Y-12 Blog

The first nuclear process equipment is installed at the Uranium Process Facility Salvage and Accountability Building.

The first nuclear process equipment is installed at the Uranium Process Facility Salvage and Accountability Building.

The Uranium Processing Facility (UPF) Project installed the first nuclear process equipment, a process skid, at the Salvage and Accountability Building (SAB) in September. It is one of approximately 200 skids that will be installed at UPF.

A skid is a grouping of preassembled components, like tanks, valves, and pipe spools. Each skid is a “building block” for the overall process system. The SAB is essentially a small chemical processing plant. The skid is a preassembled and tested portion of that plant.

“This marks a major step in our commitment to build UPF by 2025,” said UPF Vice President and Project Director John Howanitz. “We’re not just constructing buildings anymore; we’re starting to accept and install process systems that will eventually support production operations. As buildings go vertical and walls go up, construction will be punctuated by installation of larger equipment. The placement of this first nuclear process skid is an illustration of our momentum.”

“This was a heavy, complicated lift that required precision placement,” said SAB Deputy Area Manager Randy Holman. “It required two cranes to lift the equipment into place before the crew bolted it to the second floor. The team came together and placed the skid without incident. The work and planning that went into setting this skid in place really paid off. The team deserves the credit for achieving this milestone.”

The UPF supports the Uranium Mission Strategy, which ensures the long-term viability, safety, and security of enriched uranium capabilities in the United States. UPF will replace casting, special oxide production, and salvage and accountability capabilities from a World War II era building with a modern, more efficient, and safer facility for conducting highly-enriched uranium processing operations at the Y-12 National Security Complex.

Consolidated Nuclear Security, LLC, is building UPF for the National Nuclear Security Administration through a subcontract with Bechtel National, Inc.

The first nuclear process equipment was delivered to the Uranium Process Facility (UPF). It is one of approximately 200 skids that will be installed at UPF.

The first nuclear process equipment was delivered to the Uranium Process Facility (UPF). It is one of approximately 200 skids that will be installed at UPF.

Y-12 intern Colleen Hyer inspects the sublimation chamber she and intern Dalton Parker designed.

Y-12 intern Colleen Hyer inspects the sublimation chamber she and intern Dalton Parker designed.

At the Y-12 National Security Complex, you won’t find employees lurking around in trench coats, but for intern Colleen Hyer, the site does hint of intrigue.

“Because of the tight security, it’s got a bit of a secret agency feel. Mysterious and exciting,” she said. “

Hyer, a junior majoring in chemical engineering at South Dakota School of Mines and Technology, might not have found much in the way of spy stuff at

“My project dealt with electroplating aluminum onto a zirconium substrate to see if zirconium is a good testing substitute for uranium,” she said. “The plating keeps certain components from corroding in the oxygen atmosphere.”

One of her tasks was to create an aluminum and stainless steel sublimation chamber, which is used to convert a solid to a gas. “There are glass ones out there, but the substance we worked with reacts violently with materials in glass, so we needed the chamber made from a combination of the two metals,” she said.

John Freiderich, Hyer’s work mentor, didn’t provide a blueprint for making the chamber. Instead, he wanted Hyer and intern Dalton Parker, a senior from Tennessee Tech, to put their problem-solving skills to work.

“I’ve had good success incorporating interns into my projects,” Freiderich said. “We work on tasks together, but at the same time, I wanted Colleen and Dalton to be free thinkers. I wanted them to build a chamber on their own, to learn and figure out the science and engineering they don’t know yet.”

They did just that, coming up with their own working prototype.

| Y-12 2019 interns by the numbers | |

|---|---|

| 29 | interns |

| 24 | undergrads |

| 5 | grad students |

| 19 | colleges and universities represented |

| 9 | majors represented |

| 10 | home states represented |

| 50 | Y-12 interns hired since 2015 |

Hyer and Parker were two of 29 interns at the site who worked on projects ranging from making ceramic radiation detectors to building a procurement website to designing the circuit for a probe to detect the liquid and conductivity of molten salt to developing an app for a machine indicator light.

The intern program supports the site’s National Nuclear Security Administration mission in two ways: (1) students, some of whom obtained security clearances for their internship, apply their knowledge and skills to projects that directly support mission work, and (2)

More than 50 interns have been hired as employees since 2015, said Amanda Muirhead, who coordinates the

“I think what I enjoy most about this job is seeing how the students grow during their time here,” Muirhead said. “Something I have been encouraged by is just how positive this year’s group has been and their eagerness to participate, learn, and be challenged.”

Hyer’s next challenge is finishing her degree. And then? “In five years, I could see myself working at

Y-12’s summer interns came from 10 states and represented more than 19 colleges and universities.

Y-12’s summer interns came from 10 states and represented more than 19 colleges and universities.

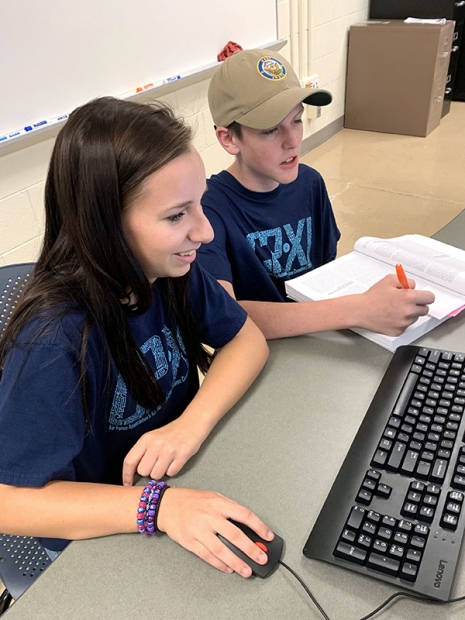

For generations of students, lunchtime has been a favorite part of the school day. For a group of students at Oak Ridge High School in Tennessee, however, the midday break took a back seat to cybersecurity sleuthing.

“I could sit for hours working puzzles, not stopping for anything, and a computer is just a big puzzle,” said Elizabeth, an ORHS junior and participant in a summer cybercamp sponsored, in part, by the Y-12 National Security Complex.

“I actually had to require students to leave their computers to eat lunch,” said Y-12’s Mike Hylton, who conducted the weeklong camp for 11 ORHS students.

Hylton, an instrumentation and controls design engineer in Y-12’s Cat 2 Design group, coached students in computer-based scenarios designed to teach fundamentals of computer networks, encryption, and cybersecurity. The Air Force Association’s Youth Cyber Education Program provided the curriculum materials.

“The program helps expose students to a basic awareness of how cybersecurity affects all of us in our everyday lives,” Hylton said. “It helps develop an interest in cybersecurity and other computer fields that are needed at Y-12 and in almost every government agency across the country.”

Campers worked in teams to find and correct vulnerabilities in operating systems of a fictitious company. They checked user passwords, files, software, and accounts for compliance with the company’s security policies and protected computers against viruses and hacking threats. The teams scored points for every vulnerability they corrected.

“I tried to make my computer as unhackable as possible,” said Elizabeth, who wants to become a cyberwarfare engineer for the Navy. “It was fun getting lost in the numbers behind what you see on the screen.”

Fellow camper Justin, a senior, said learning how computer systems work from the inside out makes him less vulnerable to being duped. “There are plenty of scams and cyberattacks out there,” he said. “The more you know, the better prepared you are.”

Hylton agreed. “It’s important to have basic knowledge of how our electronic information is transferred and shared, both intentionally and unintentionally,” he said. “We are at the point where it is almost impossible to function in a connected world without a great deal of information changing hands.”

Y-12 sponsors the camp as part of its educational outreach efforts to develop the science, technology, engineering, and math skills the site needs to fulfill its National Nuclear Security Administration mission.

Oak Ridge High School students Elizabeth and Thomas work together on a training scenario to secure a company’s operating system.

Oak Ridge High School students Elizabeth and Thomas work together on a training scenario to secure a company’s operating system. Pantex Honor Guard members Jeremy Baker (left), Chris Lewis (second from left), and Bobby Nash (far right) train the newly formed Y-12 Fire Department Honor Guard whose members include (starting third from left): Ben Norton, Doug Allen, Joe Herrell, Brandon Hitchcock, Lee Scofield, Jonathan Rood, Craig Shaver, Josh Bray and Bob Strunk.

Pantex Honor Guard members Jeremy Baker (left), Chris Lewis (second from left), and Bobby Nash (far right) train the newly formed Y-12 Fire Department Honor Guard whose members include (starting third from left): Ben Norton, Doug Allen, Joe Herrell, Brandon Hitchcock, Lee Scofield, Jonathan Rood, Craig Shaver, Josh Bray and Bob Strunk.

Members of the Pantex Honor Guard visited Y-12 in June to train their fellow firefighters.

“We received approval to form an honor guard, and we decided who better to train us than our fellow coworkers,” Assistant Chief Mari-Kaye Monday said. “Pantex’s Honor Guard was established in 2011.”

Three Pantex members conducted a week of training with the 10 members of the newly formed Y-12 Fire Department Honor Guard.

“We wanted to ensure we were ready to serve as a color guard or perform a variety of events, such as opening ceremonies, parades and funeral services for fallen fire and emergency services members,” she said.

Monday said their team has worked for years to establish an honor guard within the Y-12 Fire Department. “It is the mission of the fire service honor guard to exemplify honor, respect, and dignity while embracing fire service tradition. We’re continuing the pursuit of excellence by establishing the honor guard, and the Y-12 Fire Department is striving to exhibit pride, professionalism, and teamwork to represent CNS.”

Watch this video to learn more.

Members of the CNS W80-4 Life Extension Program recently received an NNSA Defense Programs Award of Excellence.

Members of the CNS W80-4 Life Extension Program recently received an NNSA Defense Programs Award of Excellence.

It’s a busy time in the modernization world at Pantex and Y-12 as employees continue working on the B61-12, W88 Alt 370 and W80-4. The W80-4 Life Extension Program (LEP), is a long-range standoff cruise missile that will be used by the U.S. Air Force in the bomber leg of the nuclear triad. Pantexans and Y-12ers are working to refurbish, reuse or replace the warheads’ nuclear and non-nuclear components to extend the service life of the warhead for an additional 30 years while improving its safety, effectiveness, and security.

This level of work has not been seen across the Nuclear Security Enterprise in more than 30 years and will require close coordination and integration with all involved to effectively and efficiently ensure all milestones and deliverables are met.

The Pantex team is working to produce, formulate, and qualify two new insensitive high explosive material streams for the LEP. To meet this challenge, they are working with Lawrence Livermore National Laboratory and Holston Army Ammunition Plant to develop and qualify new IHE material.

Working with older infrastructure and tooling is another challenge for both Pantex and Y-12. The legacy tooling was not designed to the tighter assembly, so that requires all of the tooling supporting operations on this program to be re-designed, prototyped and put in place.

At Y-12, they are appreciating a new approach the nuclear design agency has taken to meeting design requirements. Previously, Y-12 had to rely on reused and partially rebuilt components as there are significant challenges in making all new components. However, the design agency, Lawrence Livermore National Laboratory, is simplifying where possible, taking advantage of additional reuse opportunities, and working as a real partner to minimize burdens on existing Y-12 capabilities.

There have been challenges with this LEP, such as compressing the schedule by two years, but there have also been successes. Those successes earned the Pantex and Y-12 W80-4 teams an NNSA Defense Programs Award of Excellence.

Obviously, working on three LEPs at one time will present competing priorities and challenges for Pantex and Y-12. With teams like these, the sites are well positioned to be more efficient. It is imperative because the nation requires it.