Y-12 Blog

Radiation is all around us. The sun, the earth, and other sources all emit radiation. At Y‑12 National Security Complex, radiation exposures are equivalent to what you get from nature.

In 2022, for a fourth year in a row, no one at Y‑12 received a dose of more than 350 millirem.

That’s a significant milestone, so much so that Dr. Marvin Adams, NNSA deputy administrator for Defense Programs, noted Y‑12’s achievement to NNSA Nuclear Production Office and Y‑12 site leadership during his visit in early June.

By comparison, a person receives an average annual dose from natural and manmade sources of roughly 620 mrem, or 310 mrem from radon in the air, cosmic rays, and earth materials and 310 mrem from medical, commercial, and industrial sources each year.

The importance of the achievement is obvious. When our bodies are exposed to radiation, they interact at the cellular level. The result of a radiological exposure can range from no damage, to, in the extreme, cancer. The exact effect depends on the specific type and intensity of the radiation exposure. Reducing exposures is a health and safety issue, which is why radiological protection is such an important priority at Y‑12.

The regulatory exposure limit is 5,000 mrem. Y‑12’s milestone shows the level of commitment to safety, by keeping exposure as low as reasonably achievable (ALARA). That means ALARA has resulted in exposures that are less than 10% of what is allowed regulatorily.

“All in all, 2022 was an outstanding year for radiological work,” said Scott Wical, Radiological Control manager.

Y‑12 Deputy Site Manager Jan West, who served as senior director of Safety and Industrial Hygiene, was pleased with the numbers. “These rates don’t happen by accident,” she said. “Team commitment to continuously improve the radiological conditions, controls, and work practices is key to our success. It takes everyone doing their part,” she added.

Coming in contact with contaminated surfaces is one of the most challenging aspects of performing radiological work. At the encouragement of Y‑12 Site Manager Gene Sievers, the team made great strides in reducing contamination in work areas.

“Reducing removable contamination from work areas lessens the amount of activity that can become airborne and be breathed in by individuals when conducting work,” Wical said.

That and other efforts to reduce radiation exposures could not have been achieved without a total team effort, including the following:

- Y‑12 senior management

- NNSA Production Office

- RADCON Infrastructure Sustainment

- Program Management

- Facility Operations Management

- Clean Sweep and Sustainment

- Rad workers, planners, engineers, instructors, and supervisors

- ALARA committee members

- Safety and Industrial Hygiene

- RADCON personnel

Wical says he is “blessed and happy” to be part of this successful effort but realizes that the work is never done. “It starts on the floor with our Production folks and with our managers and supervisors,” he said. “It takes everybody’s commitment, and I’m humbled to be part of it.”

At Y-12 National Security Complex, the landscape continues to transform. The latest new facility to begin operations is a state-of-the-art fire station.

Construction began in the spring of 2021 after 20 years of discussion and planning. When visiting the new Y-12 Fire Station in January of this year, NNSA Administrator Jill Hruby described it as a model construction project for NNSA and the Nuclear Security Enterprise.

On July 24, the Y-12 Fire Department officially moved in, making the station fully operational.

“The new facility will improve our department’s ability to serve the plant and our community,” said Fire Chief James Arnold.

The old fire station building, which was originally constructed in the 1940s and expanded in the ‘60s and ‘80s, has a lot of issues according to Chief Arnold and the firefighters who have used the facility.

“We’ve had to live with some rough conditions for a while,” said Y-12 Fire Department Captain Mike Jeffries, a 17-year veteran of Y-12.

“How do I feel about the move to our new fire hall?” Jeffries asked. He smiled. “I’m happy.”

“The upgraded firehouse will not only improve the working environment for our firefighters but also their lifestyle as it will allow us to transition to a more traditional firefighter schedule. It will also house better and more effective equipment,” said Chief Arnold.

The new fire station is one of two NNSA pilot projects at Y-12 designed to streamline the efficiencies and delivery of construction projects under $50 million. The second project was the newly-constructed Emergency Operations Center.

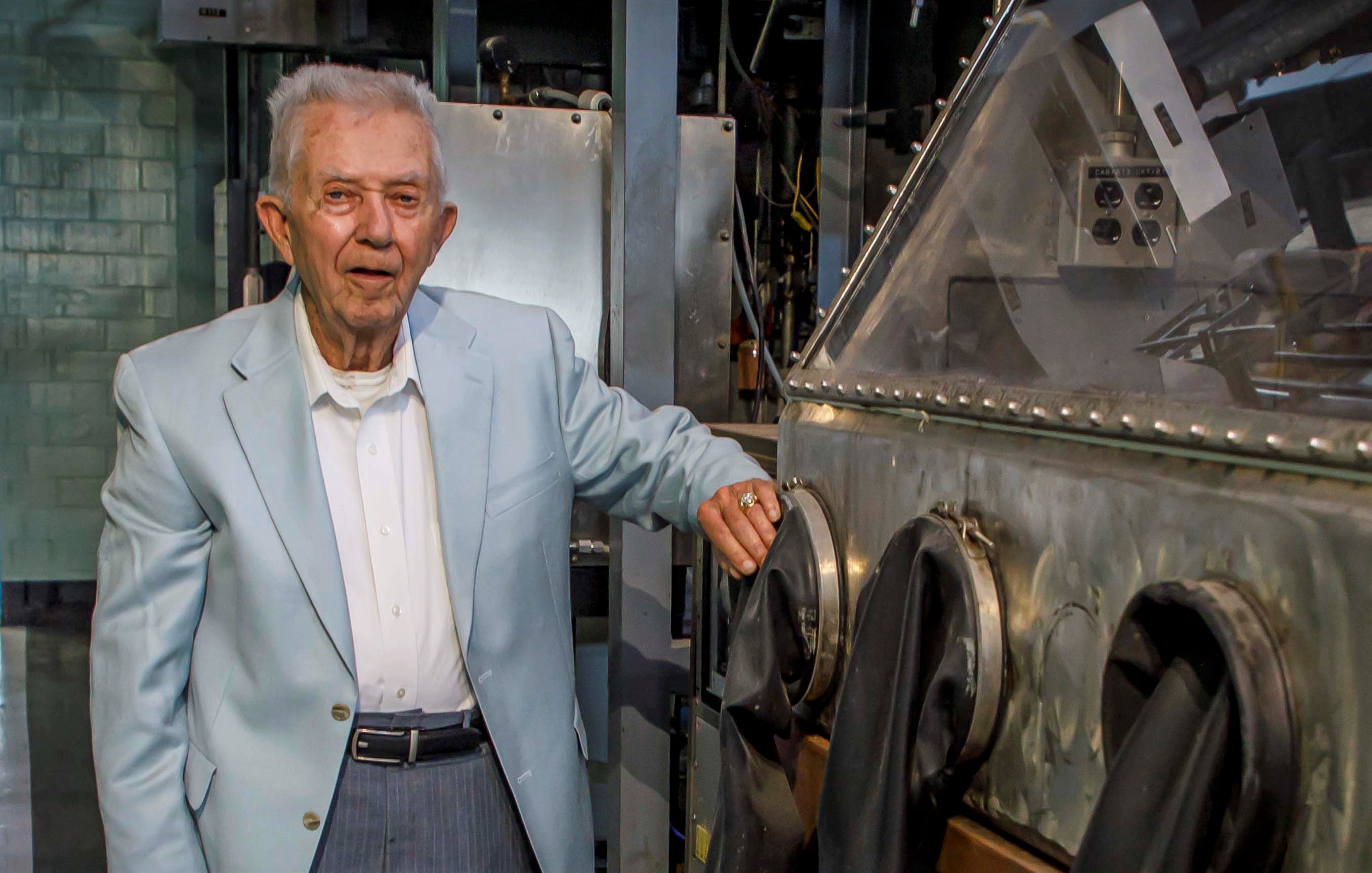

Bill Clark poses next to a glove box similar to one he worked with in the 1950’s

June 16, 1958: a day that is seared into Y-12’s history as the nation’s first nuclear criticality accident in a process facility. As the only remaining survivor of this accident, Bill Clark, now 90 years old, remembers it distinctly, and he recently returned to Y-12 for the first time since the mid-1960’s to share his story and to see how far the site has come in preventing similar accidents.

In 1958, Clark (referred to as “Employee H” in reports) worked as a chemical operator in the C1 Wing of Building 9212. On the day of the event, he was assigned to operate four EK evaporators approximately 50 feet from where the criticality occurred. Unbeknownst to him and others working that day, uranyl nitrate had been leaking through a valve in a temporary line connecting B1 and C1 wings.

At the time of the event, approximately 2:05 p.m., operators in C1 Wing were finishing an extensive inventory and cleanout process that took multiple shifts to complete. The final step before placing the system back into operation was to drain leak-test water from the pipes and safe tanks. However, the uranyl nitrate that had been leaking into the overhead pipes from B1 drained first, instead of water.

Clark recalls the moment the solution reached a sufficient level to react.

“I saw lightning bars zip-zip-zip across the ceiling going every which way,” he said. “I thought it was the welders and didn’t think anything of it. Then a fog started to descend in the room and the most God awful smell you can think of—worse than rotten eggs. That’s when the alarms went off.”

Clark’s story, and his return to Y-12, provide a stark reminder of the hazardous materials used every day across the Nuclear Security Enterprise—and the safety changes that have been put in place to prevent something similar from occurring today.

“The 1958 accident was an unfortunate event, but we learned a lot from it,” CNS Chief Nuclear Criticality Engineer Chris Haught said. “First and foremost we learned to keep large geometries out of areas where we process enriched uranium solutions. We also learned the importance of procedural control and conduct of operations. Most importantly, we learned to evaluate minor events and implement corrective actions to prevent a major event.” Fortunately for Clark he exited out the back door of C1 Wing instead of leaving his normal route, which would have taken him directly past the drum.

Everyone was instructed to start walking, Clark recalled, and they did not stop until reaching the Oak Ridge Skyway Drive-In Theater, roughly where Hobby Lobby is today. After sitting under a tree for multiple hours, Clark was instructed to get in line to have the film strip on his badge checked.

“That’s how they figured out where the accident happened,” Clark said. “We all started showing up with our film badges. I was 10 feet from the film checker when the meter hit the peg.”

It was that moment when Clark learned he had been exposed.

“I didn’t know I had been in a criticality when I was sitting under the tree,” he said. “I hadn’t felt nothing. I only knew what I had observed.”

Clark was rushed to the hospital for treatment.

“They gave me the most thorough scrub down of my life,” he said. “It felt like they were taking my skin off. They took blood from us. They took bone marrow from us.”

Exhaustive tests were done trying to determine how bad the accident was. In total, eight employees were exposed to high doses of radiation that day and all suffered long-term health effects including numerous forms of cancer. Clark endured multiple operations. To this day, he maintains a strict diet and takes a handful of medications every day to help him live. The radiation dosage levels received for each employee vary, but Clark accepts a 2002 estimate of 165 rem.

“We learned a lot of lessons from the 1958 accident,” Vice President of Mission Engineering Tony Boser said. “We’ve incorporated those lessons into our overall approach to safety at Y-12 through our procedures, our training, and in our engineering controls. All of these are designed to prevent another incident. But we can’t stop there. As we transform our site to meet our future mission demands, we are designing our facilities and our processes with the latest and most robust techniques to ensure safety in all aspects of our work. Both for our employees and our community at large.”

Following the interview, Clark re-lived his time at Y-12 with a tour of the plant. He shared stories of his work in Buildings 9201-4, 9201-5, 9204-2, and 9212. As a piece of advice to employees doing similar work today, Clark stressed the importance of wearing proper PPE.

Bill Clark is welcomed to Y-12 by NNSA Production Office employees nearly 65 years after being exposed to high levels of radiation during the 1958 Nuclear Criticality Accident.

Bill Clark recalls his experiences during the 1958 Nuclear Criticality Accident

Bill Clark tours Building 9731, the first building complete at the Y-12 National Security Complex in 1943.

Bill Clark discusses work he did in a glovebox similar to what was used during the 1950’s.

Bill Clark overlooks the Y-12 Plant while sharing stories of his work in various buildings

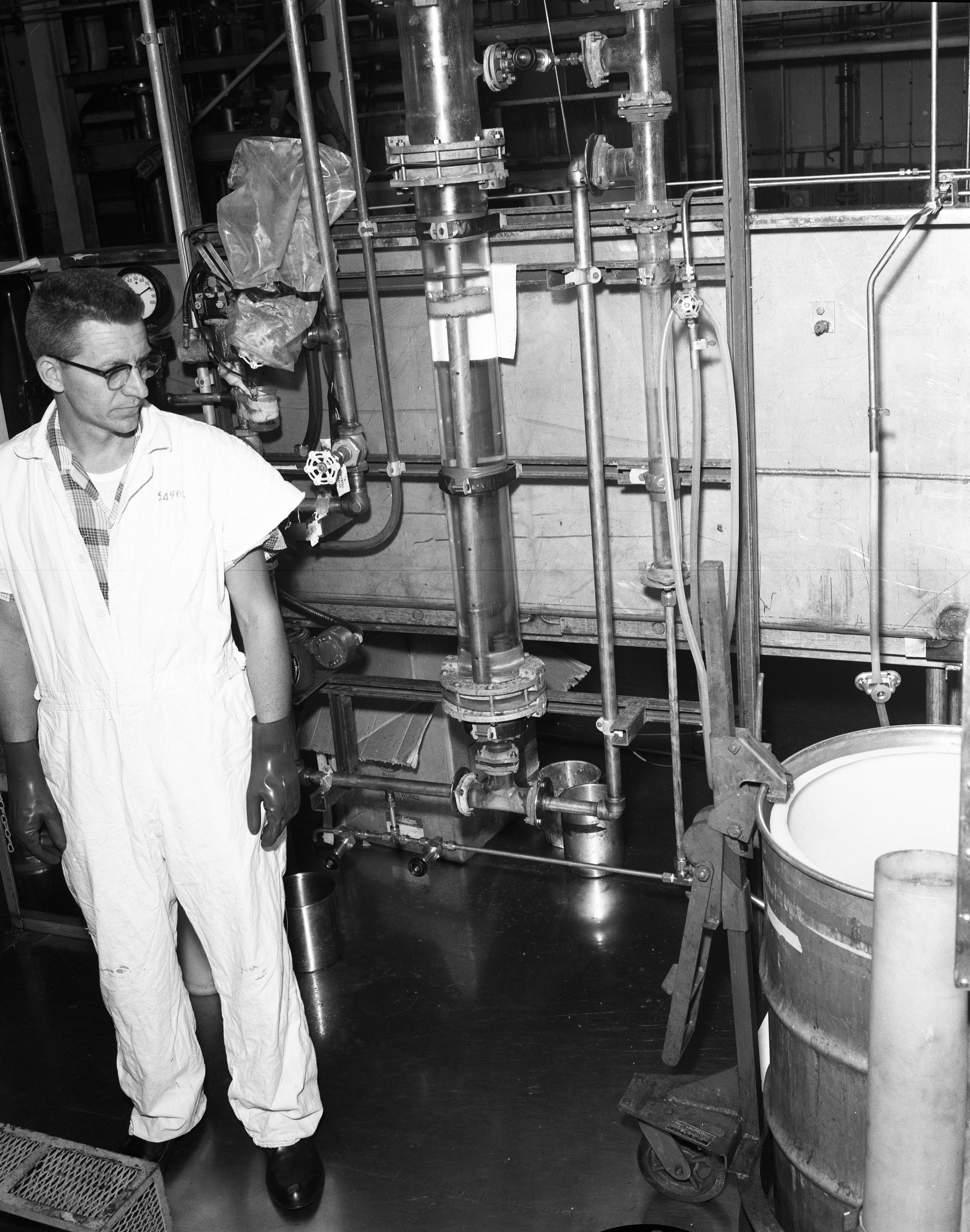

Building 9212 C1 Wing following the 1958 Nuclear Criticality Accident

Re-enactment of employee “A” position in proximity of the drum at the time of the incident.

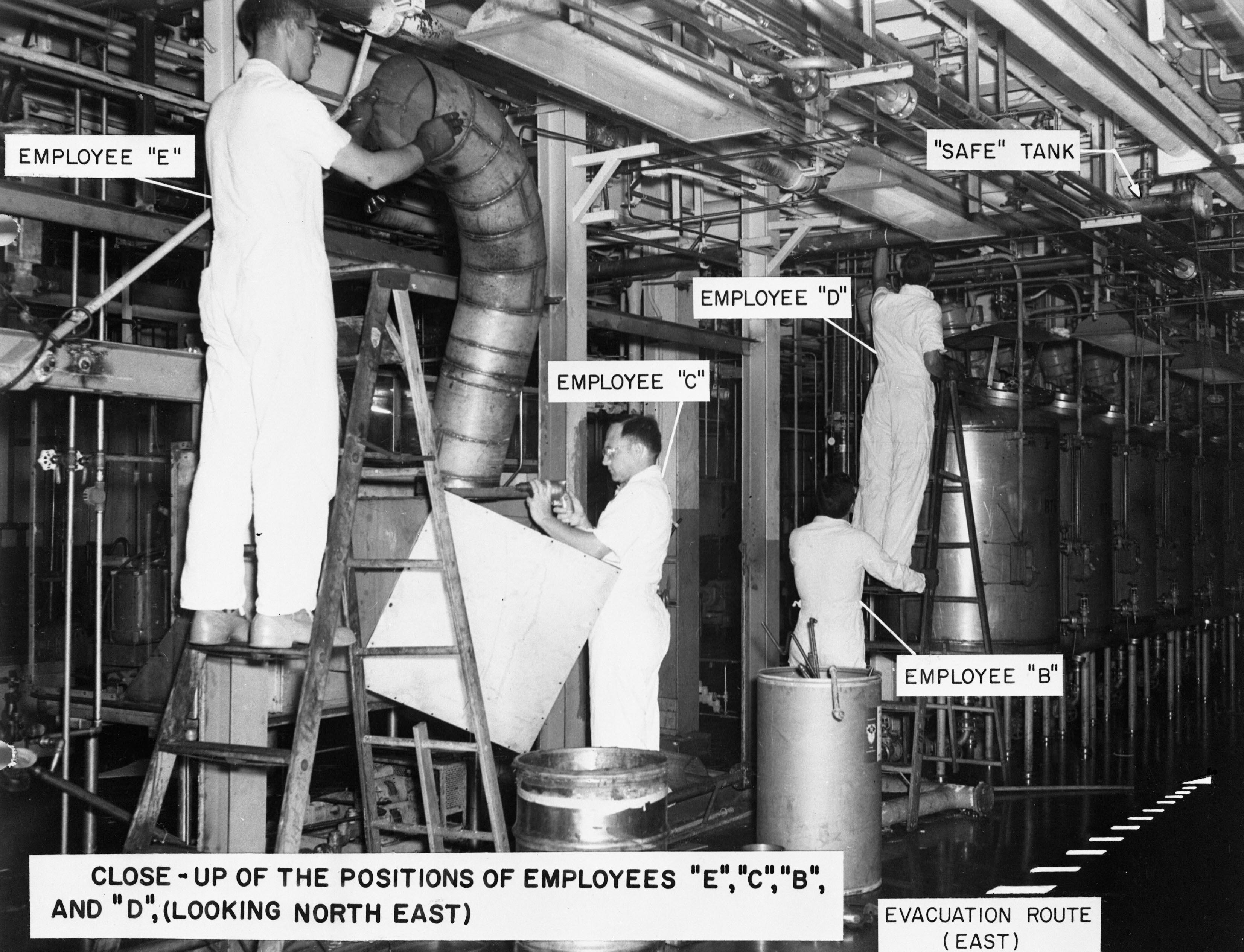

Re-enactment of positions employees in proximity of the drum at the time of the incident.

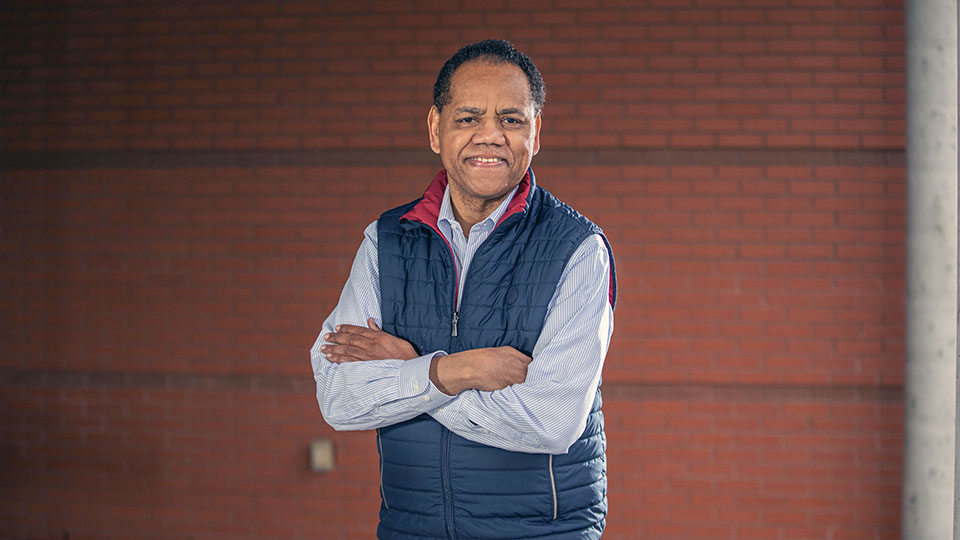

Jeff Hankins (center) now calls nearly two dozen of his former students coworkers.

Jeff Hankins has been a Y-12 certified welding inspector since 2021. He is considered a subject matter expert in the field of welding and weld inspection. His willingness and demonstrated ability to work with welders, inspectors, and engineers have made him a valued addition to the Y-12 team. However, he has had an impact at Y-12 long before he started coming through the gates each day.

It’s his interpersonal skills that set him apart, according to his supervisor, Donnie Cardwell, who said Hankins has a positive impact on everyone he meets.

“Jeff has a student-oriented teaching style and the ability to adjust his approach to suit the individual,” Cardwell said.

That teaching style is well earned. For years, Hankins taught welding at Oak Ridge High School. His former students number in the hundreds. At Y-12, more than 20 workers started their welding career paths learning from him in high school.

“I think I was meant to be a teacher. That is what I am,” Hankins said. “But I am a teacher who possesses other skills that enable me to earn a good living.”

Hankins said that his goal at Y-12 is to do as good a job as possible and that he is content where he is, although he admits he misses teaching. Cardwell and others who work with Hankins will tell you that he may not be a teacher by trade any longer, but he is still teaching.

Among his former students is Matthew Spangler, who works for Y-12 Infrastructure.

Spangler said he still remembers welding class and how Hankins was not just a teacher but also a father figure to him. Spangler’s father died when he was a young teen, and he admits he did not handle it well.

“I was on a downward spiral and running with a tough crowd,” Spangler said. “Jeff held me to a higher standard. He offered me a way out of the direction I was headed.”

More of Hankins’ former students who now work at Y-12 tell similar stories.

Brandon Collier, a production supervisor in Special Materials Operations, said, “His teaching style got through to a bunch of knuckleheaded kids with no sense of direction for where they wanted to be after high school.”

Another former student is Matthew Gwyn, who works as a welder. He said, “Wow, I could write a book on all of the moments and experiences I had with Jeff that led me to be the man I am today.

“There were so many of us in that class that had been forgotten and abandoned by the system, but Jeff saw us all as his kids, and we knew and felt it — even the troubled ones whose future was a drug overdose or jail. He showed us there was more to our lives than what we saw in our broken homes and that we could be better.”

Erica Heckman, a welder for East Mission Support, met Hankins when she was a freshman. She said Hankins was the one person in her life who believed in her.

“I was a kid in school who teachers said would never be successful because I was not a bookworm. But Mr. Hankins disagreed — and told me so,” Heckman said. “He encouraged me to listen and learn from him, and work hard, and I would be successful. He taught me that I could work with my hands and make a good living.”

Hankins is humbled by the praise.

“Outside of my family, there is nothing in my life I am prouder of than seeing my former students working in a trade I taught them, supporting their families, and earning the money I told them they could,” he said.

“Teaching was the best job I ever had — not the most lucrative, but the most rewarding.”

Hankins’ impact on Y-12’s mission as a weld inspector is multiplied through the work of his former students, who he is proud to now call coworkers.

Duty. Honor. Country. It is a theme in David Turner’s life. From achieving Eagle Scout status as a young man to a 35-year military career concluding as a highly decorated retired brigadier general, Turner’s goals often derive from his desire to lead and serve.

“I feel as if I’m repeating that pattern in the work I’m now doing,” said Turner, who recently assumed the job of Vice President of Operations Support. “The mission we do for our country is so critical. It’s an honor for me to be a part of it.”

But Turner readily admits that he was not always the mastermind of his own destiny. Charting the course of his life has often involved the advice of mentors and teachers who saw something in him that he did not.

“You want to align yourself with people who have an interest in you,” he said. “They can see things in you that you may not and help you maximize whatever that may be.”

Who influenced you most in your life?

My grandmother was, without a doubt, a huge influence in my life. She was my Yoda. She was incredibly knowledgeable about so many things in life. I also had two mentors in my military career that were instrumental in guiding me. They still are involved in my life, and I continue to value their input.

What advice would you give to young people who don’t know exactly what they want to do?

Be open to advice and suggestion. I didn’t even know what an Eagle Scout was, but my best friend’s mother told me I would be one. I went home and looked it up, and I decided that I actually would become an Eagle Scout. I not only made Eagle Scout, but I held every possible leadership level in the Boy Scouts. I have never regretted listening to that suggestion. I also believe the Science, Technical, Engineering, and Mathematical (STEM) programs offer so many ways to learn about potential futures