Y-12 Blog

Take a few minutes and learn about CNS’s Mike Mulligan, Subcontract Management Program lead. All views and opinions are the employee’s own and do not necessarily reflect those of CNS.

A stint as a barista brewed changes in Mike Mulligan’s life, professionally and personally.

“I’ve always been kind of passionate about coffee,” said the CNS Subcontract Management Program lead, “and I really enjoyed the business aspect of the job. Also, there was this consulting side where I could help people find their best fit (when it came to coffee).”

“And it actually gave me my first taste of supply chain management (the handling of the production flow of a good or service — from the raw components to delivery of the final product to the consumer). It was a great job, but offered no real upward mobility. However, it turned out to be the place where I met my wife, Ashley.”

The place was Café Lemont in Lemont, Pennsylvania, not far from Penn State University, where he graduated with a B.S. degree in psychology in 2014. A few jobs and years later, he attended the Haslam College of Business at the University of Tennessee and earned his M.B.A. in supply chain management. This led to an Operations Support internship at Y 12 and his current position.

Since December 2020, Mulligan has coordinated with the subcontract technical representatives, who are the individuals authorized to oversee subcontractor work activities.

Are you doing what you envisioned as a young adult?

About a decade ago before becoming more career-minded, I saw myself as a musician or performing artist. I played with two bands in college, one cover and the other original, Desert Island Friend. After graduation, I chose to stick with the original band, moved out to California for a year of service with AmeriCorps, and we recorded an EP [extended play], “Jackson Street.” I composed the piano parts on all of those tracks. Even though my life has taken a different path, I still enjoy playing and composing as a hobby.

What CNS principle drives you to be successful?

Attention to detail. In the age of teleworking, it is critical we pay even more attention to our language, both written and spoken. People can read different inflections based on the language we use.

How does patriotism factor into your life? Did your level of patriotism change after working at Y-12?

My father was in the military, so patriotism was instilled in me at a young age. He always said, “Keep charging forward — even when things get tough.” I think it’s grown since I’ve been here. I see CNS making a positive impact on our country, like my father did, and I’m proud to serve our country this way.

What’s your favorite outside of work activity and why?

I love working on home renovation projects. My favorites are electrical and landscaping. There’s something about these kinds of activities that help me unwind. There’s nothing like working with your hands to help de-stress.

What one thing would your coworkers be surprised to know about you?

Several years ago, some friends from college and I did a big bike trip from State College, Pennsylvania, to Burlington, Vermont. We traveled over 500 miles. The first day of the trip, I blew out my knee and had to decide whether to go home or keep going. I persisted and rode over 400 miles on a bad knee. Although there was a little bit of pain, it was worth it in the end.

Take a few minutes and learn about David Zakrzwski, CNS’s Information Solutions and Services deputy chief information officer at Y-12. All views and opinions are the employee’s and do not necessarily reflect those of CNS.

Technology is almost everywhere, requiring Information Solutions and Services to wear many hats at Pantex and Y-12. With each information technology division, including networking, cybersecurity, end user support, and applications management, IS&S is responsible for ensuring that any government technology we use on a daily basis, on site or at home, is running smoothly and securely.

As a key expert, leader, and direct support to Consolidated Nuclear Security Chief Information Officer Joe Harris, IS&S deputy chief information officer, David Zakrzwski, is integral to IS&S operations.

Why are you mission success?

Looking at the mission success model, I feel that my role in mission success is in the pillars of technology and innovation and infrastructure. For IS&S, those two pillars work together. The foundational infrastructure supports technology and innovation that enable new capabilities for our production and all supporting organizations.

Are you doing what you envisioned as a young adult? If so, describe how you got here.

No, I grew up in a family of engineers. My father was an engineer and four out of my five brothers studied engineering. My plan was to be an electrical engineer in the communications industry. While I was earning my degree in electrical engineering, I worked part time with the company my father was working for doing computer-aided drafting. I found the Information Technology department didn’t know how to support PCs at the time, so I learned it myself. By the time I finished my degree, I found I had a real passion for IT and that’s when my career path changed. I spent most of my career in networking and then moved into project and program management.

What’s your top bucket list item and why?

A vacation to Italy would be one of my top bucket list items. I’m fascinated by the architecture and history of the cities of Rome and Venice.

Rack framed and wrapped for shipment at supplier’s facility

Racks, or “multi-commodity pipe rack modules,” are one of the many components that go into building the Uranium Processing Facility. Achieving 100% rack delivery required tremendous effort and planning, but the team completed the feat ahead of schedule.

The magnitude of the task was considerable, including processing and reviewing thousands of documents and coordinating consistent communication with the supplier. The team’s efforts paid off with a smooth acquisition and delivery process.

Overall, the team procured 295 racks at a total cost of approximately $60 million. Hitting 100% rack delivery opens up many work fronts for construction, allowing them to stay on schedule and move to the next goal.

The first request for proposals (RFP) for the racks was issued in August 2018 and awarded in February 2019. The last delivery was in summer 2021. The team is evaluating lessons learned throughout the three-year journey that can be used in the future.

“One-hundred percent rack delivery means we are one step closer to completing UPF. Finishing this enormous endeavor ahead of schedule displays how hard our team has worked to achieve our goals; in fact one of our critical 2021 UPF goals. Thank you to everyone who dedicated their time and efforts to design, procure, and receive these essential elements in building our nation’s UPF,” said Dena Volovar, UPF Project Director.

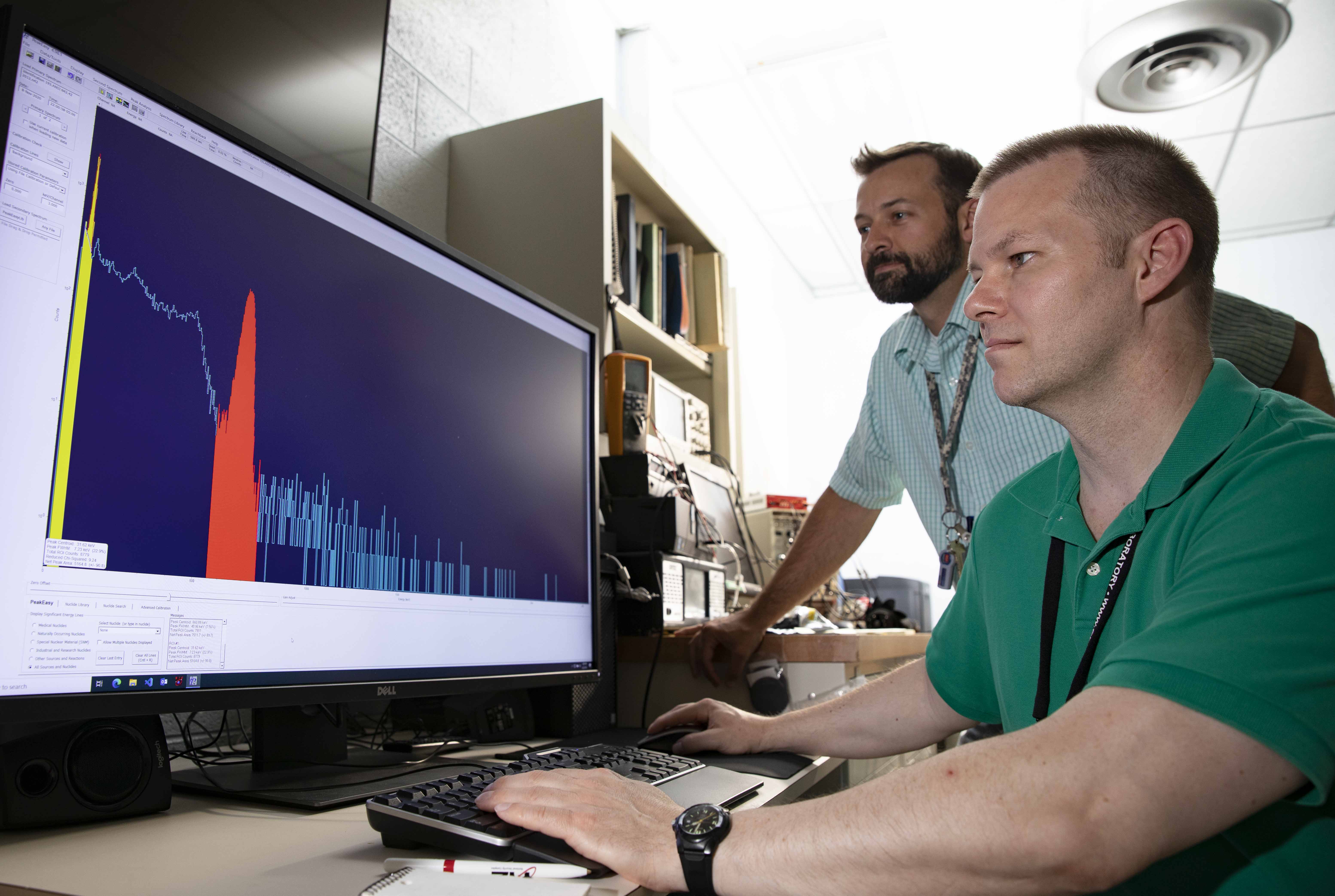

Brandon Grogan (right) from Oak Ridge National Laboratory is the most recent participant in the Mid-Career Professional Exchange project sponsored by National Nuclear Security Administration’s Office of Nonproliferation and Arms Control. The project seeks to provide production experience to researchers. Jeff Preston (left) of Y-12 Development served as Grogan’s mentor.

Oak Ridge National Laboratory (ORNL) and Y-12 National Security Complex (Y-12) both trace their history to the Manhattan Project, and both play important roles when it comes to international nuclear safeguards. International nuclear safeguards are a set of technical measures applied by the International Atomic Energy Agency on nuclear material and activities, through which the IAEA seeks to independently verify that nuclear facilities are not misused and nuclear material is not diverted from peaceful uses.

The Mid-Career Professional Exchange project, sponsored by the National Nuclear Security Administration’s (NNSA’s) Office of Nonproliferation and Arms Control, seeks to educate researchers through a production experience. This project provides ORNL staff members a fresh perspective by giving them working-facility experience and mentorship with a facility expert from Y-12. The ORNL employee leaves Y-12 with real-life applications for their current research and development ventures, and better prepared to serve the international safeguards community, while Y-12 is able to tap the employee’s expertise in areas such as computer modeling and nuclear detection.

Since 2018, Y-12 has hosted several exchanges. Brandon Grogan from ORNL's Material Security and Stewardship group is the most recent staff member to participate in this program.

According to Y-12’s principal investigator, Jason McCall, this exchange was very successful. “Brandon was able to complete an accelerated exchange, despite the challenges of COVID-19. He spent time in the Highly Enriched Uranium Materials Facility and our other production and fabrication facilities, and he was able to learn a lot of new skills that are directly applicable to international nuclear safeguards.”

Research vs. production

With a B.S. in Physics from West Point and an M.S. and Ph.D. in nuclear engineering from the University of Tennessee, Knoxville, Grogan has the academic bona fides. He’s been at ORNL since 2006, starting as a graduate research assistant. He is now a staff researcher, and his interests include nuclear forensics, international safeguards, non-destructive measurements, and inverse methods.

The career exchange allows Grogan to add some production experience to his impressive academic résumé before he goes to his next assignment as a technical advisor for the Nuclear Materials Information Program in Washington, D.C.

Jeff Preston of Y-12 Development served as Grogan’s mentor. “Brandon had visited a few other sites, but he had not worked in the production areas, so this exchange allowed him to see how a production facility operates. While he is going to an M&O (management and operating) position immediately afterwards, I believe the experience here will help shape how he approaches his role regarding production sites.”

Give a little, gain a little

As a “computer modeling guy,” Grogan brought some unique skills to Y-12. “I can model things that are too expensive or too dangerous to measure,” he said. The results of his computer simulations provided unique insights into Y-12 materials for various radiation detection applications.

While working in Development, he focused on a system for measuring oxygen content in various materials. The previous system was assembled in the 1990s, and replacement parts are no longer available. Grogan’s goal was to develop models for new system designs. With these models, Preston’s team will be able to select and purchase components for the new system, confident that it will achieve the same measurement fidelity as the old one.

The bottom line

“The career exchange is a good program that provides cohesiveness and team building between NNSA and Office of Science laboratories,” said Preston. “Office of Science personnel rarely obtain an in-depth view of an NNSA production facility given need-to-know and other limitations. The program enables a cross-pollination between labs and production sites that can better align strategic goals.”

As the Y-12 program lead, McCall wants these mid-career exchanges to be formative. “I hope Brandon’s experience at Y-12 contributes to his success throughout his safeguards career,” he said.

“It’s definitely been worthwhile,” said Grogan. “We (researchers) do all this theoretical stuff, and we sometimes forget what a production environment looks like.”

ORNL’s program lead, Jessica White-Horton, further touts the exchange: “When the participants return to ORNL, they are reinvigorated and communicate about how much they have learned! Some things simply cannot be taught in a classroom.”

All community colleges are expected to educate and train students to prepare them for a future career, but Roane State Community College goes a step further. At its Harriman campus, Roane State established the Raider Pantry, a facility that provides supplies for students dealing with the issue of food insecurity.

“It’s difficult to be your best in class if you’re worrying about feeding your family or yourself,” said Karen Brunner, RSCC’s vice president of institutional effectiveness and a co founder of the food pantry project. “Since September 2019 when we opened the pantry, hundreds of students, their children, and other family members have been served.”

With the pandemic creating a national emergency, the need for food increased as many families struggled with their finances. Through the Neighbor to Neighbor Fund, a $2,500 grant from CNS was matched with a $2,500 grant from East Tennessee Foundation, which provided much needed support for RSCC’s COVID-19 crisis response.

With many students learning from home amid the pandemic, RSCC hosted “Food Pantry On the Go” events that attracted students and their families who might not otherwise have been able to take advantage of the service.

“We had one student who drove in for the event and she had her kids with her,” said Dr. Lisa Steffensen, RSCC’s dean of students and a food pantry organizer. “We helped her pick out some items and made sure the kids got to help pick cereal and a dessert item to take with them. As they were leaving, one of the kids yelled from the back seat, ‘Thank you for helping us.’ It just really hit home how much these meals mean to our students and their families.”