Y-12 Blog

Congratulations to Kevin Shipp of Y-12 Engineering; he was awarded the 2020 Sandia National Laboratories Weapon Intern Program Leadership Award. He is a graduate of the 2020 program, which was the 25th class.

This award recognizes individuals who demonstrate exceptional leadership in all facets of the program, including academic performance, project leadership and team management performance, professional development, and peer assessment.

“The Sandia National Laboratories Weapon Intern Program was an incredible experience,” Shipp said. “We were given access to resources and a wealth of knowledge that are unparalleled in the Nuclear Security Enterprise. It was also a privilege to participate in the program with my classmates who are top notch people from around the NSE and DOD. So, I was humbled and honored to be selected for the leadership award by them.”

Shipp also was chosen to speak at the WIP graduation ceremony on behalf on the class. He has made exceptional impressions on his peers as well as the WIP staff, bringing great credit upon himself, CNS, and the NSE.

Joshua Schwartz (left), Chris Haught (center), and Dallas Moser discuss maintaining strict controls to ensure nuclear criticality safety.

Anyone who works around special nuclear material at Pantex or Y-12 is aware of the enormous energy release possible from these materials. There are few things certain in life, but for CNS, maintaining strict controls on nuclear criticality safety is one. While the material forms at Y-12 present greater risks, both plants deal with quantities of nuclear material sufficient to warrant consideration for prevention of an inadvertent criticality.

“Y-12 suffered a criticality accident in the late 50s. As a result, many of today’s Y-12 and industry standard NCS program elements grew from lessons learned from that event,” said Ken Keith, deputy vice president of Mission Engineering. “We never, ever want to even approach a repeat event.”

Nuclear Criticality Safety is a collection of programs and activities that help ensure we do not repeat that event, and it requires constant vigilance. An inadvertent or uncontrolled release of energy in the form of radiation and heat is a criticality. To give you a sense of the hazard, only 700 g of 235U has the potential for criticality under the right conditions.

“The unique properties of uranium can create the energy to power reactors and weapons,” said Gary Sanders, CNS vice president of Mission Engineering. “But it requires special controls to both shield our workers from the radiation effects and prevent a cascading reaction.”

Chief NCS Engineer Chris Haught added, “The challenge we face with this hazard is when conditions are unsafe and approaching very near to a critical configuration, there are no warning signs. Because of this, the criticality hazard is non-intuitive and presents unique challenges for ensuring personnel safety. We understand fire hazards, or hazards around pressurized fluids or electricity through normal life experiences, but the criticality hazard must be learned through training and actual operating experience.”

That experience has led to constant monitoring, adjustment, and improvement.

Unanticipated changes in processing activities at CNS over the past couple of years challenged engineers and operations staff to better understand the processes, the assumptions for actions and material flow, and the why of why we care about what we do. CNS has reviewed the way it does business from top to bottom.

“We’ve improved several review and oversight functions, hired additional staff in several areas, improved lines of responsibility, improved training of operations staff, and improved administrative processes,” Keith said.

“We have further strengthened our Nuclear Criticality Safety Program with a dedicated leadership position and integrated and resourced a plan to address the legacy issues to ensure safety of operations,” said Sanders.

That dedicated leadership position is filled by Susan Kozemko, senior director of Criticality Safety Management & Integration. She manages a multidiscipline team that implements criticality safety requirements in a formal and disciplined manner. She also serves as chair of the Nuclear Criticality Safety Committee that is accountable to the site managers and provides oversight and guidance for the NCS program at Pantex, Y-12, and the Uranium Processing Facility.

“Vigilance is required in everything I do to ensure errors are corrected in a timely manner, actions are taken to prevent recurrence, NCS requirements are met, and improvements are proactively evaluated,” Kozemko said.

The work of NCS engineers is never over; it is a constant environment of review, adjust, and improve.

Keith summarized, “While many improvement efforts continue, much has been accomplished and more is to be done.”

Take 5 minutes and learn more about Melissa Blair, CNS's new senior director of Enterprise Strategic Planning. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

In addition to being the senior director for Security Programs, Melissa Blair has taken on a new role as the new senior director of Enterprise Strategic Planning. She is responsible for leading a complex, multiyear site planning process, documenting milestones, and ensuring the process is communicated and working.

It’s not what she thought she’d be doing when she entered college as an education major.

“I always wanted to be an elementary school teacher,” she said with a slight smile. “I quickly learned that I lacked the creativity to come up with construction paper and sticker activities for kids and switched to learning how to train adults in business and industry.”

And that’s what she’s been doing for 30 years. In the process, she’s gained a diverse set of experiences across DOE’s weapons complex, which has prepared her well for her current role.

What is your favorite aspect about your work environment? How does that aspect make you know the mission is being met?

When I see someone working with a sense of urgency. Their dedication to meet the mission and our deliverables despite all the challenges is inspiring.

What CNS principle drives you to be successful?

There are really two: Promote a Questioning Attitude and Continuous Improvement. Anyone who has worked with me knows I ask lots of questions and encourage others to as well. Particularly, “why do we do it that way,” and “is there a better way?” I’m always looking for the lessons learned in a situation and to improve upon the process.

What top strength do you bring to your organization and why?

My energy and ability to work with and inspire others to work with a sense of urgency. If you see me on a Thursday morning, watch out … that’s when I come to work with my half caffeine coffee and really kick it into high gear!

Are you doing what you envisioned as a young adult? If so, describe how you got here.

Kind of … I always wanted to be an elementary school teacher and started out as an education major in college. In 1990, I started with the company in Paducah as an instructional designer when all five Martin Marietta sites were under one contract. I also taught basic instructor training, which I really loved, as it’s just as important to know how to design instruction as it is to understand how to teach adults. I transferred to ORNL, then to Y-12, and stayed with training until BWXT took over the Y-12 contract. Process improvement was part of the contract, and the first Six Sigma group was formed, so I left Training in 2001 to become a certified Six Sigma Black Belt. I spent the next 11 years in Projects before landing in Program Integration in 2016.

What one thing would your coworkers be surprised to know about you?

Before I met and married Jim, I was pretty much a homebody. He’s shown me that that I don’t have to be perfect to enjoy sports and the outdoors. So, now I am a certified SCUBA diver, have my motorcycle license, have taken up golf, and have become a big time foodie. We’re always looking for new items to cook together.

What work advice would you offer someone who is new to Pantex or Y-12?

You don’t need a technical degree to be successful in this company. I have an associate’s degree in word processing (I can type really fast!); B.S. and M.S. degrees in education, training, and development; and a doctor of education in educational psychology, specializing in collaborative learning — all non-technical degrees. Every position I’ve held over the last 30 years has put me with a team where I am not the expert (except for training). Being successful is about who you work with and understanding and playing on each other’s strengths to collaborate and make the best decisions.

Y-12 air condition and refrigeration mechanics, from left, stand beside the crimping tool (on top of an air conditioning unit) that allows the team to work more safely and efficiently.

Where do the best ideas come from? At Y-12, they often spring from the “voice from the floor,” from those who are closest to the work.

The site’s air condition and refrigeration mechanics recently came up with a safer, more efficient way for routinely applying a fitting to a copper pipe, a task the AC&R crew often perform when installing, repairing, and maintaining refrigerant lines and humidity control systems.

The usual method for fusing the metal includes a brazing torch, which involves lots of paperwork and preplanning (analysis of job hazards, a “hot work” permit, a fire watch on standby) and donning sometimes bulky personal protective joining equipment (fire retardant clothing, leather gloves).

“We have to sand and prep the fitting and pipe, make sure all flammable and combustible materials are at a safe distance, and have our fire extinguisher and fire watch person with us,” explained mechanic A. Chittum. “We use a light torch to heat up the area we are brazing and braze the fitting on the pipe and then let it cool. For just one fitting, this task can take about five minutes, depending on pipe size and location.”

Chittum and the rest of the AC&R crew knew of a better way to accomplish most fusing jobs: a flame-free, off-the-shelf crimping tool to create a seal. Though not suitable for every application at the site, the tool can be used in areas where it can be difficult to obtain a burn permit (such as the Destruction and Recycle Facility with its high paper content and dust) or where a burn permit cannot be issued (storage areas with highly flammable materials).

“Using the tool, it takes eight seconds to crimp the fitting on the pipe with no cool down period and with a lot less preplanning and PPE and fewer hazards,” said mechanic M. Carter.

The crew presented their idea to Infrastructure’s Proactive Safety Team, led by Scott Underwood, senior director of Y-12 Infrastructure. The team, which aims to prevent injuries before they occur, reviewed and readily approved the mechanics’ idea. Within two months, the crew were using the new tool.

“Our management supported our idea from the very beginning,” said mechanic M. Owens. “We all felt that this device would enhance our ability to perform our work and provide better protection. Technology is always changing. The more we introduce it to our everyday tasks, the more efficient and safer we become.”

B. Williams, section manager of Balance of Plant maintenance work activities, said he was proud of the AC&R crew for applying the latest technology to their work.

“This technology saves time, money, and makes Y-12 safer for both the crew and the facilities where they are working,” Williams said. “The crew’s effort displays the serious approach Infrastructure is taking to better support our on site customers and Y-12’s mission.”

Infrastructure’s Linda Fiore, team lead for the Proactive Safety Team, echoed Williams’ sentiments.

“We can always reply on the vast experience, knowledge, and skill sets of our bargaining unit employees to come up with ideas and best practices to help create a safer, more productive work environment.”

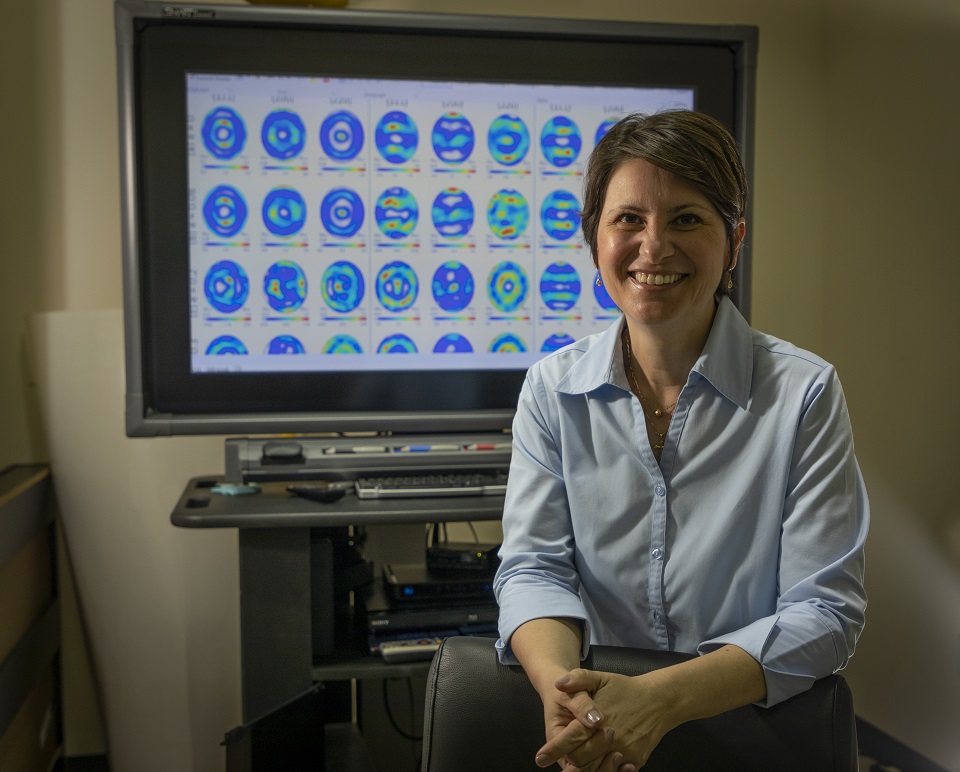

Elena Garlea’s work was recently published in Journal of Material Science and Engineering: AM as part of a larger effort carried out in collaboration with other NNSA sites and the University of Tennessee.

Everyone wants to work in a field that keeps them engaged and on the cutting edge. Elena Garlea of Y-12 Development is one such person.

“My field of material characterization is very exciting,” Garlea said. “There is a great appreciation for new technologies at Y-12, which allows me to do cutting edge, fundamental research.”

In her research, she’s found one important aspect for metal additive manufacturing technology is the porosity that develops in the part during fabrication. That porosity can have a significant effect on its performance. She’s led research projects to advance understanding of the AM technology with the focus on porosity.

“During 2019, I published four journal articles; two of which were on AM. This month, a third article was published on this AM series,” she said.

Her latest paper, “Influence of defect characteristics on tensile deformation of an additively manufactured stainless steel: Evolutions of texture and intergranular strain,” can be read online.

“The article reports on the type of pores and their role on deformation to failure of test samples. The AM metal, likewise the conventional metal, is made out of grains (microscopic crystals) that have a certain orientation due to processing conditions,” Garlea said.

Grain orientation is the most important characteristic that defines the strength of a material. The novelty of this work was to use a special load frame equipment purchased by Y-12 Plant Directed Research and Development, and the team went to the Advanced Photon Source at the Argonne National Laboratory for the experiments.

“This facility provides high energy, high resolution synchrotron X-ray beam to monitor grain orientation and porosity at the time the deformation takes place (in situ),” she explained. “This effort was coupled with results obtained using other specialized technologies, like Resonant Ultrasound Spectroscopy, available in Development.”

Garlea said this research allows for the understanding of how processing conditions influence the orientation of these grains and the level of porosity that can become detrimental.

“This project was part of a larger effort carried out in collaboration with other NNSA sites and the University of Tennessee. Funding was provided by PDRD and NA-123 programs. This type of study helps advance the understanding of the technology that can be transferred to fabrication of other materials.”