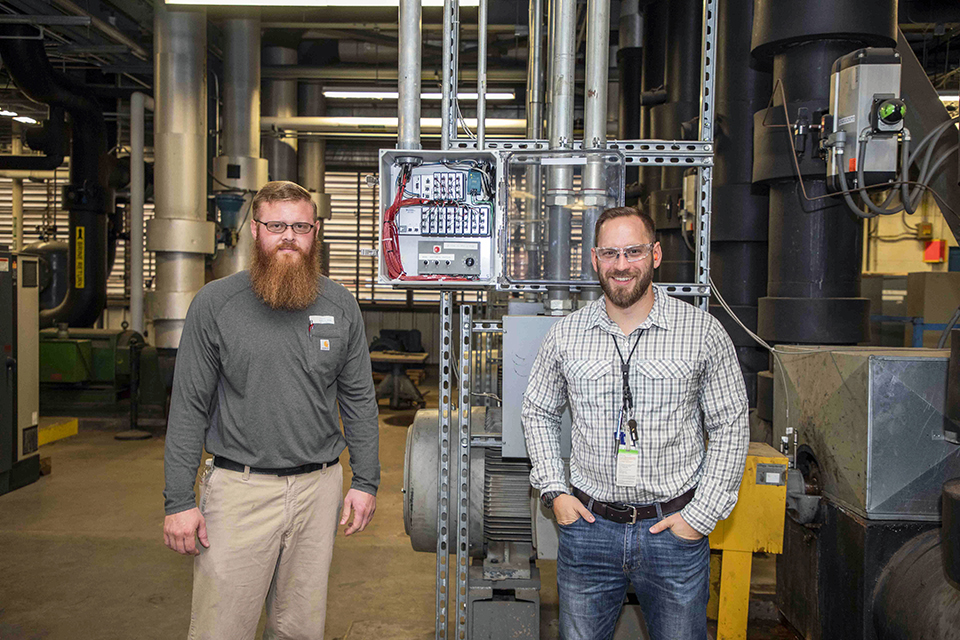

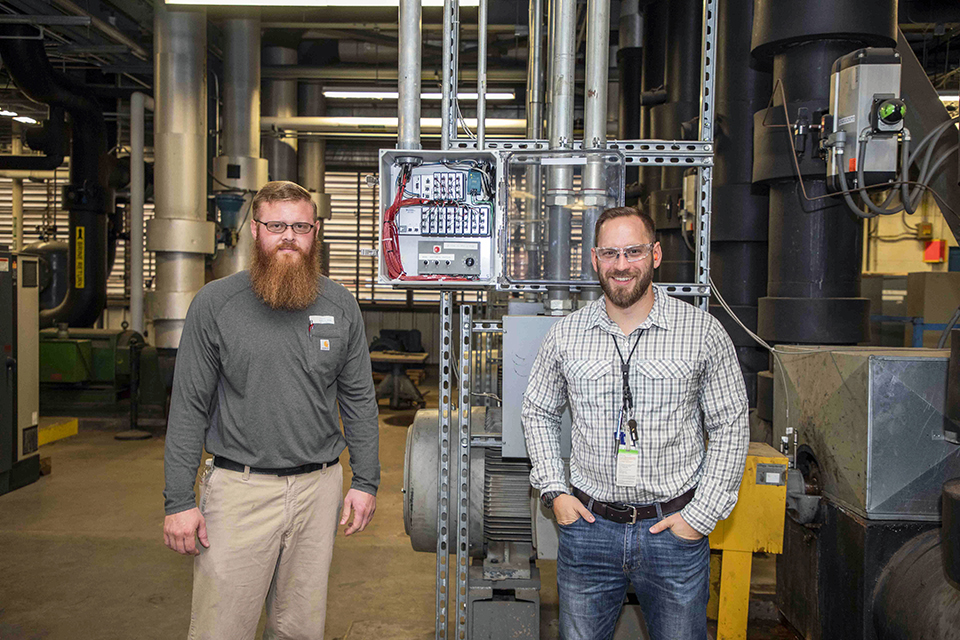

Ronald Bolden Jr. (left) and Luke Birt, pause for a photo with Building 9767-13’s installation

Ronald Bolden Jr. (left) and Luke Birt, pause for a photo with Building 9767-13’s installation

PrYde Program Manager Margaret Woods shows off a Best Facility sign that recognizes Best Practices, one of two new inspection awards given quarterly.

Take 5 minutes and learn about Margaret Woods, manager of the PrYde Program at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

PrYde Program Manager Margaret Woods shows off a Best Facility sign that recognizes Best Practices, one of two new inspection awards given quarterly.

Take 5 minutes and learn about Margaret Woods, manager of the PrYde Program at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Five million hours. That’s a difficult-to-conceive amount of time. To put it in perspective, you would have to drive back and forth between Amarillo, Texas, and Oak Ridge, Tennessee more than 150,000 times to hit five million hours. Better pack some snacks for the road!

Five million hours. That’s a difficult-to-conceive amount of time. To put it in perspective, you would have to drive back and forth between Amarillo, Texas, and Oak Ridge, Tennessee more than 150,000 times to hit five million hours. Better pack some snacks for the road!

Pantex and Y-12 Occupational Health Services received top scores in all applicable categories in a recent Survey Report conducted by the Accreditation Association for Ambulatory Health Care (AAAHC) and, as a result, both sites were awarded a full three year accreditation. The healthcare accrediting body performs inspections of more than 6,000 healthcare facilities around the country.

Pantex and Y-12 Occupational Health Services received top scores in all applicable categories in a recent Survey Report conducted by the Accreditation Association for Ambulatory Health Care (AAAHC) and, as a result, both sites were awarded a full three year accreditation. The healthcare accrediting body performs inspections of more than 6,000 healthcare facilities around the country.

This construction site (photo from April 2022) will one day house the Y-12 Fire Department, replacing a facility that was built in the 1940s.

This construction site (photo from April 2022) will one day house the Y-12 Fire Department, replacing a facility that was built in the 1940s.

Workers watch an incident reenactment at Y-12 Construction as part of a recent Hand Injury Prevention Campaign.

While many tools can be carried in a construction worker’s tool belt, none are more important than the ones that fasten it.

Workers watch an incident reenactment at Y-12 Construction as part of a recent Hand Injury Prevention Campaign.

While many tools can be carried in a construction worker’s tool belt, none are more important than the ones that fasten it.

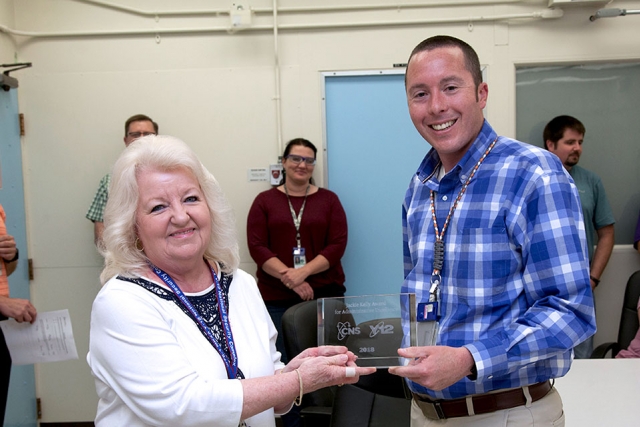

Administrative professional Renea Dosher won the Pantex Jackie Kelly Award for 2022. With her is Deputy Chief Information Officer Rick Day, who co-nominated her with Chief Information Officer Joe Harris.

Administrative professional Renea Dosher won the Pantex Jackie Kelly Award for 2022. With her is Deputy Chief Information Officer Rick Day, who co-nominated her with Chief Information Officer Joe Harris.

Y‑12 employee Michael Laws stands in front of the house from which he pulled two children during a recent fire.

It has been proven time and again that Y‑12 employees are not only an asset to CNS, but also to the communities in which they live. Recently one employee showed great bravery by saving two children during a life‑threatening situation.

Y‑12 employee Michael Laws stands in front of the house from which he pulled two children during a recent fire.

It has been proven time and again that Y‑12 employees are not only an asset to CNS, but also to the communities in which they live. Recently one employee showed great bravery by saving two children during a life‑threatening situation.

A special touch: Holding to the masons’ tradition, a 1943 coin, the year Building 9731 was built, was placed into the pavement.

A special touch: Holding to the masons’ tradition, a 1943 coin, the year Building 9731 was built, was placed into the pavement.

Zuleyma Carruba-Rogel engages a class of new employees at Pantex.

Zuleyma Carruba-Rogel engages a class of new employees at Pantex.

Zuleyma Carruba-Rogel engages a class of new employees at Pantex.

Zuleyma Carruba-Rogel engages a class of new employees at Pantex.

Wayne Carlton helps guide Y-12 to become a more recycling friendly workplace. Those efforts have earned him a Lifetime Achievement Award from the Department of Energy.

Take a few minutes and learn about Wayne Carlton, an environmental engineer at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of Consolidated Nuclear Security.

Wayne Carlton helps guide Y-12 to become a more recycling friendly workplace. Those efforts have earned him a Lifetime Achievement Award from the Department of Energy.

Take a few minutes and learn about Wayne Carlton, an environmental engineer at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of Consolidated Nuclear Security.

Wayne Carlton helps guide Y-12 to become a more recycling friendly workplace. Those efforts have earned him a Lifetime Achievement Award from the Department of Energy.

Take a few minutes and learn about Wayne Carlton, an environmental engineer at Y-12. All views and opinions are the employee’s own and do not necessarily reflect those of Consolidated Nuclear Security.

From left: Caitlin Hoch Nussbaum and Tori Smith are two of the University of Tennessee College of Law students who have been interning at Y-12.

From left: Caitlin Hoch Nussbaum and Tori Smith are two of the University of Tennessee College of Law students who have been interning at Y-12.

Career Opportunities for New Engineers, also known as Career ONE, is an engineering rotation and development program for Pantex and Y-12 engineers who have recently graduated.

Career Opportunities for New Engineers, also known as Career ONE, is an engineering rotation and development program for Pantex and Y-12 engineers who have recently graduated.

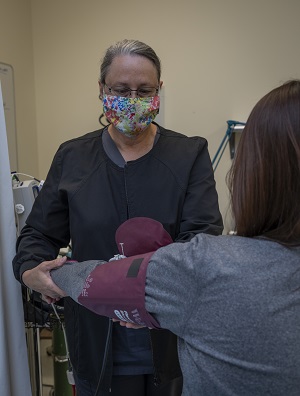

Shoulders are common problem spots for physical therapy patients. Y-12 physical therapist Gary Hall examines the arm of a client.

Shoulders are common problem spots for physical therapy patients. Y-12 physical therapist Gary Hall examines the arm of a client.

Pantexan Edward Graef and Y-12er Matthew Willard (not pictured) are part of the Sandia Weapon Intern Program, Class of 2022.

Two CNS employees are joining the ranks of the prestigious Sandia Weapon Intern Program (WIP) for the class of 2022. Edward Graef, Pantex physics senior specialist, and Matthew Willard, Y-12 process engineer, began the program in 2021.

Pantexan Edward Graef and Y-12er Matthew Willard (not pictured) are part of the Sandia Weapon Intern Program, Class of 2022.

Two CNS employees are joining the ranks of the prestigious Sandia Weapon Intern Program (WIP) for the class of 2022. Edward Graef, Pantex physics senior specialist, and Matthew Willard, Y-12 process engineer, began the program in 2021.

During a September Pantex onboarding session, new employees learn about the opportunities offered at Pantex and Y-12 and how all employees play a vital role in meeting the mission.

During a September Pantex onboarding session, new employees learn about the opportunities offered at Pantex and Y-12 and how all employees play a vital role in meeting the mission.

Kami Bush, IT Systems administrator, stands among servers in Y-12’s data center.

Kami Bush, IT Systems administrator, stands among servers in Y-12’s data center.

Advanced Lithium Cell Project Team standing next to the prototype after it was successfully operated.

Advanced Lithium Cell Project Team standing next to the prototype after it was successfully operated.

Y‑12 engineers Brad Langley (right) and Josh Metcalf worked on a continuous‑improvement enterprise to standardize glovebox equipment.

In the classic Wendy’s commercial, a fast‑food worker uttered the iconic line, “Parts is parts,” meaning any part of the chicken is just as good as the other, when it comes to making a chicken patty.

Y‑12 engineers Brad Langley (right) and Josh Metcalf worked on a continuous‑improvement enterprise to standardize glovebox equipment.

In the classic Wendy’s commercial, a fast‑food worker uttered the iconic line, “Parts is parts,” meaning any part of the chicken is just as good as the other, when it comes to making a chicken patty.

Take a few minutes and learn about CNS’s Mike Mulligan, Subcontract Management Program lead. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

A stint as a barista brewed changes in Mike Mulligan’s life, professionally and personally.

Take a few minutes and learn about CNS’s Mike Mulligan, Subcontract Management Program lead. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

A stint as a barista brewed changes in Mike Mulligan’s life, professionally and personally.

Take a few minutes and learn about David Zakrzwski, CNS’s Information Solutions and Services deputy chief information officer at Y-12. All views and opinions are the employee’s and do not necessarily reflect those of CNS.

Take a few minutes and learn about David Zakrzwski, CNS’s Information Solutions and Services deputy chief information officer at Y-12. All views and opinions are the employee’s and do not necessarily reflect those of CNS.

Rack framed and wrapped for shipment at supplier’s facility

Racks, or “multi-commodity pipe rack modules,” are one of the many components that go into building the Uranium Processing Facility. Achieving 100% rack delivery required tremendous effort and planning, but the team completed the feat ahead of schedule.

Rack framed and wrapped for shipment at supplier’s facility

Racks, or “multi-commodity pipe rack modules,” are one of the many components that go into building the Uranium Processing Facility. Achieving 100% rack delivery required tremendous effort and planning, but the team completed the feat ahead of schedule.

All community colleges are expected to educate and train students to prepare them for a future career, but Roane State Community College goes a step further. At its Harriman campus, Roane State established the Raider Pantry, a facility that provides supplies for students dealing with the issue of food insecurity.

All community colleges are expected to educate and train students to prepare them for a future career, but Roane State Community College goes a step further. At its Harriman campus, Roane State established the Raider Pantry, a facility that provides supplies for students dealing with the issue of food insecurity.

The east side of the Uranium Processing Facility's Main Process Building

The east side of the Uranium Processing Facility's Main Process Building

This LiveWise mural brands the renovated fitness centers and makes the centers easily recognizable.

Some rejuvenating reps have the East and West LIFE Centers at Y-12 looking pretty buff.

The 11-year old structures have received makeovers. They now boast fresh paint, power washed and replaced trim, and new eye catching murals. Inside the West site, bathrooms sport new flooring, and ceiling tiles have been replaced.

This LiveWise mural brands the renovated fitness centers and makes the centers easily recognizable.

Some rejuvenating reps have the East and West LIFE Centers at Y-12 looking pretty buff.

The 11-year old structures have received makeovers. They now boast fresh paint, power washed and replaced trim, and new eye catching murals. Inside the West site, bathrooms sport new flooring, and ceiling tiles have been replaced.

Thanks to the CNS General Workplace Improvement Program, the Pantex and Y-12 sites have received several upgrades.

Thanks to the CNS General Workplace Improvement Program, the Pantex and Y-12 sites have received several upgrades.

In this photo from 2019, a group of Program Management University graduates gather to celebrate the end of their sessions. Now, most of the classes are virtual with in person sessions once travel restrictions are relaxed.

In this photo from 2019, a group of Program Management University graduates gather to celebrate the end of their sessions. Now, most of the classes are virtual with in person sessions once travel restrictions are relaxed.

Congratulations to the Bechtel Global Scholars with ties to Pantex, Y 12, and the Uranium Processing Facility.

The 2021 Bechtel Global Scholars program awarded a total of $75,000 in college funds to 25 students in six countries. The $3,000 scholarship goes to students in their first year of studies at an accredited college, university, vocational institute, or technical school.

Congratulations to the Bechtel Global Scholars with ties to Pantex, Y 12, and the Uranium Processing Facility.

The 2021 Bechtel Global Scholars program awarded a total of $75,000 in college funds to 25 students in six countries. The $3,000 scholarship goes to students in their first year of studies at an accredited college, university, vocational institute, or technical school.

A chemist performs an initial sample analysis.

A chemist performs an initial sample analysis.

Jan West (left) and Jeff Barnard (right) stand in front of the new flag at Post 5.

Jan West (left) and Jeff Barnard (right) stand in front of the new flag at Post 5.

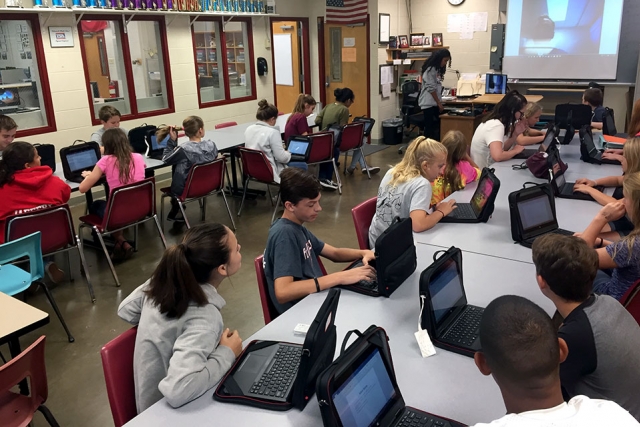

Students from as far away as New York participated in the cybersecurity camp sponsored by Y-12 National Security Complex.

Students from as far away as New York participated in the cybersecurity camp sponsored by Y-12 National Security Complex.

In a time of heartache and abuse, organizations like the Knoxville Family Justice Center are there for victims of domestic violence

In a time of heartache and abuse, organizations like the Knoxville Family Justice Center are there for victims of domestic violence

Kami Bush, who supports CNS’s VMware virtual infrastructure, stands in front of a Y‑12 server rack in Building 9117.

Kami Bush, who supports CNS’s VMware virtual infrastructure, stands in front of a Y‑12 server rack in Building 9117.

A political science major at UT, Asya H. is gaining knowledge about nuclear safeguards during her internship.

Asya H. comes from a family of engineers.

A political science major at UT, Asya H. is gaining knowledge about nuclear safeguards during her internship.

Asya H. comes from a family of engineers.

The Boys & Girls Clubs of the Tennessee Valley is one of many organizations that helps provide childcare services to families. By the Boys & Girls Clubs keeping its doors open during the pandemic, children were able to continue being children.

The Boys & Girls Clubs of the Tennessee Valley is one of many organizations that helps provide childcare services to families. By the Boys & Girls Clubs keeping its doors open during the pandemic, children were able to continue being children.

The Boys & Girls Clubs of the Tennessee Valley is one of many organizations that helps provide childcare services to families. By the Boys & Girls Clubs keeping its doors open during the pandemic, children were able to continue being children.

The Boys & Girls Clubs of the Tennessee Valley is one of many organizations that helps provide childcare services to families. By the Boys & Girls Clubs keeping its doors open during the pandemic, children were able to continue being children.

Michael Dunn Center was one of several East Tennessee organizations CNS and the ETF Neighbor to Neighbor fund helped during the COVID-19 pandemic.

Michael Dunn Center was one of several East Tennessee organizations CNS and the ETF Neighbor to Neighbor fund helped during the COVID-19 pandemic.

Michael Dunn Center was one of several East Tennessee organizations CNS and the ETF Neighbor to Neighbor fund helped during the COVID-19 pandemic.

Shipping crates of the Main Casting Glovebox Line, Group 1 in MPB East

Shipping crates of the Main Casting Glovebox Line, Group 1 in MPB East

Shipping crates of the Main Casting Glovebox Line, Group 1 in MPB East

UPF Electrician inspects wiring in the 13.8kV switchgear (Per work assessment and STAART card requirements gloves are not required during the activities pictured)

UPF Electrician inspects wiring in the 13.8kV switchgear (Per work assessment and STAART card requirements gloves are not required during the activities pictured)

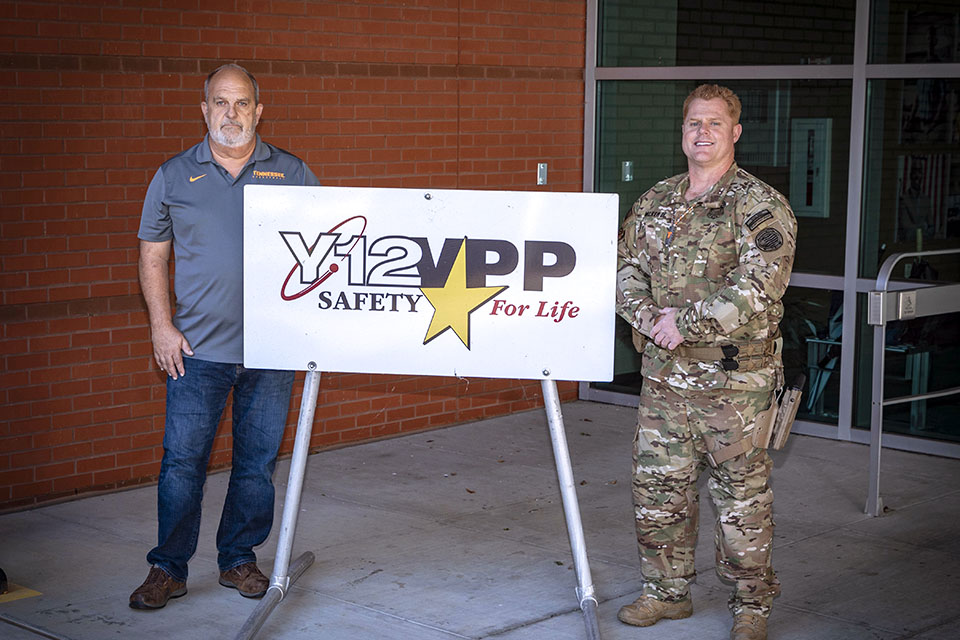

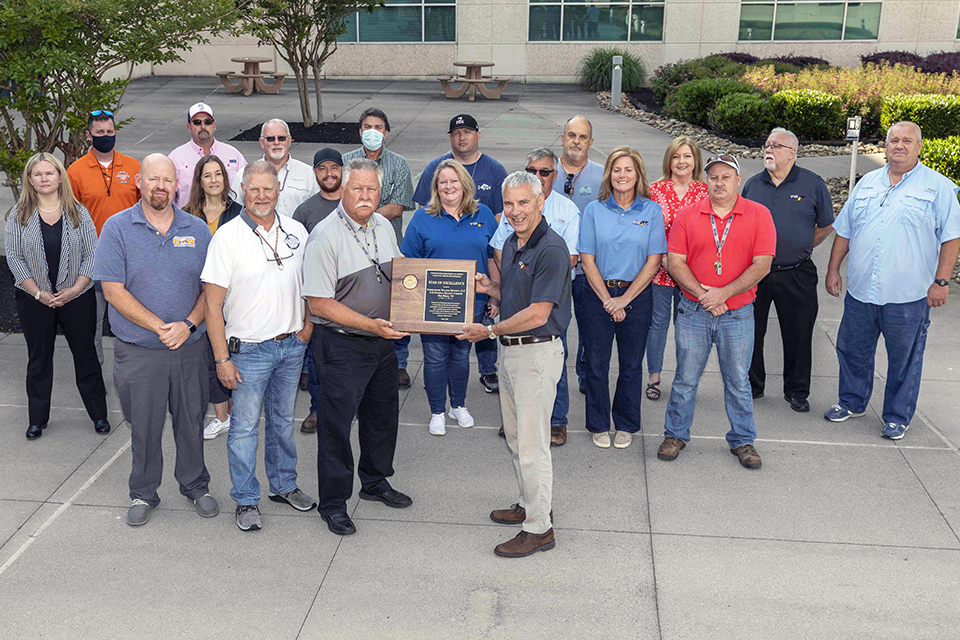

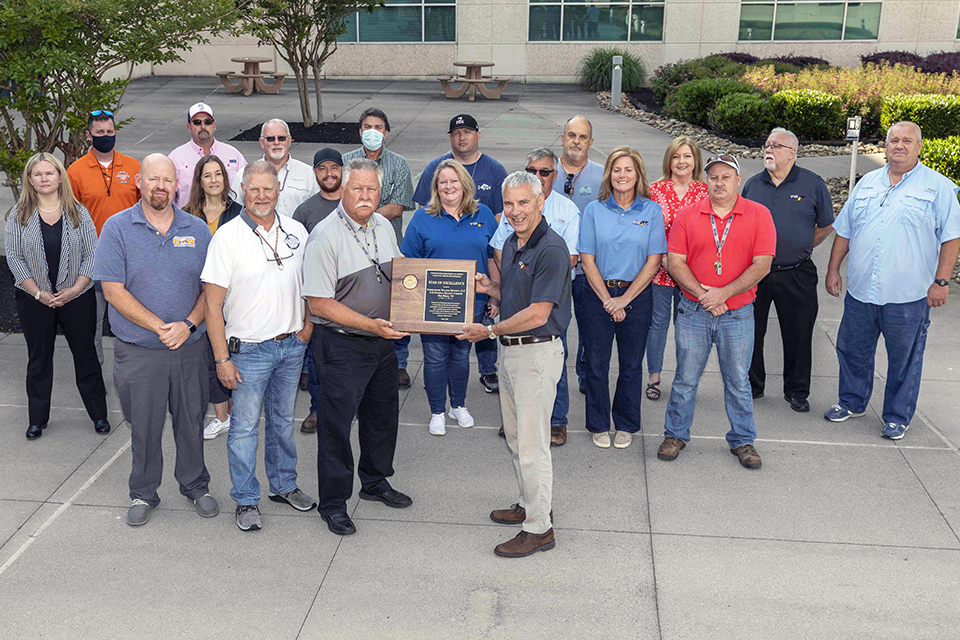

Accepting the Star of Excellence award plaque from Gene Sievers, Y-12 Site Manager, is Mike Thompson (left), president of the Atomic Trades and Labor Council, with members of the safety team and their representatives in attendance.

Accepting the Star of Excellence award plaque from Gene Sievers, Y-12 Site Manager, is Mike Thompson (left), president of the Atomic Trades and Labor Council, with members of the safety team and their representatives in attendance.

Thanks to teamwork, a plan to restore power during a scheduled outage kept the mission on schedule.

Thanks to teamwork, a plan to restore power during a scheduled outage kept the mission on schedule.

Welder Joel Chavez welds a tooling fixture.

Y-12’s can do attitude is legendary. Perhaps the men and women of General Manufacturing Operations best exemplify that mindset.

“If it can’t be done anywhere else, bring it to us. We can do it,” said Wendell Laughter, a production specialist with 16 years of experience in Building 9201 1, known as Alpha 1. “We’re a one stop shop.”

Welder Joel Chavez welds a tooling fixture.

Y-12’s can do attitude is legendary. Perhaps the men and women of General Manufacturing Operations best exemplify that mindset.

“If it can’t be done anywhere else, bring it to us. We can do it,” said Wendell Laughter, a production specialist with 16 years of experience in Building 9201 1, known as Alpha 1. “We’re a one stop shop.”

Emory Valley Center staff members are appreciative of the grant from CNS that was used to purchase personal protective equipment for employees.

Emory Valley Center staff members are appreciative of the grant from CNS that was used to purchase personal protective equipment for employees.

Emory Valley Center staff members are appreciative of the grant from CNS that was used to purchase personal protective equipment for employees.

It’s not uncommon at the Y-12 National Security Complex to find that multiple generations from the same family have worked on site. At the Uranium Processing Facility (UPF) Project, two father-son duos don’t have to go far to celebrate Father’s Day, as they work side-by-side building UPF.

It’s not uncommon at the Y-12 National Security Complex to find that multiple generations from the same family have worked on site. At the Uranium Processing Facility (UPF) Project, two father-son duos don’t have to go far to celebrate Father’s Day, as they work side-by-side building UPF.

As the world grappled with the economic impacts of the COVID-19 pandemic, CNS continued looking for ways to help our communities. The company turned to the East Tennessee Foundation and its Neighbor to Neighbor Fund.

As the world grappled with the economic impacts of the COVID-19 pandemic, CNS continued looking for ways to help our communities. The company turned to the East Tennessee Foundation and its Neighbor to Neighbor Fund.

Crews demolished Pantex Buildings 12-106 and 12-106A in FY 2020 as part of the disposition plan enabled by the opening of the John C. Drummond Center. EFDP characterized the facilities, removed waste, demolished the structures, and disposed of all demolition debris.

Crews demolished Pantex Buildings 12-106 and 12-106A in FY 2020 as part of the disposition plan enabled by the opening of the John C. Drummond Center. EFDP characterized the facilities, removed waste, demolished the structures, and disposed of all demolition debris.

Y-12 Fire Department recently tested a new environmentally safer foam with the Alcoa Fire Department.

Y-12 Fire Department recently tested a new environmentally safer foam with the Alcoa Fire Department.

Installation of the 13.8kV switchgear in the Uranium Processing Facility’s Mechanical Electrical Building

The Uranium Processing Facility (UPF) Project ‘flipped the switch’ as it energized the first of the facility’s electrical power systems.

Installation of the 13.8kV switchgear in the Uranium Processing Facility’s Mechanical Electrical Building

The Uranium Processing Facility (UPF) Project ‘flipped the switch’ as it energized the first of the facility’s electrical power systems.

The Process Support Facilities at the Uranium Processing Facility

The Process Support Facilities at the Uranium Processing Facility

Members of the Region 2 Radiological Assistance Program preparing to mobilize at Super Bowl 55 in Tampa. From left, front row: Bill Riley, Steve Johnson, Jeff Barroso, and back row, Steve Cleveland, Jeff Bruner, Perry Pruitt, and Michael Murray. Team member Dale Perkins is not pictured.

Members of the Region 2 Radiological Assistance Program preparing to mobilize at Super Bowl 55 in Tampa. From left, front row: Bill Riley, Steve Johnson, Jeff Barroso, and back row, Steve Cleveland, Jeff Bruner, Perry Pruitt, and Michael Murray. Team member Dale Perkins is not pictured.

Meet Kadee Klimowicz, who worked at Y-12 while waiting on her training in the Space Operations field at Vandenberg Air Force Base to begin.

Meet Kadee Klimowicz, who worked at Y-12 while waiting on her training in the Space Operations field at Vandenberg Air Force Base to begin.

The shelter has perimeter benches that provide employees a place to sit. Rubber matting is also on the floor, providing a layer of cushion.

The shelter has perimeter benches that provide employees a place to sit. Rubber matting is also on the floor, providing a layer of cushion.

Dr. Warren Sayre, CNS corporate medical director and Y-12 site occupational medical director

The COVID‑19 pandemic has brought the science and profession of public health to the forefront of communities nationwide. Pantex and Y‑12 are fortunate to have physician medical directors, Dr. Warren Sayre and Dr. Michael Paston, who have extensive public health backgrounds.

Dr. Warren Sayre, CNS corporate medical director and Y-12 site occupational medical director

The COVID‑19 pandemic has brought the science and profession of public health to the forefront of communities nationwide. Pantex and Y‑12 are fortunate to have physician medical directors, Dr. Warren Sayre and Dr. Michael Paston, who have extensive public health backgrounds.

Michael Lovelady,

Y-12 Mission Engineering

See something? Take action. That’s what Michael Lovelady of Y-12 Mission Engineering did on a trip to work last fall.

Whatever you do, don’t call him a hero.

Michael Lovelady,

Y-12 Mission Engineering

See something? Take action. That’s what Michael Lovelady of Y-12 Mission Engineering did on a trip to work last fall.

Whatever you do, don’t call him a hero.

Paul Beckman,

Chief Information Security Officer

With peaked interest surrounding the coronavirus vaccine, cybercriminals are determined to exploit our feelings or anticipation in the form of social engineering. Reports have shown cyber threat actors baiting potential victims with vaccine-themed scams.

Paul Beckman,

Chief Information Security Officer

With peaked interest surrounding the coronavirus vaccine, cybercriminals are determined to exploit our feelings or anticipation in the form of social engineering. Reports have shown cyber threat actors baiting potential victims with vaccine-themed scams.

Learn something new about Bill Tindal, CNS’s chief operating officer.

Take 5 minutes and learn more about Bill Tindal, CNS’s chief operating officer.

Learn something new about Bill Tindal, CNS’s chief operating officer.

Take 5 minutes and learn more about Bill Tindal, CNS’s chief operating officer.

With technology essential to our daily lives, cybersecurity education is increasingly growing

With technology essential to our daily lives, cybersecurity education is increasingly growing

Executive director of Compassion Counseling Lakshmie Napagoda interacts with a client.

Executive director of Compassion Counseling Lakshmie Napagoda interacts with a client.

Demolition of Building 9720 22 at Y 12

More than ever before, the landscape of Pantex and Y-12 is changing. In FY 2020 alone, 46 infrastructure projects were completed, and an impressive 21 facilities (11 at Pantex and 10 at Y-12) were demolished.

Demolition of Building 9720 22 at Y 12

More than ever before, the landscape of Pantex and Y-12 is changing. In FY 2020 alone, 46 infrastructure projects were completed, and an impressive 21 facilities (11 at Pantex and 10 at Y-12) were demolished.

Heroes don’t always wear capes (but they do wear face coverings). These three Y-12ers jumped into action to help a Kentucky man suffering from dementia. (from left: Chris Griffis, Mark Butcher, and Jack Bolinger)

Most Y-12 employees try to be helpful. Last month, three Y-12ers proved that statement when they were in the right place at the right time.

Heroes don’t always wear capes (but they do wear face coverings). These three Y-12ers jumped into action to help a Kentucky man suffering from dementia. (from left: Chris Griffis, Mark Butcher, and Jack Bolinger)

Most Y-12 employees try to be helpful. Last month, three Y-12ers proved that statement when they were in the right place at the right time.

When it’s time to perform factory acceptance testing on a critical technology during a pandemic, what do you do? Since the product still must be delivered, you adapt by monitoring the work remotely.

Pre-pandemic, CNS and NPO staff would have sent several people on multiple trips to observe electrorefining testing. This time, because of COVID restrictions on the number of people allowed in the shop, the project team could only send two representatives.

When it’s time to perform factory acceptance testing on a critical technology during a pandemic, what do you do? Since the product still must be delivered, you adapt by monitoring the work remotely.

Pre-pandemic, CNS and NPO staff would have sent several people on multiple trips to observe electrorefining testing. This time, because of COVID restrictions on the number of people allowed in the shop, the project team could only send two representatives.

Development’s Trevor Roberts, Direct Material Manufacturing lead, isolates several key samples to be sent to Y-12’s Analytical Chemistry Organization.

Development’s Trevor Roberts, Direct Material Manufacturing lead, isolates several key samples to be sent to Y-12’s Analytical Chemistry Organization.

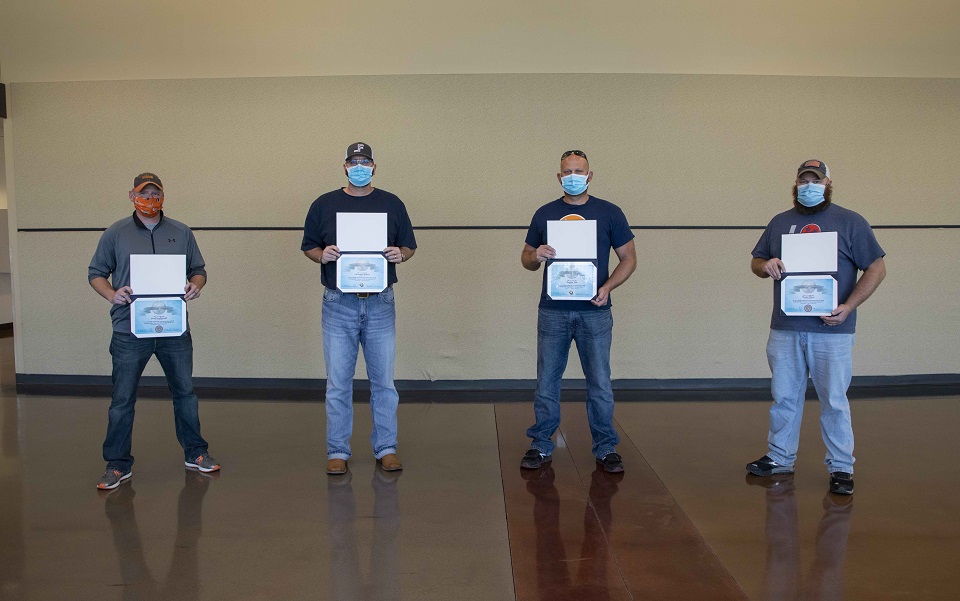

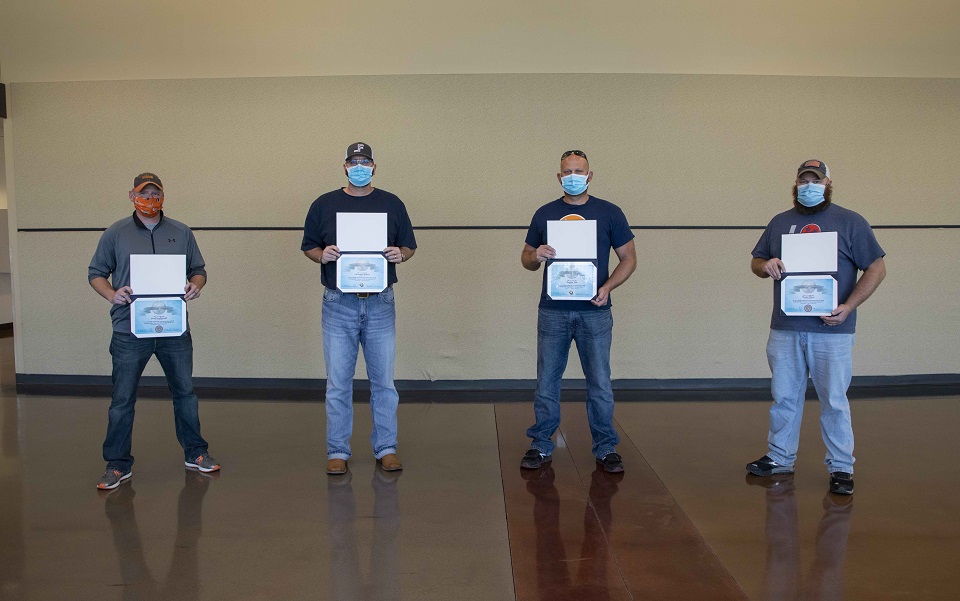

Y-12 Apprenticeship Program 2020 graduates present their diplomas. From left: Jacob Scarborough, electrician; Christopher Drinnon, pipefitter; Brandon Muir, pipefitter; and Dustin Wilson, electrician.

Y-12 Apprenticeship Program 2020 graduates present their diplomas. From left: Jacob Scarborough, electrician; Christopher Drinnon, pipefitter; Brandon Muir, pipefitter; and Dustin Wilson, electrician.

Consolidated Nuclear Security, LLC (CNS) is demonstrating a continued commitment to business partnership, even in the midst of the COVID-19 pandemic. As part of ongoing outreach to business owners and potential vendors, CNS representatives are continuing their Partners in Excellence (PIE) event series virtually.

Consolidated Nuclear Security, LLC (CNS) is demonstrating a continued commitment to business partnership, even in the midst of the COVID-19 pandemic. As part of ongoing outreach to business owners and potential vendors, CNS representatives are continuing their Partners in Excellence (PIE) event series virtually.

MEDIC’s newest bus was used for September’s mobile blood drive events at Y-12.

More Y-12 employees rolled up their sleeves in September to meet the growing need for blood donations in East Tennessee.

MEDIC’s newest bus was used for September’s mobile blood drive events at Y-12.

More Y-12 employees rolled up their sleeves in September to meet the growing need for blood donations in East Tennessee.

Congratulations to Kevin Shipp of Y-12 Engineering; he was awarded the 2020 Sandia National Laboratories Weapon Intern Program Leadership Award. He is a graduate of the 2020 program, which was the 25th class.

This award recognizes individuals who demonstrate exceptional leadership in all facets of the program, including academic performance, project leadership and team management performance, professional development, and peer assessment.

Congratulations to Kevin Shipp of Y-12 Engineering; he was awarded the 2020 Sandia National Laboratories Weapon Intern Program Leadership Award. He is a graduate of the 2020 program, which was the 25th class.

This award recognizes individuals who demonstrate exceptional leadership in all facets of the program, including academic performance, project leadership and team management performance, professional development, and peer assessment.

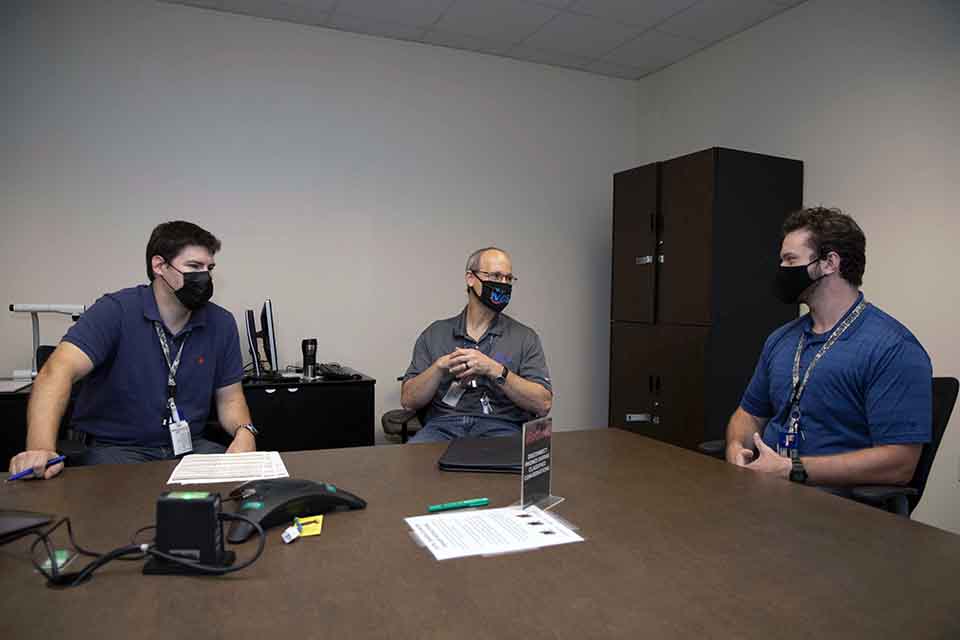

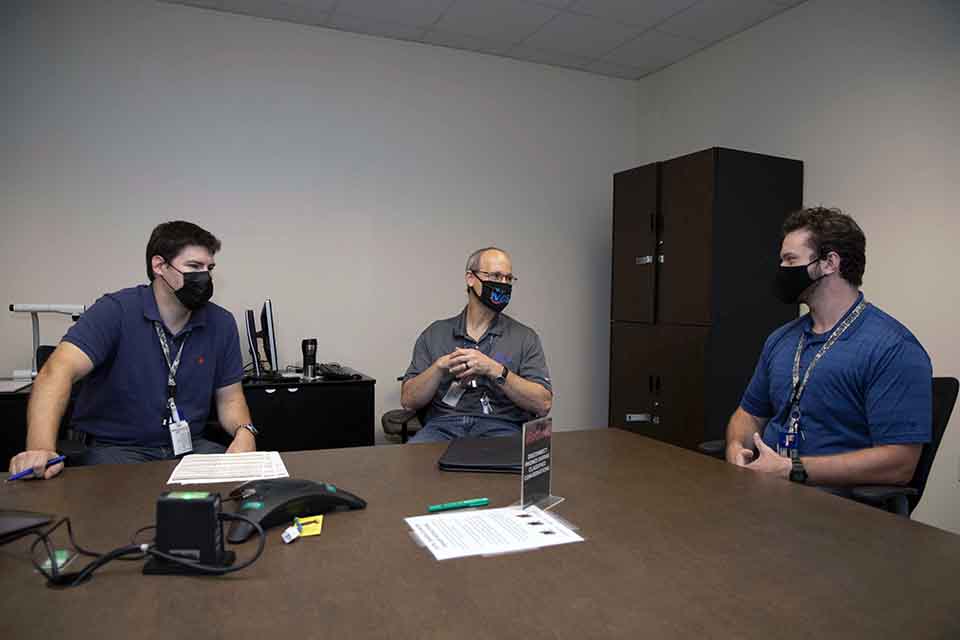

Joshua Schwartz (left), Chris Haught (center), and Dallas Moser discuss maintaining strict controls to ensure nuclear criticality safety.

Joshua Schwartz (left), Chris Haught (center), and Dallas Moser discuss maintaining strict controls to ensure nuclear criticality safety.

Take 5 minutes and learn more about Melissa Blair, CNS's new senior director of Enterprise Strategic Planning. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Take 5 minutes and learn more about Melissa Blair, CNS's new senior director of Enterprise Strategic Planning. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

Y-12 air condition and refrigeration mechanics, from left, stand beside the crimping tool (on top of an air conditioning unit) that allows the team to work more safely and efficiently.

Where do the best ideas come from? At Y-12, they often spring from the “voice from the floor,” from those who are closest to the work.

Y-12 air condition and refrigeration mechanics, from left, stand beside the crimping tool (on top of an air conditioning unit) that allows the team to work more safely and efficiently.

Where do the best ideas come from? At Y-12, they often spring from the “voice from the floor,” from those who are closest to the work.

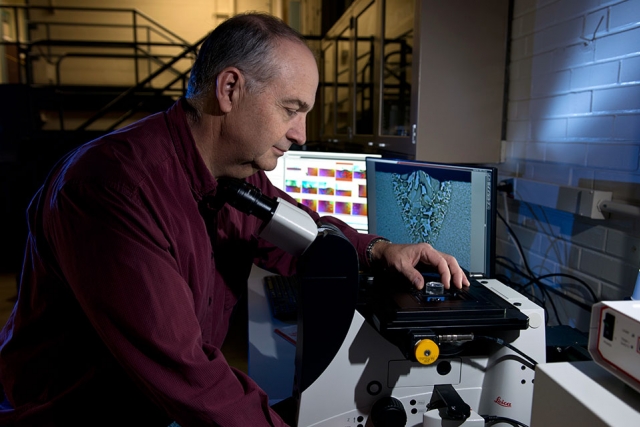

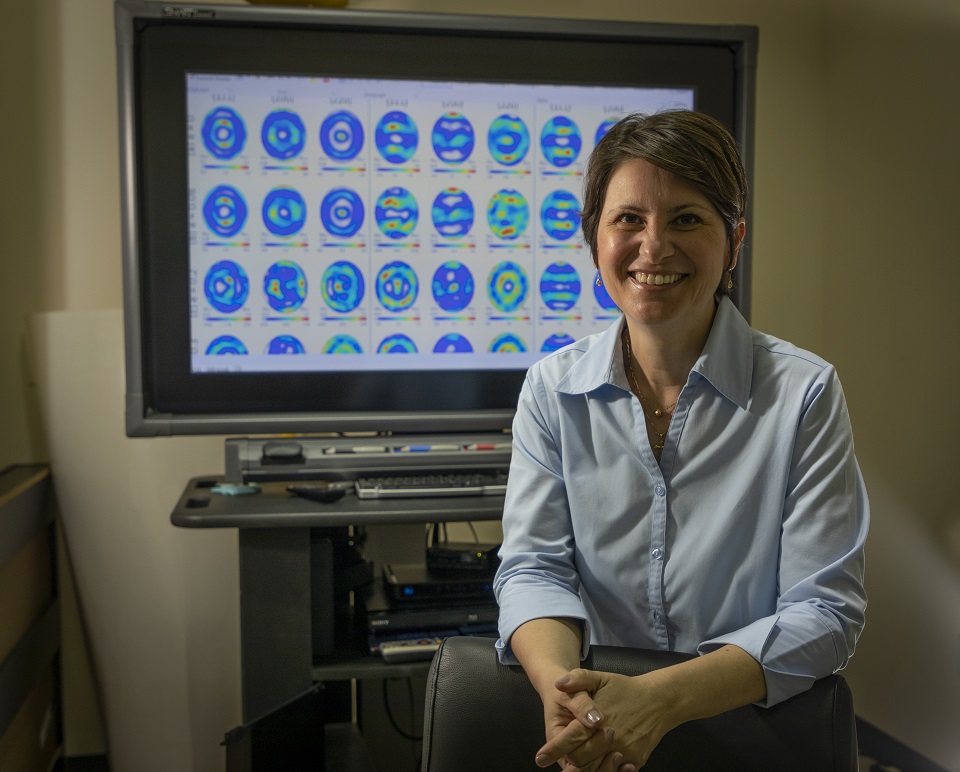

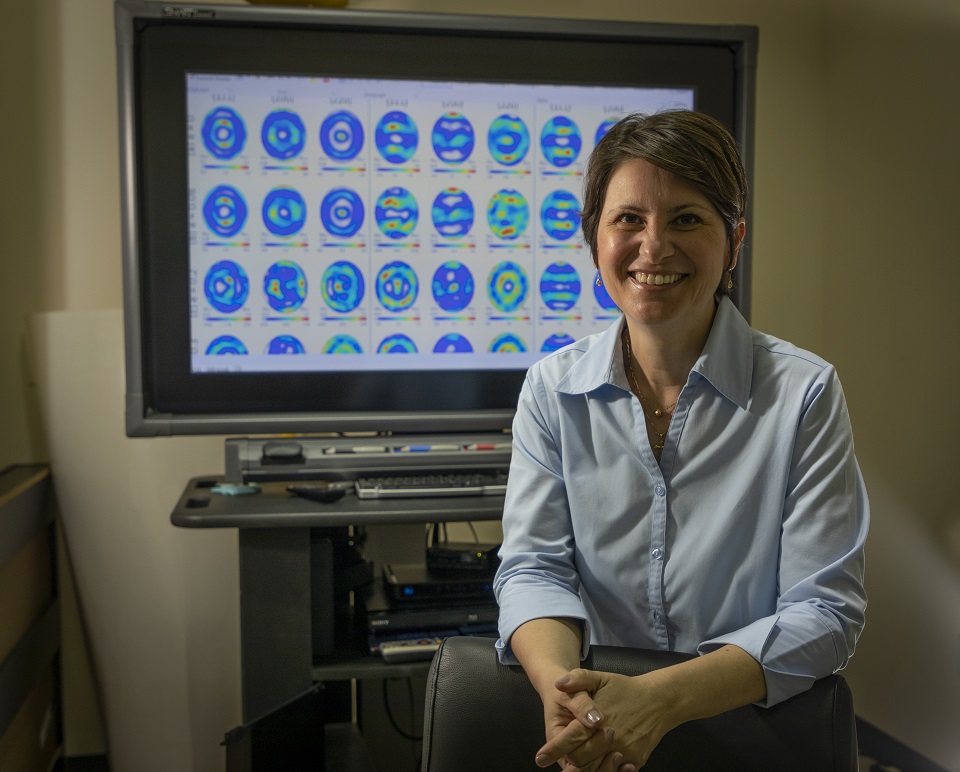

Elena Garlea’s work was recently published in Journal of Material Science and Engineering: AM as part of a larger effort carried out in collaboration with other NNSA sites and the University of Tennessee.

Elena Garlea’s work was recently published in Journal of Material Science and Engineering: AM as part of a larger effort carried out in collaboration with other NNSA sites and the University of Tennessee.

Through Tom Smith’s vision, strategic planning, and perseverance, the Pantex and Y‑12 skylines are forever changed.

Through Tom Smith’s vision, strategic planning, and perseverance, the Pantex and Y‑12 skylines are forever changed.

Karissa Sampson

Karissa Sampson is the 2020 Y-12 recipient of the Jackie Kelly Award for Administrative Excellence.

Karissa was nominated by her supervisor Kevin Corbett, who is director of the CNS Quality organization.

Karissa Sampson

Karissa Sampson is the 2020 Y-12 recipient of the Jackie Kelly Award for Administrative Excellence.

Karissa was nominated by her supervisor Kevin Corbett, who is director of the CNS Quality organization.

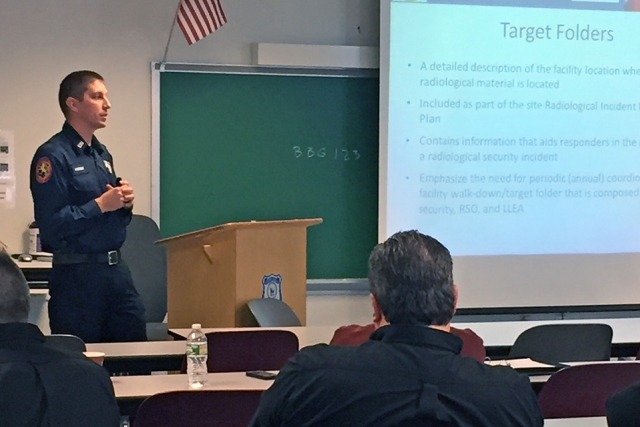

An Alarm Response Training instructor helps facilitate distance Alarm Response Training, or dART, to Northwestern Medicine Cancer Center during a class.

An Alarm Response Training instructor helps facilitate distance Alarm Response Training, or dART, to Northwestern Medicine Cancer Center during a class.

Due to support from the CNS Community Investment Fund, Keystone can still provide for their participants at home.

Due to support from the CNS Community Investment Fund, Keystone can still provide for their participants at home.

Due to support from the CNS Community Investment Fund, Keystone can still provide for their participants at home.

Due to support from the CNS Community Investment Fund, Keystone can still provide for their participants at home.

Y-12 continued vital projects throughout the COVID-19 response thanks to planning and teamwork. To ensure projects remained on track and on time, team members took that strong plan and coupled it with adherence to essential health and safety protocols.

Y-12 continued vital projects throughout the COVID-19 response thanks to planning and teamwork. To ensure projects remained on track and on time, team members took that strong plan and coupled it with adherence to essential health and safety protocols.

More than 1,400 employees are members of the Atomic Trades and Labor Council. Without these dedicated workers, Y-12 would have difficulty meeting its mission.

More than 1,400 employees are members of the Atomic Trades and Labor Council. Without these dedicated workers, Y-12 would have difficulty meeting its mission.

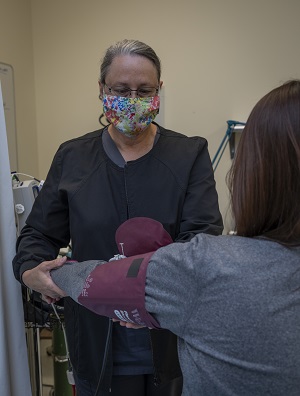

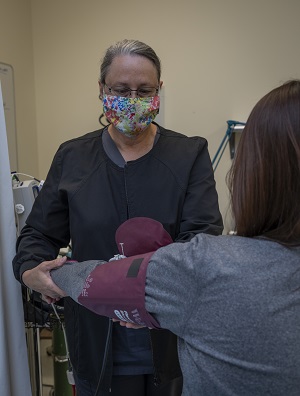

Y-12 nurse Denise Howard checks an employee’s blood pressure. |

Y-12 nurse Denise Howard checks an employee’s blood pressure. |

Y-12 nurse Denise Howard checks an employee’s blood pressure. |

Students who participated in the Y-12 Cybersecurity Camps, in partnership with Roane State Community College, experienced camp online, a new way of holding summer camp this year. The event was planned to be held at the RSCC Oak Ridge campus, but because of the COVID 19 pandemic, the camp became a virtual one.

Dr. George Meghabghab, director of the RSCC Computer Information Technology program, said, “Participation was great! Everybody was attentive, and it was fun and engaging.”

Students who participated in the Y-12 Cybersecurity Camps, in partnership with Roane State Community College, experienced camp online, a new way of holding summer camp this year. The event was planned to be held at the RSCC Oak Ridge campus, but because of the COVID 19 pandemic, the camp became a virtual one.

Dr. George Meghabghab, director of the RSCC Computer Information Technology program, said, “Participation was great! Everybody was attentive, and it was fun and engaging.”

In celebration of World Photography Day, take a look into the world of Y-12 through the lens of Brett Pate, one of the site’s professional photographers. He documents National Nuclear Security Administration mission activities as well as captures images for publications, visits, events, and conferences.

He’s been involved in photography for about 45 years, with 29 of those years working as a Y-12 photographer.

In celebration of World Photography Day, take a look into the world of Y-12 through the lens of Brett Pate, one of the site’s professional photographers. He documents National Nuclear Security Administration mission activities as well as captures images for publications, visits, events, and conferences.

He’s been involved in photography for about 45 years, with 29 of those years working as a Y-12 photographer.

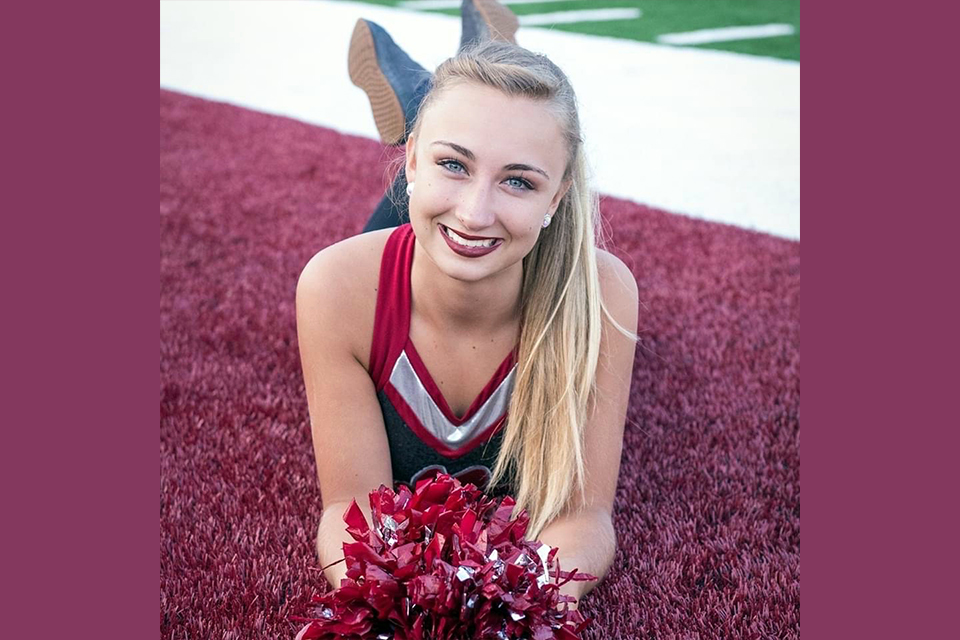

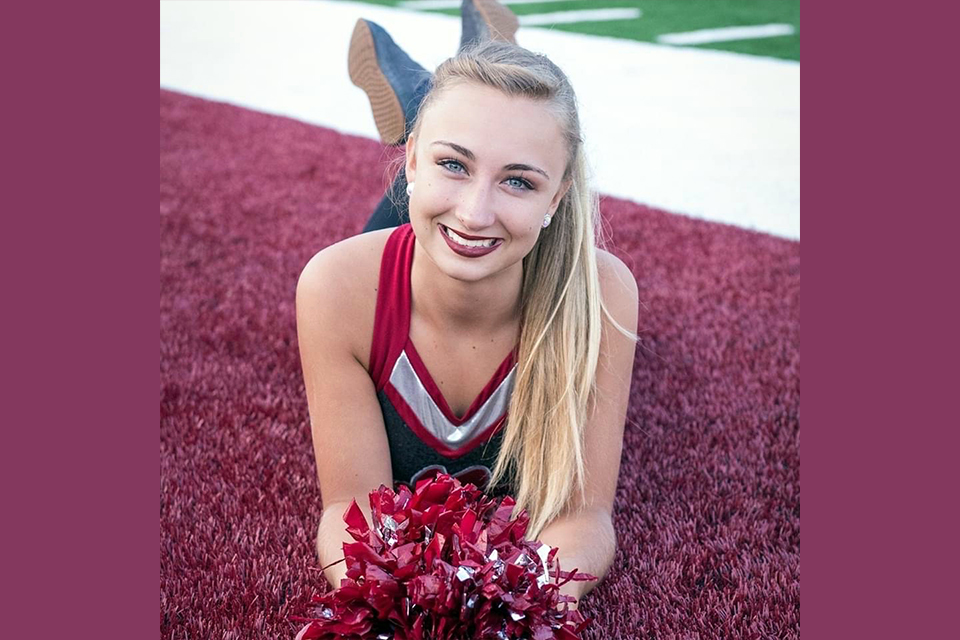

Josie Fellers

Josie Fellers

|

It is news that no parent or family is prepared for. In the wake of a global pandemic, Y-12’s John Fellers’ world had turned upside down.

Josie Fellers

Josie Fellers

|

It is news that no parent or family is prepared for. In the wake of a global pandemic, Y-12’s John Fellers’ world had turned upside down.

Y-12 has an improved fire protection system after employees recently completed an extensive eight year plant wide effort to replace more than 9,850 sprinkler heads in six site facilities.

Completion of the $46 million 50 year safety-significant sprinkler head replacement project means that those facilities can continue to meet fire protection requirements. The replacements reduce the risk of the site’s fire protection systems from high to low risk and improve Y-12’s long term operations capability.

Y-12 has an improved fire protection system after employees recently completed an extensive eight year plant wide effort to replace more than 9,850 sprinkler heads in six site facilities.

Completion of the $46 million 50 year safety-significant sprinkler head replacement project means that those facilities can continue to meet fire protection requirements. The replacements reduce the risk of the site’s fire protection systems from high to low risk and improve Y-12’s long term operations capability.

Y-12 completed the suspension and resumption of all operating areas, including canned subassembly production for the B61-12 program, within a six week window. |

Y-12 completed the suspension and resumption of all operating areas, including canned subassembly production for the B61-12 program, within a six week window. |

In recognition of working 30 days without a recordable injury at Y-12, the Site Manager’s Safety Council’s Safety Challenge for Charity donated $500 to extend community relief from COVID-19, in partnership with the East Tennessee Foundation’s Neighbor to Neighbor Disaster Relief Fund. Inspired by the act, ETF’s employees also came together to match Y-12’s donation.

In recognition of working 30 days without a recordable injury at Y-12, the Site Manager’s Safety Council’s Safety Challenge for Charity donated $500 to extend community relief from COVID-19, in partnership with the East Tennessee Foundation’s Neighbor to Neighbor Disaster Relief Fund. Inspired by the act, ETF’s employees also came together to match Y-12’s donation.

Mission Engineering is led by Gary Sanders, who has a wealth of experience within the nuclear weapons complex. |

Mission Engineering is led by Gary Sanders, who has a wealth of experience within the nuclear weapons complex. |

Jim Zonar of Y-12 Development shares his experience as a TOPGUN pilot.

Jim Zonar of Y-12 Development shares his experience as a TOPGUN pilot.

Jim Zonar of Y-12 Development shares his experience as a TOPGUN pilot.

Cary Langham in his Y-12 office |

The United States flag that spans the wall of Cary Langham’s office has a singular purpose: to remind him of his responsibilities as a patriot.

Cary Langham in his Y-12 office |

The United States flag that spans the wall of Cary Langham’s office has a singular purpose: to remind him of his responsibilities as a patriot.

Jeff Yarbrough, Y-12 deputy site manager

Jeff Yarbrough’s expertise is rooted in ensuring the safety of our nation’s nuclear security. As Y-12 deputy site manager, it is his responsibility to provide an independent perspective in order to keep the site safe and secure from threats or abnormal conditions, including COVID-19.

Jeff Yarbrough, Y-12 deputy site manager

Jeff Yarbrough’s expertise is rooted in ensuring the safety of our nation’s nuclear security. As Y-12 deputy site manager, it is his responsibility to provide an independent perspective in order to keep the site safe and secure from threats or abnormal conditions, including COVID-19.

Jeff Yarbrough, Y-12 deputy site manager

Jeff Yarbrough’s expertise is rooted in ensuring the safety of our nation’s nuclear security. As Y-12 deputy site manager, it is his responsibility to provide an independent perspective in order to keep the site safe and secure from threats or abnormal conditions, including COVID-19.

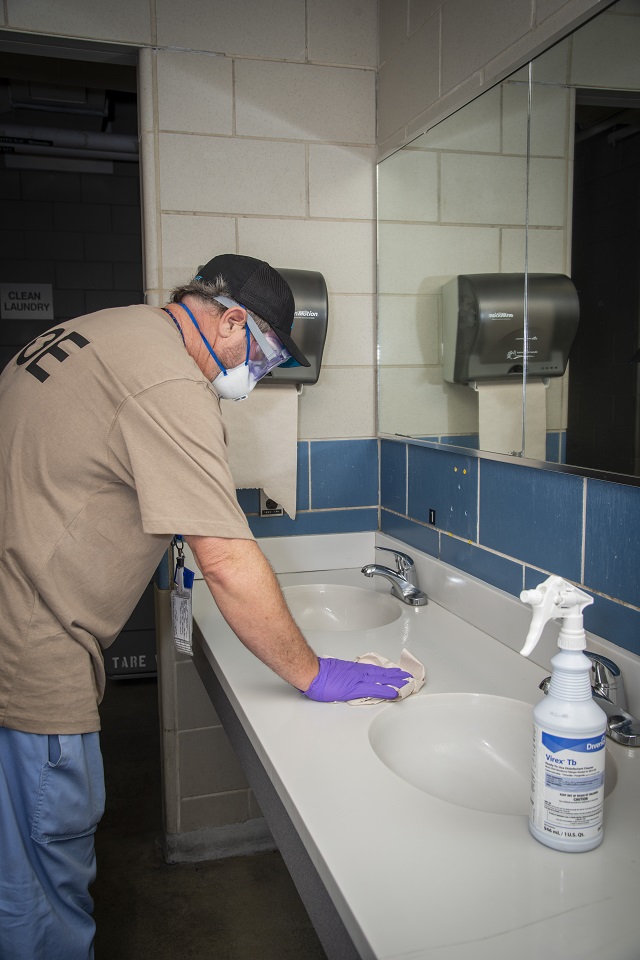

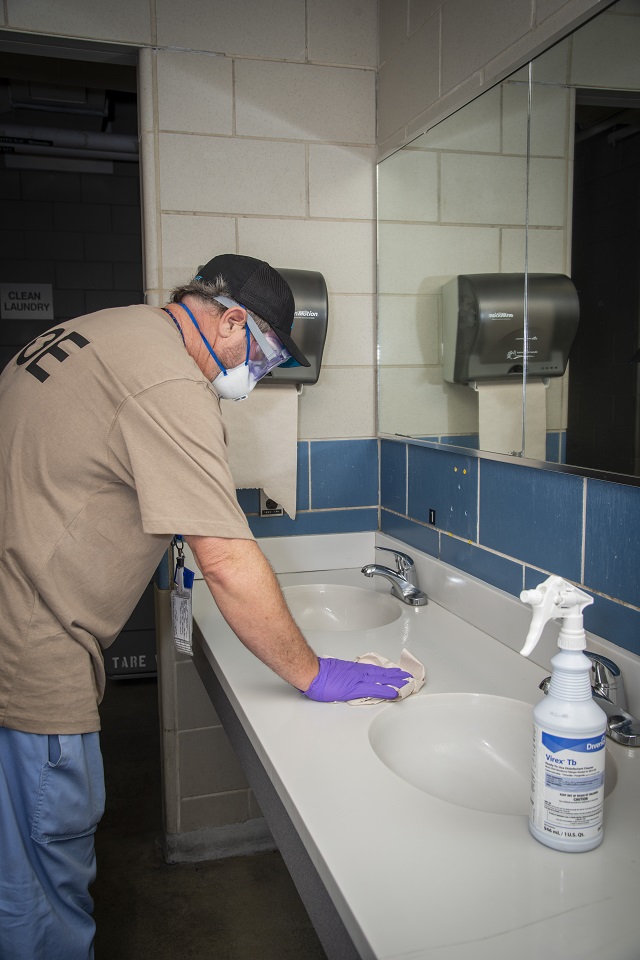

Y-12 Building Services and Lawler-Wood Maintenance and Facilities Technicians continue to disinfect commonly used areas and ensure their safety using face masks and gloves. |

Y-12 Building Services and Lawler-Wood Maintenance and Facilities Technicians continue to disinfect commonly used areas and ensure their safety using face masks and gloves. |

Y‑12 archivist Natalie Hansen recently obtained her digital archivist certification. She is already a certified archivist, but this newest certificate covers digital archiving in a more focused and specialized manner.

Y‑12 archivist Natalie Hansen recently obtained her digital archivist certification. She is already a certified archivist, but this newest certificate covers digital archiving in a more focused and specialized manner.

In late winter, Roane State Community College partnered with Y-12 to develop a new Cybersecurity Summer Camp for middle and high school students. What started as an in person camp to be held Roane State’s Oak Ridge Branch Campus will now be a virtual camp due to the COVID 19 pandemic.

In late winter, Roane State Community College partnered with Y-12 to develop a new Cybersecurity Summer Camp for middle and high school students. What started as an in person camp to be held Roane State’s Oak Ridge Branch Campus will now be a virtual camp due to the COVID 19 pandemic.

In response to the COVID-19 pandemic, many employees from both Y-12 and Pantex have become “mask makers” using their skills and talents behind a sewing machine to make masks for their friends,

neighbors and coworkers.

Pantexan Charlotte Thomas and her husband Brian Thomas |

In response to the COVID-19 pandemic, many employees from both Y-12 and Pantex have become “mask makers” using their skills and talents behind a sewing machine to make masks for their friends,

neighbors and coworkers.

Pantexan Charlotte Thomas and her husband Brian Thomas |

Two electrical distribution system projects at Y 12 include an unlikely trio: grandfather, father, and son. Edward, Justin, and Justin, Jr. Cagle work on 13.8kv Electrical Distribution System Installation for 2nd and 3rd Streets where the linemen — all three of them — are replacing and installing utility poles and electrical conductors.

Two electrical distribution system projects at Y 12 include an unlikely trio: grandfather, father, and son. Edward, Justin, and Justin, Jr. Cagle work on 13.8kv Electrical Distribution System Installation for 2nd and 3rd Streets where the linemen — all three of them — are replacing and installing utility poles and electrical conductors.

For more than 10 years, the Y-12 Apprenticeship Program has been in business, training employees for professions in trades like pipefitters, electricians, machinists, and ironworkers. The program, restarted in 2008 as a cost savings proposal, allows hands-on training for key positions within the site.

For more than 10 years, the Y-12 Apprenticeship Program has been in business, training employees for professions in trades like pipefitters, electricians, machinists, and ironworkers. The program, restarted in 2008 as a cost savings proposal, allows hands-on training for key positions within the site.

Y-12ers have stepped up to support one of our own, Y-12 Engineering’s Tony Grappin, whose son was diagnosed with leukemia. |

Y-12ers have stepped up to support one of our own, Y-12 Engineering’s Tony Grappin, whose son was diagnosed with leukemia. |

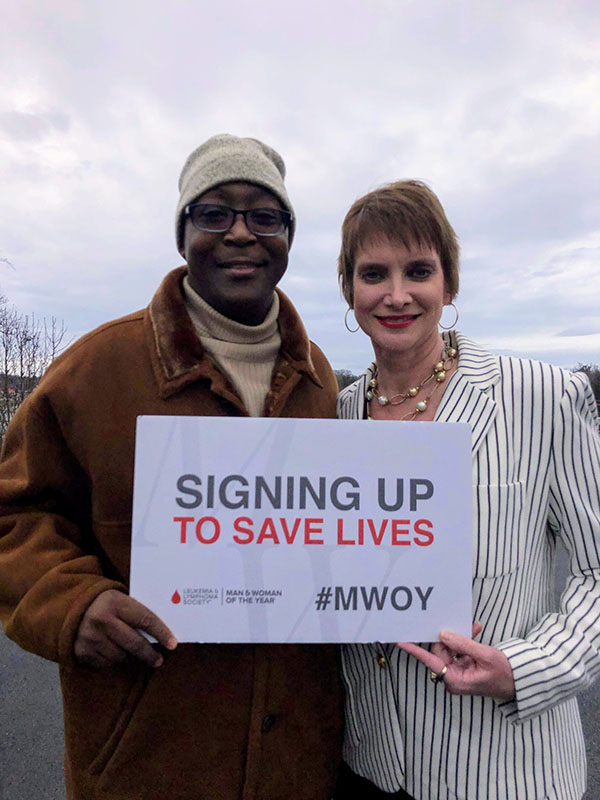

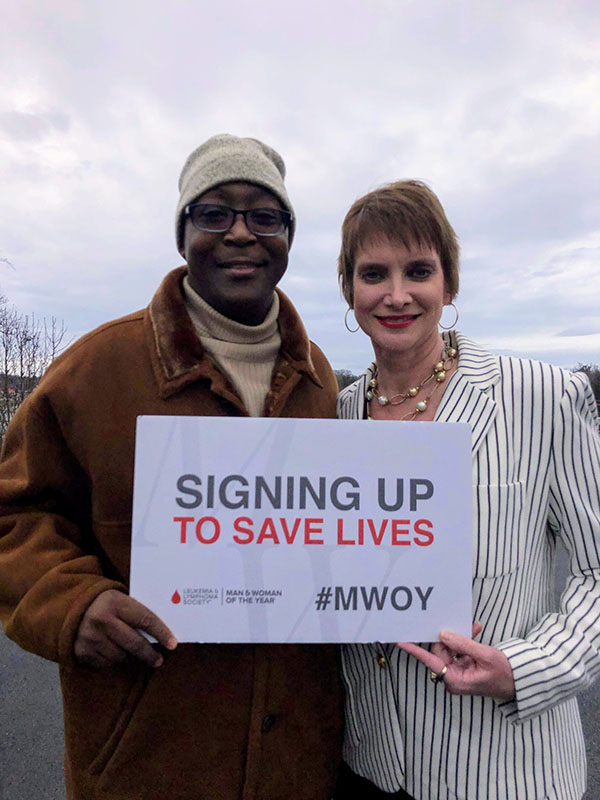

Y-12 employees Tony and Barbie White

Y-12 employees Tony and Barbie White

He’s a beloved member of the Y-12 family who bleeds orange and is a University of Tennessee Vol for Life. Now, Tony White, Protective Force Operations, is up for the Leukemia and Lymphoma Society’s Man of the Year and shared the following.

Y-12 employees Tony and Barbie White

Y-12 employees Tony and Barbie White

He’s a beloved member of the Y-12 family who bleeds orange and is a University of Tennessee Vol for Life. Now, Tony White, Protective Force Operations, is up for the Leukemia and Lymphoma Society’s Man of the Year and shared the following.

Y-12 employee Meghann Parrilla was named a 2019 40 Under 40 honoree by Knox.biz magazine. |

Y-12 employee Meghann Parrilla was named a 2019 40 Under 40 honoree by Knox.biz magazine. |

Y-12 employee Meghann Parrilla was named a 2019 40 Under 40 honoree by Knox.biz magazine. |

Scott Underwood, Senior Director of Y-12 Infrastructure, addresses volunteers at the most recent Help the Smokies Day.

Scott Underwood, Senior Director of Y-12 Infrastructure, addresses volunteers at the most recent Help the Smokies Day.

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months.

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months.

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months.

Transformation at the Uranium Processing Facility Main Process Building (MPB) has accelerated in the past few months.

How do you go about adding 800 new storage locations to an already in place building? It’s a project that a team is tackling now at the Highly Enriched Uranium Materials Facility as they add more storage space for rackable can storage boxes.

How do you go about adding 800 new storage locations to an already in place building? It’s a project that a team is tackling now at the Highly Enriched Uranium Materials Facility as they add more storage space for rackable can storage boxes.

At the Y-12 National Security Complex, you won’t find employees lurking around in trench coats, but for intern Colleen Hyer, the site does hint of intrigue.

At the Y-12 National Security Complex, you won’t find employees lurking around in trench coats, but for intern Colleen Hyer, the site does hint of intrigue.

“The biggest benefit of Apollo was the inspiration it gave to a growing generation to get into science and aerospace.” – Buzz Aldrin, Lunar Module Pilot, Apollo 11

“The biggest benefit of Apollo was the inspiration it gave to a growing generation to get into science and aerospace.” – Buzz Aldrin, Lunar Module Pilot, Apollo 11

There are 1,500 new faces at CNS, and they all arrived in 2018.

Last year CNS was busy building the workforce for the future at Pantex and Y-12. Recruiting the next generation of professionals to support national security is one of the top priorities for the Nuclear Security Enterprise.

There are 1,500 new faces at CNS, and they all arrived in 2018.

Last year CNS was busy building the workforce for the future at Pantex and Y-12. Recruiting the next generation of professionals to support national security is one of the top priorities for the Nuclear Security Enterprise.

More than 100 CNS employees were among the thousands of runners who took part in 5K, Half, Relay, and Marathon races at this year’s Covenant Health Knoxville Marathon.

More than 100 CNS employees were among the thousands of runners who took part in 5K, Half, Relay, and Marathon races at this year’s Covenant Health Knoxville Marathon.

UPF celebrated the placement of the last piece of the structural frame of the Mechanical Electrical Building on Feb. 11.

UPF celebrated the placement of the last piece of the structural frame of the Mechanical Electrical Building on Feb. 11.

Steel installation for the second level of the Uranium Processing Facility’s (UPF) Mechanical Electrical Building (MEB) began in late December.

Steel installation for the second level of the Uranium Processing Facility’s (UPF) Mechanical Electrical Building (MEB) began in late December.

Tennessee Governor Bill Haslam appointed Syreeta Vaughn to the University of Tennessee, Knoxville, Advisory Board in December.

Tennessee Governor Bill Haslam appointed Syreeta Vaughn to the University of Tennessee, Knoxville, Advisory Board in December.

Additive manufacturing isn’t new to CNS, but three new machines recently found their home in a Y-12 production facility, and that location is new.

Additive manufacturing isn’t new to CNS, but three new machines recently found their home in a Y-12 production facility, and that location is new.

Congratulations to the newest Y‑12 Security Police Officers.

Congratulations to the newest Y‑12 Security Police Officers.

Katie Roberts, of Y-12’s Supply Chain Management was recently named one of Knox.biz magazine’s 40 Under 40 honorees and will be recognized at an awards ceremony in January.

Katie Roberts, of Y-12’s Supply Chain Management was recently named one of Knox.biz magazine’s 40 Under 40 honorees and will be recognized at an awards ceremony in January.

The Uranium Processing Facility (UPF) is placing concrete twice per week for the structural foundation of the Main Process Building (MPB). The placements began on Sept. 11.

The Uranium Processing Facility (UPF) is placing concrete twice per week for the structural foundation of the Main Process Building (MPB). The placements began on Sept. 11.

The Uranium Processing Facility (UPF) is placing concrete twice per week for the structural foundation of the Main Process Building (MPB). The placements began on Sept. 11.

It’s a go.

Y-12 recently received the Qualification Evaluation Release for the B61-12 Life Extension Program canned subassembly. Receiving this QER was the final step to authorize CNS to begin manufacturing and delivery of the program’s first production unit, scheduled for March 2019.

It’s a go.

Y-12 recently received the Qualification Evaluation Release for the B61-12 Life Extension Program canned subassembly. Receiving this QER was the final step to authorize CNS to begin manufacturing and delivery of the program’s first production unit, scheduled for March 2019.

It’s a go.

Y-12 recently received the Qualification Evaluation Release for the B61-12 Life Extension Program canned subassembly. Receiving this QER was the final step to authorize CNS to begin manufacturing and delivery of the program’s first production unit, scheduled for March 2019.

How often do you think about the items you purchase and use daily — everything from paper to coffee to cleaning supplies? Where do they come from? How are they made? Are they good for the environment?

How often do you think about the items you purchase and use daily — everything from paper to coffee to cleaning supplies? Where do they come from? How are they made? Are they good for the environment?

How often do you think about the items you purchase and use daily — everything from paper to coffee to cleaning supplies? Where do they come from? How are they made? Are they good for the environment?

How often do you think about the items you purchase and use daily — everything from paper to coffee to cleaning supplies? Where do they come from? How are they made? Are they good for the environment?

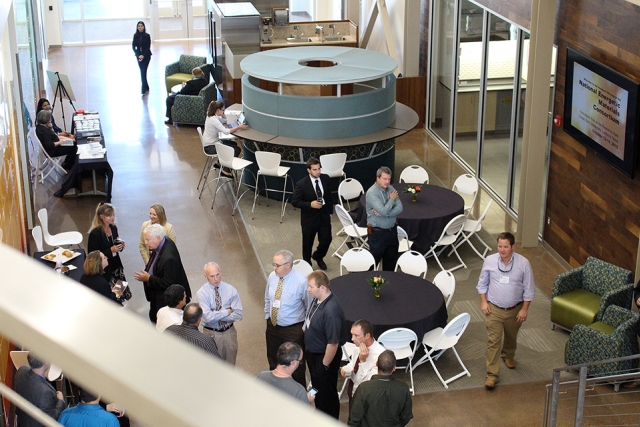

The NBL Center was officially opened June 11, with about 50 representatives from the Nuclear Security Enterprise and Y‑12 in attendance.

The NBL Center was officially opened June 11, with about 50 representatives from the Nuclear Security Enterprise and Y‑12 in attendance.

The NBL Center was officially opened June 11, with about 50 representatives from the Nuclear Security Enterprise and Y‑12 in attendance.

The NBL Center was officially opened June 11, with about 50 representatives from the Nuclear Security Enterprise and Y‑12 in attendance.

Y-12’s 75th Anniversary recently received some significant attention close to home and in Washington, D.C.

Y-12’s 75th Anniversary recently received some significant attention close to home and in Washington, D.C.

Almost 200 people representing 120 businesses attended a Partners in Excellence Forum hosted by Consolidated Nuclear Security, LLC.

Almost 200 people representing 120 businesses attended a Partners in Excellence Forum hosted by Consolidated Nuclear Security, LLC.

Almost 200 people representing 120 businesses attended a Partners in Excellence Forum hosted by Consolidated Nuclear Security, LLC.

In less than five years, the Uranium Processing Facility (UPF) Project has recycled or reused nearly 194 million pounds of materials and diverted more than 97 percent of the project’s total waste from landfills.

“Our recycling and reuse effort is the result of careful planning prior to the beginning of construction,” said UPF Project Director John Howanitz.