Y-12 Blog

Learn something new about Bill Tindal, CNS’s chief operating officer.

Take 5 minutes and learn more about Bill Tindal, CNS’s chief operating officer.

When Bill Tindal joined Y-12 in 1995, being the chief operating officer for the management and operating contractor that now manages two sites and has about 10,000 employees didn’t even cross his mind.

“There are many times I thought I had reached the pinnacle of my career,” Tindal said. “When I look back on my roles, I would have been happy with several of those being my top stop — being the production manager of Building 9212 or being the vice president of production.”

During his 25 years, he’s grown along the way and keeps those lessons learned close at hand. “I think with each role I’ve had, I understand a little more that we all have important work to do. In my early days, I always thought the most important work being done on site was what I was doing, but then as I learned about the amazing work being done in other areas and organizations, I began to see how each role contributes a piece to the puzzle. I realized I was playing a small role in a much bigger picture.”

This sentiment — that every one of us has a role that contributes to the national security mission — is something Tindal has always been vocal about and something he wants everyone to appreciate.

“Through my experience, I have learned there are no unimportant jobs at either site. They are all important,” he said. “If one doesn’t work properly, it affects another group, which affects another, and so on. Pantex and Y-12 are part of an even larger whole, and we all have to do our part for the Nuclear Security Enterprise to be successful.”

Tindal said we often feel as if our piece is the most important part, but without all sites within the NSE working together, we wouldn’t accomplish the National Nuclear Security Administration’s goals.

“Asking for help and recognizing I don’t have all the answers is important,” Tindal said. “There are a lot of great people at Pantex and Y-12. Be humble, and ask for help when you don’t understand. If you really care about mission success, you have to stop and make sure you understand what people mean, especially when going into a new position.”

As COO, Tindal now travels to Pantex and has learned (and continues to learn) more about its missions and people.

“One thing that is different is each site’s lingo, but I’m improving,” he said. “One constant at both sites is the quality of the people. All are passionate and willing to help. Pantexans have the same passion and interaction that Y-12 employees have. I’ve always felt at home at either site.”

What advice would you give to your 1995, new hire, self?

What may feel like an immense challenge is really an opportunity to gain experience. Challenges (readiness reviews, frustrations with equipment) may be frustrating, but recognize that doing the right thing is rarely the easiest path.

What advice would you offer to someone who is starting their career?

Don’t be afraid to ask why. Ask why and how your job fits into mission success.

Don’t be afraid to fail. Each bad day turns out to be something we learn from. In my office, I have a bookshelf where I have mementos that remind me of lessons learned from risks or challenges we’ve faced. One of those items is a piece of quartz glass that was part of the first microwave project. We learned several things during that project, and the trinkets on my shelf remind me of the good and bad days.

What’s your top bucket list item and why?

When I retire and COVID is behind us, my wife and I want to complete the Great Loop. We hope to take a year to complete the 6,000-mile continuous boat route of connected waterways that allow you to boat completely around the eastern United States, starting in Tennessee.

With technology essential to our daily lives, cybersecurity education is increasingly growing

From cracking textbooks open to cracking codes, cybersecurity is entering the halls of secondary education in East Tennessee. In expanding cybersecurity knowledge beyond the sites, CNS Chief Information Security Officer Paul Beckman virtually met with 25 students from Bearden High School’s Cybersecurity 1 class, led by Timothy Cathcart, Ph.D., to present his professional insight in the digital world.

With more than 20 years in the industry, Beckman shared his background, life lessons, and experience with the class. Beginning his civil service career with the U.S. Department of Homeland Security in 2005, Beckman joined CNS in March and emphasized the gravity of ensuring cybersecurity for the CNS mission and the importance of cybersecurity in industries nationwide.

“What was traditionally considered just internet security has now become everything security,” Beckman said. “Whether it’s our phones, refrigerators, or vehicles, everything is becoming a computer, which increases our exposure to cyber risk; thus, the need to implement effective cybersecurity protections is no longer reserved to just our desktops.”

Beckman shared how his background and degree in psychology have translated to the cybersecurity industry - especially when it comes to assessing risk probability.

“Whether we realize it or not, it’s in our nature as human beings to continuously assess risk hundreds of times a day, and often times we get it wrong due to shortcuts our brains take called heuristics,” Beckman said. “From a psychology standpoint for example, we typically assess risks as being lower when they are within our direct control. These are the everyday risks like driving a car. Conversely, we tend to assess risks as being higher for things that we feel are out of our control, such as flying or riding as a passenger in a car. With cyber risks, we have to be cognizant of these inaccurate shortcuts our brains take and ensure we accurately and objectively assess the risks posed against our assets,” he said.

Meanwhile, as we continue to exponentially evolve in the digital era, Beckman recognized what it means for future growth and challenges in the cyber industry. In reference to Moore’s Law, which suggests that the speed and capability of our computers will double every two years with decreased costs, underscores the growing threat and signifies the importance of having cybersecurity professionals and skills to serve the demand.

“There is still by far a negative unemployment ratio in the cybersecurity industry. There are more cybersecurity jobs out there than there are people to fill them,” Beckman said.

Setting the stage to meet that need, Cathcart’s students are learning the basic concepts of cybersecurity with an emphasis on integration, application, practices, devices, and ethics. In addition to concepts, students are able to demonstrate how to implement cybersecurity features within a networking system and how to protect network information.

To those potential future minds of the cybersecurity industry, Beckman noted the importance of being fluent in cyber and overall information technology principles. However, when asked what he looks for in a future cyber professional or candidate, it’s having a learning mindset that thinks of ways to find solutions.

“We have the responsibility to encourage and inspire our youth to pursue the industry and become the next generation of information security professionals,” Beckman said. “No two days are the same in cybersecurity, and our adversaries are always adapting their tactics to our defenses, requiring that we have the strongest and brightest workforce to help defend against those adversaries.”

Beckman’s time with the Bearden students is just one example of how CNS is working to connect with young people who could eventually be part of the workforce. “The ability to make an impact and support the development of future professionals by pairing our experts with opportunities to share their knowledge is critical to our education community,” said CNS Education Outreach Specialist Kristin Waldschlager.

Executive director of Compassion Counseling Lakshmie Napagoda interacts with a client.

In days when we could all use a little compassion, Compassion Counseling in Maryville has been working diligently to help those with mental illness break the cycles of abuse and incarceration and retain employment.

With closures, quarantines, and economic uncertainty, the COVID-19 pandemic has made most of us feel a little frayed around the edges. For individuals with mental illness, that level of stress can easily reach the breaking point.

According to Lakshmie Napagoda, RGS, LCSW, executive director of Compassion Counseling, many families are caught in a vicious cycle of abuse, incarceration, and unemployment. She said, “Those who are able to find employment after incarceration often work in stressful settings. As a result, life stressors continue to add up.”

Grant vital during shutdown

Compassion Counseling received a grant from Consolidated Nuclear Security’s Community Investment Fund to provide clinical and educational services to those stuck in the cycle of abuse and incarceration. Unfortunately, those plans had to be modified because of the pandemic.

“Having the grant was especially helpful during the pandemic when our fundraising options were limited,” noted Napagoda. The challenge became delivering the counseling from a distance.

The program switched to telehealth, which was not without problems. Many of the Blount and Sevier County clients were not keen on the virtual sessions, and confidentiality concerns and slow internet speeds further exacerbated the problem.

Delivering counseling post-shutdown

Compassion Counseling’s program is driven by referrals from various sources, including the Blount Justice Center and the Blount County Probation Office. “As soon as the shutdown lifted, we received multiple calls from people arrested for domestic assault and those needing stress and anger management classes” said Napagoda.

With the influx of referrals, they still had to work with the social distancing restrictions, and their space wasn’t large enough. Fortunately, they were able to use a larger space in the building where they are located. By providing two sessions, they were able to accommodate 25 clients. Through the Community Investment Fund grant, they have been able to counsel 53 clients through group therapy and anger management sessions.

From resentment to acceptance

Court-ordered therapy often comes with resistance. According to Napagoda, acknowledging that resistance is the first step. The goal is for them to acknowledge that they played a role in their situation, realize that they need to make better choices, and hopefully develop some resilience to break the cycle.

“Anger seems give some people a sense of power,” noted Napagoda. “We try to explore causes of that anger to help people develop new behaviors.”

It’s hard work - for the therapists and the clients - but there are rewards. Suicidal clients finding a silver lining, a client finding a job after being fired for accosting a customer, and another developing an emotional connection that he’d never had before are just some of the examples of the real differences counseling can make on lives. Those are the outcomes in which Compassion Counseling is investing.

Visit Compassion Counseling’s website for more information about their services.

Demolition of Building 9720 22 at Y 12

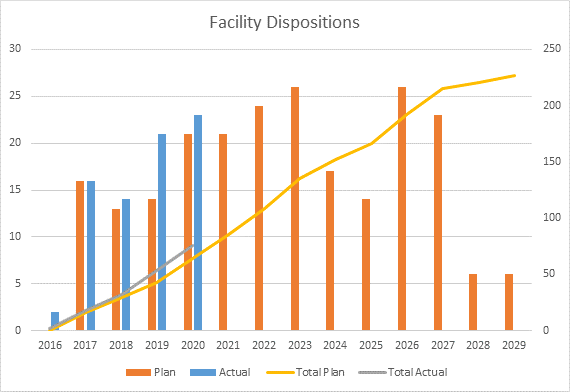

More than ever before, the landscape of Pantex and Y-12 is changing. In FY 2020 alone, 46 infrastructure projects were completed, and an impressive 21 facilities (11 at Pantex and 10 at Y-12) were demolished.

Diane McDaniel, senior director for Excess Facilities Disposition, has challenged the disposition team with a stretch goal to achieve 100 total demolitions within the years of FY 2015 and FY 2021.

“The disposition team is made up of approximately 50 individual contributors representing all organizations at Y-12 and Pantex. These team members, along with an outstanding subcontractor community and the NNSA Production Office, are the key to the program’s success. Because of their dedication and focus, the CNS disposition program is held up as the example for the other NNSA sites across the country,” McDaniel said.

CNS teams worked diligently to meet their FY 2020 goals during the COVID-019 mission critical operations so that they would be ready to hit the ground running to accomplish as much as possible within the safety envelope when they returned to the site.

“We have never attempted, much less achieved, that many dispositions and square footage of almost 30,000 square feet this year at Pantex,” said Pantex Excess Facility Disposition Program Manager Jennifer Simms. “We continue to achieve more facilities and square feet every single year. We are really ramping up and changing the landscape of the site one demo at a time.”

“Demolitions are important to reduce the site footprint and eliminate facilities that present significant hazards. We have to remove the old to make way for new mission essential facilities,” said Y-12 Excess Facility Disposition Program Manager Kevin Bradford.

“Because we are reducing the footprint with demos, it gives us the opportunity to work with NNSA to obtain the funding needed for new facilities,” said Laura Fox, Pantex Projects Management. “These new facilities will provide greatly improved working conditions for our personnel, as well as provide greater reliability of facility systems.”

Planning for demolition starts no less than two years before the building is actually torn down. Many times, characterization of hazards within and around the facility, location and condition of utilities, and other factors must be known ahead of even starting the drawings that must be produced and provided to contractors for bid.

“Taking down old facilities is always challenging,” Fox said. “Many times, the drawings from when these facilities were constructed are either not available or are unreliable.”

She said it is truly a team effort between organizations including Projects, Procurement, Engineering, Construction Management, and the contractor who work hand in hand to overcome issues and get these buildings down.

New behind the scenes challenges for FY 2021 demolitions are already being reviewed for another 21 planned demolitions next year and more than 25 in FY 2023.

Heroes don’t always wear capes (but they do wear face coverings). These three Y-12ers jumped into action to help a Kentucky man suffering from dementia. (from left: Chris Griffis, Mark Butcher, and Jack Bolinger)

Most Y-12 employees try to be helpful. Last month, three Y-12ers proved that statement when they were in the right place at the right time.

Chris Griffis, Jack Bolinger, and Mark Butcher were driving near the Horizon Center on Highway 58/95 when they spotted someone in the road.

“He looked to be in distress, and we stopped to see if he needed help,” Griffis said.

The three got out of the car and asked the man if he needed assistance. The man was confused, couldn’t answer any questions, and had a wound on his head.

Bolinger said, “The more we talked to him, the more it was apparent that, at the least, he had a concussion. He couldn’t tell us who he was, where he was headed, or where he came from. He thought he was in Kentucky. He was barely making coherent sentences.”

Bolinger called 911, and the three stayed with the man until the paramedics arrived.

“Everyone is always in a hurry, and I get that, but take time to figure out someone’s situation,” Butcher said. “You should always look to lend a helping hand, especially when you can improve or help someone else’s situation.”

The paramedics took him to the hospital for evaluation. Later that day, Bolinger received a call from one of the paramedics that the man was suffering with dementia and had been missing from Kentucky.

Griffis said, “Sometimes the world we live in seems quite dark; however, there are many more good people in the world than people who would wish to do you harm. You absolutely need to be aware of your surroundings for the safety of you and your loved ones. Conversely, there are people everywhere who could use some assistance in one form or another. You never know how much a seemingly small gesture can mean to someone who needs it.”

“Something that is often missing from people’s actions are doing them from a service perspective, where nothing is in it for them,” Bolinger said. “If you see a need, take action! Never underestimate the impact you can have in someone’s life by a seemingly insignificant action.”

These good guys advise to look for places where you can help. Griffis said, “It’s vital in our country right now to help those who truly need it.”

It pays to be alert, and when you see something — even someone in distress — say something. Thanks to these three Y-12ers, the missing Kentuckian was soon home.