Y-12 Blog

Building 9111 during demolition.

Building 9111 during demolition.

Four Y-12 project teams were recognized as fiscal year 2017 NA 50 Excellence Award winners. The projects included demolition of Buildings 9111/9112 and 9616-10, Energy Savings Performance Contract lighting upgrades, Building 9204-2 (Beta-2) Annex demolition, and Building 9201-05 (Alpha-5) Annex encapsulation. A fifth award was given to a joint Y-12/Pantex team for Construction Work Processes Improvements.

Jim McConnell, National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations, said, “NA-50 Excellence Award winners are recognized for outstanding accomplishments involving innovation, effectiveness, teamwork, overcoming adversity, and enabling future success. Your work in revitalizing our infrastructure will help support our missions for years to come.”

Demolition of Buildings 9111/9112 and 9616-10

Demolition work typically requires significant coordination between state and federal regulators, but the team that demoed three Y-12 buildings was able to gain regulatory approval in about 50 percent of the normal cycle times.

Kevin Lancaster, the team lead, said, “Through extraordinary teamwork, collaboration, and anticipating potential barriers, the team was able to complete the entire demolition in approximately 60 percent of the original baseline schedule and at about 75 percent of the baseline cost. We estimate the team’s actions saved approximately $1 million.”

Demolitions like these reduce overall risk for Y-12 and DOE/NNSA through eliminating the costs of managing these buildings and the associated worker safety issues they present.

Members of the team who demolished Buildings 9111, 9112, and 9616-10 receive an Award of Excellence from Jim McConnell.

Members of the team who demolished Buildings 9111, 9112, and 9616-10 receive an Award of Excellence from Jim McConnell.

Y-12 Energy Savings Performance Contract lighting upgrades

Since FY 2016, Y-12 has used energy savings performance contracts to enhance building infrastructure, including an fiscal year 2016 project to modernize 11,450 lighting fixtures in 123 facilities, currently managed by Johnson Controls Government Services. The upgrades improved lighting conditions, reduced electricity use by 36 billion Btu per year, and saved more than $538,000 annually in energy costs.

The lighting upgrades were completed to allow for minimal disruption of production and operational mission critical priorities.

“We held regular team meetings and had good communications,” team lead Anna Beard said. “An innovative lockout/tagout procedure allowed the team to perform the work safely while saving time, effort, and money.”

The team also received the Secretary of Energy’s 2017 Federal Energy and Water Management Award for work completed by NPO, CNS, and Johnson Controls, Inc. It was the only group from DOE to receive this award in 2017.

Members of the team that performed lighting upgrades for the Energy Savings Performance Contract receive an award from Jim McConnell, National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations.

Members of the team that performed lighting upgrades for the Energy Savings Performance Contract receive an award from Jim McConnell, National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations.

Y-12 Building 9204-2 Annex demolition

The mission work that Y-12 employees perform requires specialized equipment like Kathabar systems. These systems are needed in areas of Building 9204-2 to maintain critical temperature and humidity requirements.

Cliff Hastings, team lead, said, “We found the penthouse structure floor slab was severely degraded. So the best plan to access the floor slab for necessary repairs was to demolish the 9204-2 Annex, a concrete block building located beneath the penthouse, since the condition of the slab was expected to continue to deteriorate.”

The team completed demolition by using innovative barrier configurations to protect close, surrounding infrastructure.

“Our team worked together to ensure that numerous legacy systems were fully vetted without incident while we performed the isolation process,” Hastings said.

The project resulted in a cleared and usable surface that provides the most efficient and cost- effective means to access the underside of the penthouse. Access is allowing for much-needed inspections and repairs of the penthouse structure as required to maintain continued safe operation of mission-critical Kathabar systems.

Shown are many of the team members who successfully completed demoing the Building 9204 2 Annex.

Shown are many of the team members who successfully completed demoing the Building 9204 2 Annex.

Building 9201-05 (Alpha 5) Annex encapsulation

Creativity and innovation are two characteristics often needed when working on a team, and the Building 9201 05 Annex encapsulation team demonstrated a unique approach in handling multiple issues. They created a single cost effective solution that also reduced the risk from radiological contamination and environmental insult inside.

“The benefits of this innovative approach reduced risks associated with the facility and the co located workers,” team lead Kevin Lancaster said. “Further benefits include allowing the project a broader range of demolition strategies enabling and enhancing future project success.”

Jim McConnell, National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations (far right), presents an NA-50 Award of Excellence for Alpha-5 Annex Encapsulation.

Jim McConnell, National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations (far right), presents an NA-50 Award of Excellence for Alpha-5 Annex Encapsulation.

National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations Jim McConnell (second from right) presents an Award of Excellence for Construction Work Processes Improvements.

National Nuclear Security Administration’s Associate Administrator for Safety, Infrastructure and Operations Jim McConnell (second from right) presents an Award of Excellence for Construction Work Processes Improvements.

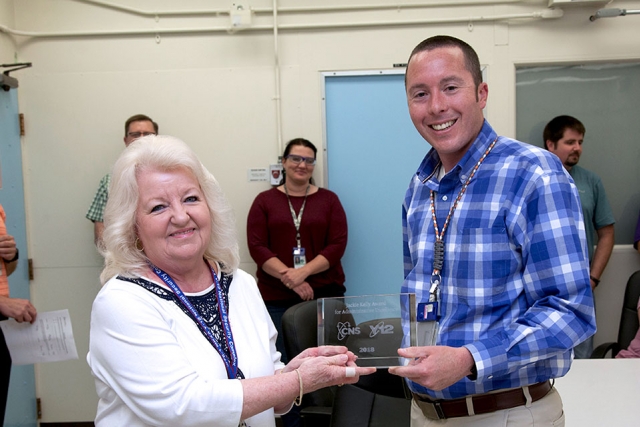

Sue Lankford, administrative assistant for Analytical Chemistry, accepts the Jackie Kelly Award for Administrative Excellence from Rob Kring.

Sue Lankford, administrative assistant for Analytical Chemistry, accepts the Jackie Kelly Award for Administrative Excellence from Rob Kring.

“We all know her voice. We all know her smile. We all know her helpful ways.” This was the opening line from one of two submissions nominating Sue Lankford, winner of the 2018 Jackie Kelly Award for Administrative Excellence.

In total, 23 administrative assistants from Pantex and Y-12 were nominated, and a five-person committee was tasked with ranking each nomination after all names had been removed. The nominees were evaluated on performance in five categories: dedication, conscientiousness, caring, can‑do attitude, and capability.

The Jackie Kelly Award began in 2017 as a way to appreciate and recognize administrative assistants. It also provides managers and supervisors with an opportunity to pause and appreciate the administrative assistants in their area. Pantex employees participated this year, and there were twice as many entries as last year. Quality’s Kevin Corbett, who championed this recognition in honor of Jackie Kelly, his former assistant, said the quality of the nominations substantially improved from last year.

Lankford was recognized as the 2018 recipient at a surprise luncheon in her honor in Building 9995. Rob Kring, one of Lankford’s nominators, said, “In her almost 35 years of service at Y‑12, Sue has worked tirelessly every day to ensure our jobs are easier and there are smiles on our faces. She possesses all the attributes that this honor aims to recognize.”

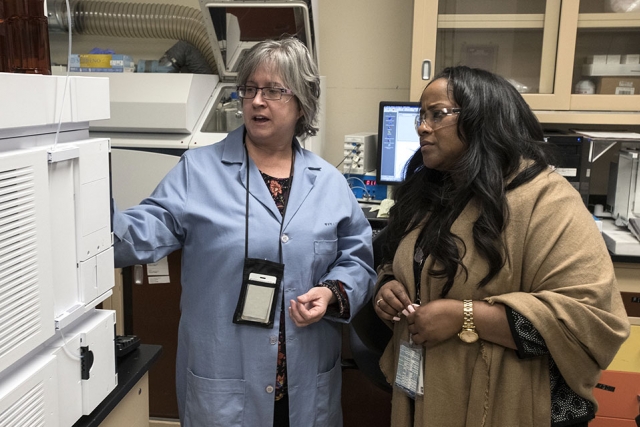

Stephanie Steelman (left) shows Nicole Nelson-Jean, NNSA Governance Committee chair and Savannah River Site manager equipment at the Pantex chemistry lab.

Stephanie Steelman (left) shows Nicole Nelson-Jean, NNSA Governance Committee chair and Savannah River Site manager equipment at the Pantex chemistry lab.

In April 2018, an independent team conducted a peer review of the NNSA Production Office, Pantex and Y-12. The peer review is a recently established process by NNSA designed to leverage the experience of leaders from across the enterprise (NNSA headquarters, field offices, management and operating partners, and corporate parents) to identify and share lessons learned and best practices to strengthen the governance process throughout NNSA.

Ted Sherry, Performance Excellence manager, said, “While the team was at each site, the team evaluated our governance processes, policies, and effectiveness. They were reviewing the roles of the contractor, the parent corporations, the federal field office, and NNSA headquarters.”

Prior to their visit, the team received detailed documentation packages about the policies, procedures, and processes for governance.

“The peer review team received briefings, participated in field observations of governance processes, and had open dialogue with employees,” Sherry said. “The preliminary out brief indicated that our governance model is working well and is effective. The team gave us suggestions in several areas for improvements, as well as suggestions to improve the peer review process itself.”

The peer review team is drafting the final report.

Two tower cranes were installed early this year as part of the construction of UPF. The cranes, which are 300 and 360 feet tall, will be used to move materials and equipment during construction. Having high-capacity, stationary cranes within the footprint of the buildings gives UPF the ability to reach every spot in the construction zone. Using the cranes is more efficient and safer than moving materials manually. The cranes have been used to move rebar for the foundation of the Mechanical Electrical Building.

In honor of Earth Day, Y-12 displayed several sustainability booths in the Jack Case Center gallery April 19. Various on-site organizations, including the Uranium Processing Facility, Sustainability and Stewardship, Development, and the Energy Program, shared how they reduce and reuse. External organizations including the @national park service, @knoxsmarttrips, and @TennesseeWildlifeResourcesAgency also shared tips with employees. At the LiveWise booth, employees could donate used (and not abused) athletic shoes and eyeglasses.

The Aluminum Beverage Can Committee also selected four charities that will receive a $200 donation from proceeds made from recycling employees’ ABCs. The organizations selected are Free Medical Clinic in Oak Ridge, Koinonia Foundation of Tennessee, Remote Area Medical, and the Restoration House of East Tennessee.